- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

1263

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Vpromatchx

-

Model Number:

-

Body Filler MP44

-

Substrate:

-

Multifill Perfect filling on zinc, aluminum and steel

-

Advantage:

-

Competitive Prices

-

MOQ:

-

12 Liters

-

Package:

-

1L*12tins / Ctn or 3.75L*4 tins/ctn

-

application for:

-

for bare metal

-

Pot Life:

-

'8-15 minutes@20℃

-

Drying Time:

-

'50-60 minutes@20℃

-

special notice:

-

Do not apply topcoat on putty directly

-

Scrape method:

-

Scrape directly, volatile time for each layer is 15 minutes

-

The single-component putty is:

-

type of quick-drying filling material for patching

Quick Details

-

CAS No.:

-

1263

-

Other Names:

-

Auto Refinish

-

MF:

-

1263

-

EINECS No.:

-

1263

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Vpromatchx

-

Model Number:

-

Body Filler MP44

-

Substrate:

-

Multifill Perfect filling on zinc, aluminum and steel

-

Advantage:

-

Competitive Prices

-

MOQ:

-

12 Liters

-

Package:

-

1L*12tins / Ctn or 3.75L*4 tins/ctn

-

application for:

-

for bare metal

-

Pot Life:

-

'8-15 minutes@20℃

-

Drying Time:

-

'50-60 minutes@20℃

-

special notice:

-

Do not apply topcoat on putty directly

-

Scrape method:

-

Scrape directly, volatile time for each layer is 15 minutes

-

The single-component putty is:

-

type of quick-drying filling material for patching

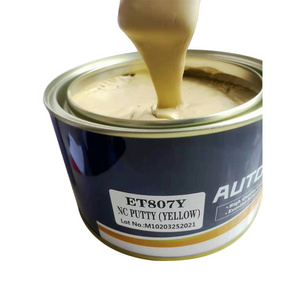

Single-component Filler (red plaster, putty)

The single-component putty is type of quick-drying filling material for patching sand paper scratches and minor dent. Excellent coverage and easy to hide small flaws,suitable to cover sand holes and pinholes. easy to apply and sand

Most of the filler should be sanded out. Only 2-5% of spreading area could be left.

The filler is not suitable to apply directly on bare metals.

Spray topcoat directly after sanding in case of small area application. For large areas,

it is recommended to use 2K primer surfacer prior to topcoat.

Please seal the can tightly after use to avoid skinning.

| MP44 Red filling putty | ||||||||

|

Characteristic: |

is suitable for fast filling small cracks and air cells

and small scratches. It can be sprayed on primer or filling materials |

|||||||

|

Scrape

method |

Scrape directly, volatile time for each layer is 15 minutes | |||||||

| Substrates |

1. Clean surface of 1-pack or 2-pack primer.

2. The surface of well applied polyester putty. 3. Not suitable for nude iron steal surface. It cannot be used as putty. |

|||||||

| Drying Time | 20 minutes@20℃ | |||||||

|

Shelf Life |

2 years since the production date if sealed and kept in a cool and dry place | |||||||

| Package | 1L*12 cans/carton or 48 PCS * 300G/carton | |||||||

The main components of paint include the following five major parts:

(1) Oils: including dry and semi dry oils, are one of the main film-forming substances

(2) Resin: including natural resin and artificial resin, it is also a part of the main film-forming substances

(3) Pigments: including coloring pigments, physical pigments, and anti rust pigments, with a wide variety of specific varieties, which are secondary film-forming substances

(4) Diluents: including solvents and diluents, used to dissolve the above-mentioned substances and adjust the viscosity, as auxiliary film-forming substances

(5) Auxiliary materials: includ

Application& Characteristic

: This product is multi-purpose polyester putty, matched with BPO hardener. It has property of quick air drying, refined graybody good temperature variation resistance, outstanding application, no sandholes, shrink holes after drying, smooth and glossy after construction, strong water resisting property, and distinctive anti-low&high temperature property,

Scope of construction: It can be used in iron panel, steel plate, aluminum plate, aluminum alloy plate, galvanized sheet, FRP and on any painted metallic surfaces.

ing drying agents, curing agents, plasticizers, moisture-proof agents. They also belong to auxiliary film-forming substances

MP39-1 resistant to 230 ℃ high temperature putty,high temperature putty for powder

Professional Series Body Filler makes auto repairs easier and faster

| Product Overview | ||||||||||

| The ratio of unsaturated polyester resin, modified resin, pigment, filler, auxiliary and curing agent is 100: 2. | ||||||||||

| Product Features | ||||||||||

| Resistance to baking at 220-230 ℃, no cracking, no foaming, good coating, good sanding, fast natural drying, etc. | ||||||||||

| Product technical indicators | ||||||||||

| Air dryness: meet customer requirements | ||||||||||

| Consistency: 9-12CM | ||||||||||

| Flexibility: ≥100MM | ||||||||||

| Impact strength: ≥30KG.CM | ||||||||||

| High temperature resistance: baking at 230 ℃ for 2 hours without cracking or foaming | ||||||||||

| Adhesion: ≥2.5MPa | ||||||||||

| Construction parameters | ||||||||||

| The main putty and curing agent should be mixed in a ratio of 100 to 2 and must be mixed uniformly. | ||||||||||

| Application area | ||||||||||

| putty for high temperature baking coating of hardware, machinery, furniture, door industry, hood, etc. | ||||||||||