- Product Details

- {{item.text}}

Quick Details

-

Power:

-

50-130kw

-

Dimension(L*W*H):

-

according to customer's requirements

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product name:

-

drill pipe/tube cleaning machine

-

Size of cleaning piece:

-

30-2000mm

-

Abrasive flow rate:

-

2*250 kg/min

-

Noise level:

-

≤90dB

-

Name:

-

Shot Blasting Machine

-

Function:

-

Metal Rust Surface Cleaning

-

Blast wheel:

-

turbines

-

Dust collector:

-

Baghouse

-

Advantages:

-

High Performance

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QINGDAO ANTAI

-

Weight (KG):

-

20000 KG

-

Power:

-

50-130kw

-

Dimension(L*W*H):

-

according to customer's requirements

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product name:

-

drill pipe/tube cleaning machine

-

Size of cleaning piece:

-

30-2000mm

-

Abrasive flow rate:

-

2*250 kg/min

-

Noise level:

-

≤90dB

-

Name:

-

Shot Blasting Machine

-

Function:

-

Metal Rust Surface Cleaning

-

Blast wheel:

-

turbines

-

Dust collector:

-

Baghouse

-

Advantages:

-

High Performance

Steel Pipe /tube inner/outer Wall Shot Blasting Machine

Steel pipe shot blasting machine is widely used for metal gridding, steel tube, petroleum, chemical, electric power industry, steel, city centralized heating, centralized drainage.

The steel pipe inner/outer wall special purpose shot blasting machine is suitable for cleaning inner/outer surface of steel pipes, remove the scales and weld dregs, make it show metal color, increase its ratio surface and weld dregs, make it show metal color, increase its ratio surface area, and thus contribute to painting and coating.

The Steel Pipe Shot Blasting Machine uses high-speed blast to strike and cut the surface of the work piece in dry and non-fluid media, and realize the cleaning purpose.

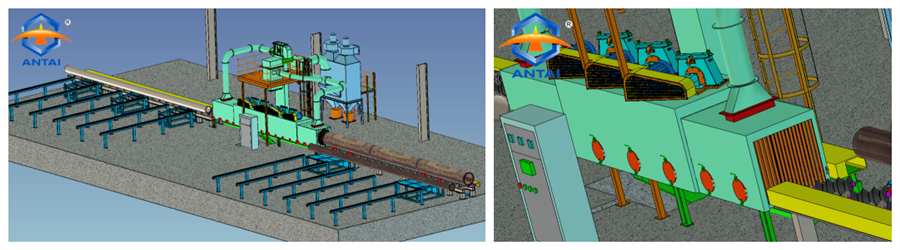

Steel Pipe Outer wall shot blasting machine

The external/outer pipe shot blasting machine can removal the oxide scale, rust and other sundries from the pipe outer and inner to have a good effect of derusting, reach the national standard of SA2-SA3 in SR/TQ414-98. It can improve the tensile and compresive resistance of the pipe surface and can also possess the reliable depth of abrasion pattern, so as to get strong adhesion of the coating on the pipe with a satisfying result of anticorrosion and therrmal insulation. Meanwhile, the derusting speed can be adjusted as 1-6m/min according to different types.

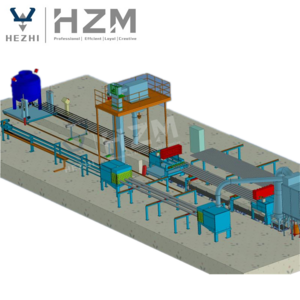

Steel pipe/tube external wall shot blasting machine 3D drawing

Steel pipe outer wall shot blasting machine projects

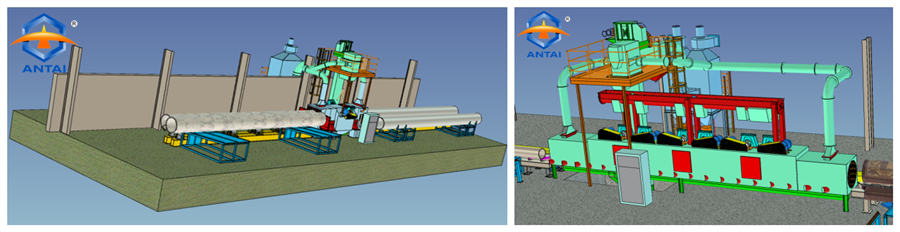

Steel Pipe Inner

wall cleaning

Sand

blasting machine

This machine adopts hydraulic, electric impeller head or air pressure grit-blasting gun to eliminate rust, oxide coating, welding slag for internal pipes to make the surface appear metallic sheen, increasing the surface area. The derusting efficiency is 80-150m2/h and the surface preparetion level reaches 2.5-3. According to the different diameter, derusting equipment for internal pipes can be equiped with single-gun, double-gun, four-gun, six-gun and eight-gun sand tank. Used for the diameter range: Dia48-1000.

Steel Pipe Inner Sandblasting machine composed of pipe-rotating machine, grit-blasting trolley, grit-blasting head, grit-graying machine, grit-recycling line, specialized trolley for internal coating, grit-collecting box, grit separator, dust-removing system and operating platform, with many models to choose.

steel pipe/tube inner wall sand blasting machine 3D drawing

Use turbine/blast wheel clean big size steel pipe inner wall

Use sand blasting machine/pot clean smaller size steel pipe inner wall

Technique parameter

| Parameter | Cleaning Size (mm) | Cleaning Speed (m/min) | Function |

| QGW100 | 50-300 | 2-10 | Outer Wall of Shot blasting Machine |

| QGW720 | 159-720 | 2-6 | |

| QGW1200 | 219-1016 | 1-6 | |

| QGW1500 | 325-1600 | 1-6 | |

| QGW2800 | 1016-2800 | 1-2 | |

| QGN100 | 50-300 | 1-4 | Inner Wall of Shot blasting Machine |

| QGN700 | 325-720 | 1-2 | |

| QGN1000 | 720-1016 | 1-4 | |

| QGN1500 | 1016-1500 | 1-4 |

Advantages

1. Wide application, Easy to install and use.

2. Customized, Meet your needs.

3. Good stability, Low failure rate (technical maturity, technical precipitation, skilled workers).

4. Exquisite appearance (mature craft).

5. Large factories, Prompt delivery.

6. Strict quality inspection department.

7. Factory direct selling with competitive price.

8. Over 28 years’ shot blasting machine design experience.

9. Professional design team to serve you.

10. Mainly electrical control system adoptsinternational brand.

11. CE, ISO9001, ISO14000 certificate assure you our quality.

12. The feeding machine in this line has many models. This line is suitable for pipes with a wide range of size.from dia 48 mm to 1000mm(inner). from dia 500 mm to 2500mm(outer).

13. The whole line gets low noise and the staffing dust-collecting equipment is energy efficient, meeting the state requirement for environmental protection.

14. It is convenient to provide sand and one-time added sand can be used for lone time.

15. Simple installation, easy for transportation and convenient maintenance.

16. Easy to operate and simple to learn, automatic to control and reliable to perform.

If the machine is not suitable for your workpiece, please tell us the following infromation:

1) What kind of workpiece will you clean?

2) The size of workpieces(length, width and height of maximum workpiece,Length, width and height of minimum workpiece?)

3) How many the weight of maximum and minimum workpiece?

4) Please tell us your requirement cleaning efficiency?

According to your infomation, the most suitable machines will be designed for your workpieces.