- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

2.2

-

Range of Spindle Speed(r.p.m):

-

750 - 2800 r.p.m

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Welldone

-

Voltage:

-

100-300V

-

Dimension(L*W*H):

-

4200x1250x2700mm

-

Weight (KG):

-

250 KG

-

After-sales:

-

Field installation, commissioning and training

-

ServiceProvided:

-

Video technical support

-

After Service:

-

Spare parts

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Output (kg/h):

-

100 - 1000 kg/h

-

Feeding Size (mm):

-

1 - 10 mm

-

Output Size (mesh):

-

80 - 400 mesh

-

Power (kW):

-

2.2

-

Range of Spindle Speed(r.p.m):

-

750 - 2800 r.p.m

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Welldone

-

Voltage:

-

100-300V

-

Dimension(L*W*H):

-

4200x1250x2700mm

-

Weight (KG):

-

250 KG

-

After-sales:

-

Field installation, commissioning and training

-

ServiceProvided:

-

Video technical support

-

After Service:

-

Spare parts

-

After Warranty Service:

-

Field maintenance and repair service

Product Description

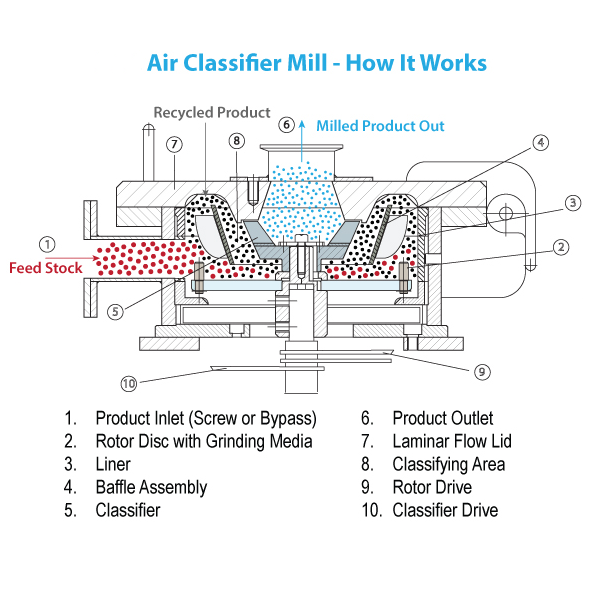

Working Principle

WFJ series air classifying mill pulverizer are high-energy vertical grinding mills incorporating an internal air classifying wheel to controll product particle size distribution.

Material is fed into the grinding chamber via screw feeder and strongly impacted and collided into fine powder between the high-speed disc rotor and teeth liner. After grinding process, fine powders are carried to the classifying section by airflow where qualified powders are suctioned into the interior of the classifying wheel and discharged as products; coarse powders flow through the inner guide ring back to the grinding chamber because of centrifugal force for re-grinding. Final product is collected by cyclone and bag house.

WFJ series air classifying mill pulverizer has been widely used for milling/pulverizing high fiber content materials, heat

sensitive materials and brittle materials in food, chemical and pharmaceutical industry.

Material is fed into the grinding chamber via screw feeder and strongly impacted and collided into fine powder between the high-speed disc rotor and teeth liner. After grinding process, fine powders are carried to the classifying section by airflow where qualified powders are suctioned into the interior of the classifying wheel and discharged as products; coarse powders flow through the inner guide ring back to the grinding chamber because of centrifugal force for re-grinding. Final product is collected by cyclone and bag house.

WFJ series air classifying mill pulverizer has been widely used for milling/pulverizing high fiber content materials, heat

sensitive materials and brittle materials in food, chemical and pharmaceutical industry.

Advantages

1. Size of output product:80-350 mesh

2. Capacity: 10-1200 kg/h

3. GMP design

4. Cyclone and bag filter are equipped.

5. Alloy steel hammer blades and rotor

6. Negative working condition can prevent dust and be suitable for heat sensitive material pulverization.

7. Output size is adjustable via air classifier and air flow rate.

8. Feeding rate is automatic controlled

9.Particle size distribution can be accurately controlled

Specification

WFJ superfine pulverizer is a superfine pulverizer consisting of three parts: main engine, auxiliary machine and electric control box. It has various characteristics such as air-selection, no screen, no net, uniform size and so on. The production process is continuous and extensive. Applicable to the crushing of materials in the pharmaceutical, chemical, food and other industries.

Hot Searches