PBT resin is polybutylene terephthalate, as one of the five general engineering plastics, mainly used in PBT modification, PBT wire drawing, film drawing, fiber sheathing and other fields, after enhanced modification can be widely used in automobile manufacturing, electronic and electrical, instrumentation, lighting appliances, home appliances, textiles, machinery and communications and other fields.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Qishen

-

Material:

-

polybutylece terephthalate

-

Color:

-

Nature

-

Type:

-

Compound

-

Grade:

-

Injection

-

DELIVERY TIME:

-

5-10 Days

-

Sample:

-

Aviable

-

Quality:

-

High Quality

-

Product name:

-

PBT plastic materials

-

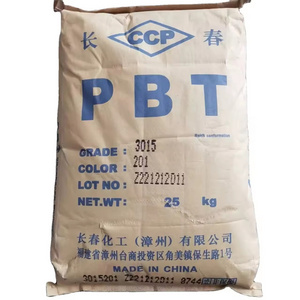

Package:

-

25 KG/Bag

Quick Details

-

color:

-

nature

-

Shape:

-

granules, Granular

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Qishen

-

Material:

-

polybutylece terephthalate

-

Color:

-

Nature

-

Type:

-

Compound

-

Grade:

-

Injection

-

DELIVERY TIME:

-

5-10 Days

-

Sample:

-

Aviable

-

Quality:

-

High Quality

-

Product name:

-

PBT plastic materials

-

Package:

-

25 KG/Bag

Products Description

PBT

Product Properties

Excellent mechanical properties, especially with high rigidity and hardness.

Good heat resistance, thermal deformation temperature can reach 180℃ or more.

Good surface gloss performance, especially suitable for non-spraying electronic and electrical products.

Fast crystallization speed, good fluidity, excellent formability

Good thermal stability, especially with low thermal expansion rate and dimensional shrinkage rate.

Good resistance to chemicals, solvents and weather.

High dielectric strength, good electrical performance.

Low hygroscopicity, minimal impact on electrical and dimensional stability.

When glass fiber is added to PBT, the bond between glass fiber and PBT resin is good. After adding a certain amount of glass fiber to PBT resin, it can not only maintain the original advantages of chemical resistance and processability of PBT resin, but also greatly improve its mechanical properties and overcome the notch sensitivity of PBT resin.

PBT is a crystalline aromatic polyester, if the flame retardant is not added, its flame retardant is UL94HB level, only after the addition of flame retardants, in order to reach UL94V0 level. Commonly used flame retardants are bromide, Sb2O3, phosphates and chlorides and other halogen flame retardants, the most is decabromodiphenyl ether, has been the main PBT flame retardants, but due to environmental reasons, European countries have long banned the use of all parties are looking for its alternatives, but there has been no performance advantages over decabromodiphenyl ether alternatives.

Product Application

Physical Property Report

|

PC/PBT FR K05

|

Test Method

|

Test Method

|

Value

|

Unit

|

||||

|

Physical Properties

|

|

|

|

|

||||

|

Density

|

23℃

|

ASTM-D792

|

1.26

|

g/cm³

|

||||

|

Shrinkage

|

|

ASTM-D955

|

0.7~1.2

|

%

|

||||

|

Melt Index

|

23℃

|

ASTM-D1238

|

/

|

g/10min

|

||||

|

Mechanical Properties

|

|

|

|

|

||||

|

Tensile Strength

|

5 mm/min, 23℃

|

ASTM-D638

|

54

|

Mpa

|

||||

|

Flexural Strength

|

13 mm/min, 23℃

|

ASTM-D790

|

80

|

Mpa

|

||||

|

Flexural Modulus

|

13 mm/min, 23℃

|

ASTM-D790

|

2000

|

Mpa

|

||||

|

Izod Notch Impact

|

3.2mm, 23℃

|

ASTM-D256

|

600

|

J/m

|

||||

|

Thermal Properties

|

|

|

|

|

||||

|

H.D.T

|

1.8MPa, 3.2mm

|

ASTM-D648

|

101

|

℃

|

||||

|

Flammability

|

1.6mm

|

UL94

|

V-0

|

|

||||

|

|

3.2mm

|

|

V-0

|

|

||||

Package & Delivery

25 kg/bag Standard package: Inner (Plastic film) and outer: (Paper bag or woven bag).

Or we can make it per customers' requirement.

Hot Searches