- Product Details

- {{item.text}}

Quick Details

-

Size:

-

50-200mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RZ

-

Model Number:

-

D

-

Viscosity:

-

standard

-

Product name:

-

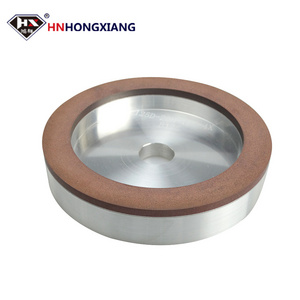

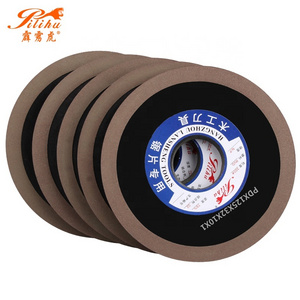

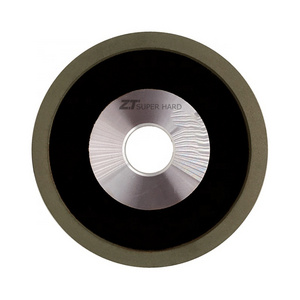

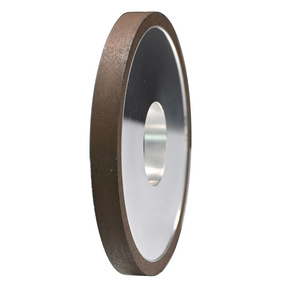

12A2 Resin Diamond Grinding Wheel

-

Type:

-

Tungsten Steel Carbide Tool Blade Grinding Wheel

-

Material:

-

Diamond

-

Model:

-

Saucer

-

Scope of application:

-

Ground alloy saw blade

-

Binding agent:

-

Resin grinding wheel

-

Craft:

-

resin

-

MOQ:

-

1PCS

-

OEM:

-

Accept

Quick Details

-

Application:

-

Aluminum, Deburring

-

Shape:

-

Flat-Shaped

-

Hardness:

-

standard

-

Size:

-

50-200mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RZ

-

Model Number:

-

D

-

Viscosity:

-

standard

-

Product name:

-

12A2 Resin Diamond Grinding Wheel

-

Type:

-

Tungsten Steel Carbide Tool Blade Grinding Wheel

-

Material:

-

Diamond

-

Model:

-

Saucer

-

Scope of application:

-

Ground alloy saw blade

-

Binding agent:

-

Resin grinding wheel

-

Craft:

-

resin

-

MOQ:

-

1PCS

-

OEM:

-

Accept

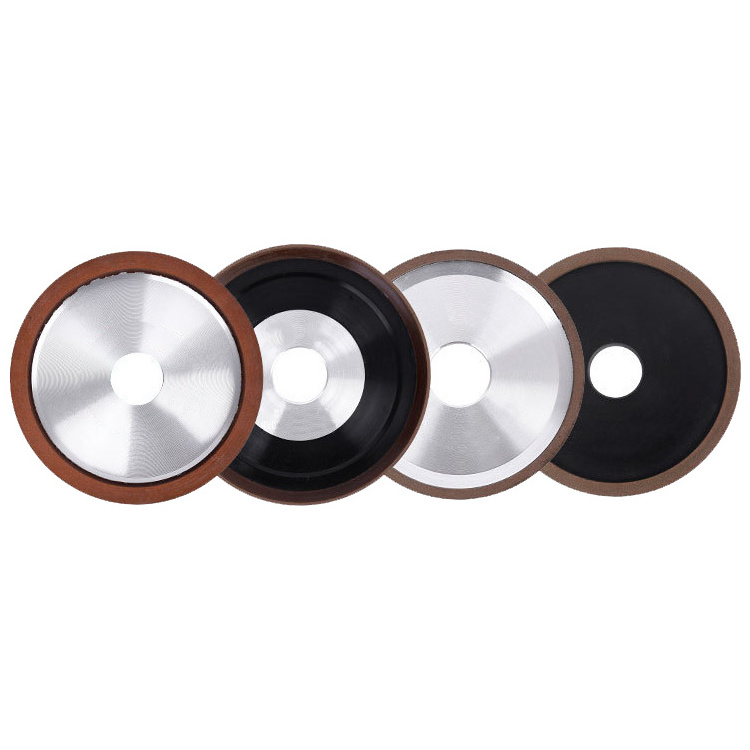

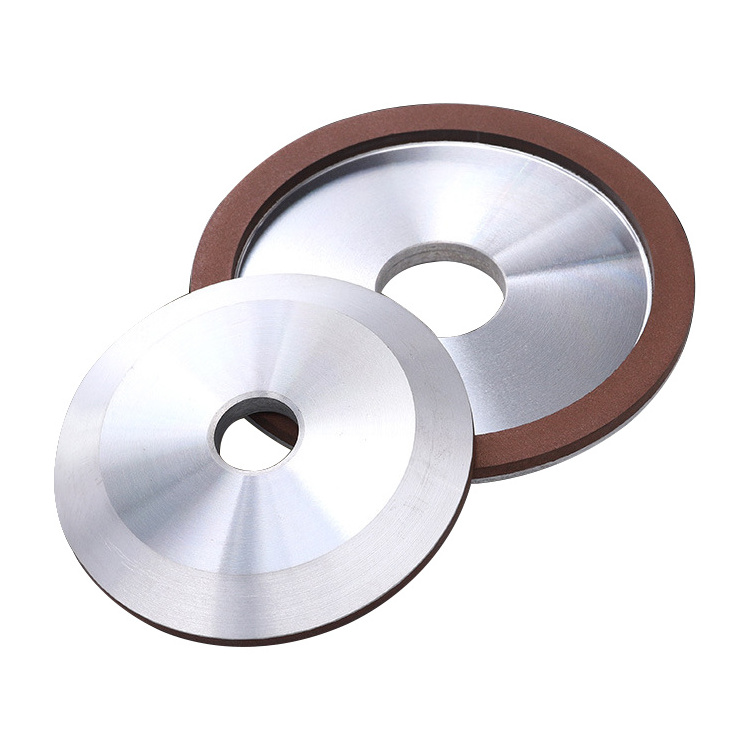

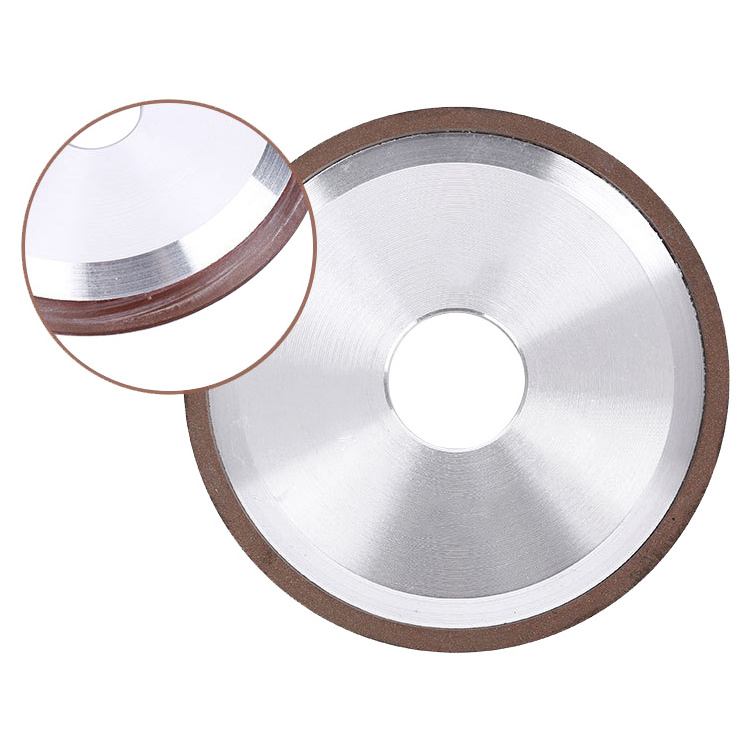

Products Description

Single beveled diamond resin grinding wheel

Mainly used for woodworking knives, carbide knives, saw blades, saw teeth processing and grinding, used with gear grinding machines.

Product material

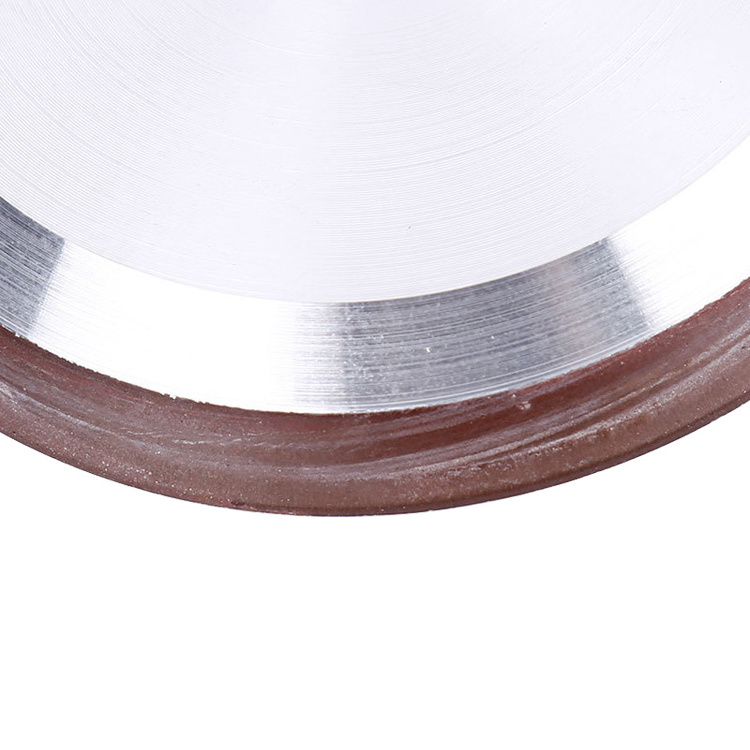

Abrasive: Diamond

Binder: Resin

Substrate: aluminum substrate, aluminum core bakelite (boutique), all bakelite (boutique)

Product concentration:

ordinary grinding wheel 75%, fine grinding wheel 100%, special requirements can be customized

Product mesh (grain size):

regular mesh of ordinary grinding wheel is 150 mesh, regular mesh of fine grinding wheel is 240 mesh

Product use:

grinding alloy saw blade, diamond resin grinding wheel for grinding low iron content metal and non-metal hard and brittle materials, such as cemented carbide, high alumina porcelain, optical glass, agate gemstone, semiconductor material, stone, etc.

Note:

It is recommended to add water when grinding, which can prolong the service life.

|

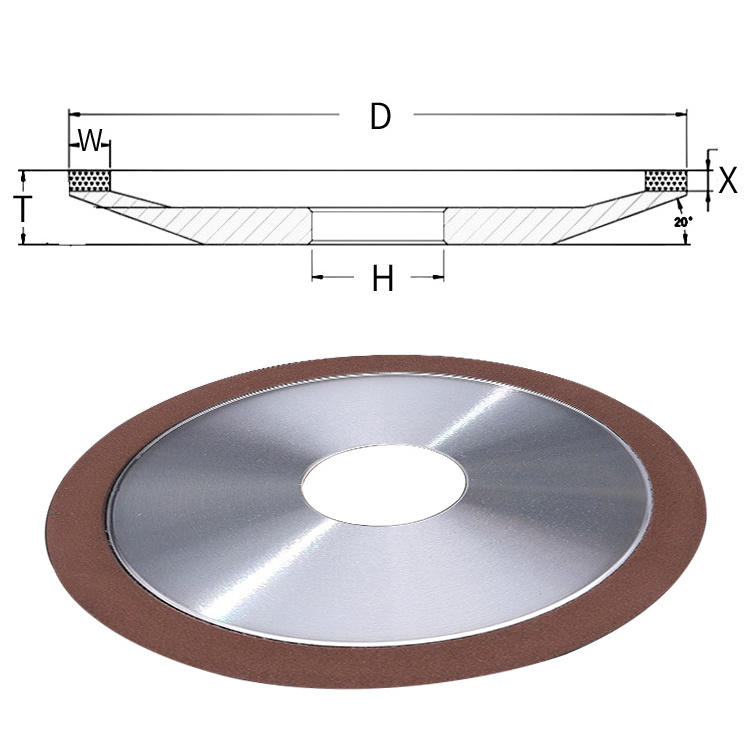

Product Name

|

Popular Sizes

D x T x H x W x X

|

D(mm)

|

T(mm)

|

H(mm)

|

W(mm)

|

X(mm)

|

|

D1 Resin Diamond Grinding Wheel

|

50*13*16*5*3

|

50

|

13

|

16

|

5

|

3

|

|

|

80*12*13*8*1

|

80

|

12

|

13

|

8

|

1

|

|

|

80*12*16*8*1

|

80

|

12

|

16

|

8

|

1

|

|

|

100*13*20*5*3

|

100

|

13

|

20

|

5

|

3

|

|

|

100*13*20*10*3

|

100

|

13

|

20

|

10

|

3

|

|

|

125*16*32*5*3

|

125

|

16

|

32

|

5

|

3

|

|

|

125*17*32*5*9

|

125

|

17

|

32

|

5

|

9

|

|

|

125*15*32*6*8

|

125

|

15

|

32

|

6

|

8

|

|

|

125*16*32*8*3

|

125

|

16

|

32

|

8

|

3

|

|

|

125*16*32*8*5

|

125

|

16

|

32

|

8

|

5

|

|

|

125*16*32*10*3

|

125

|

16

|

32

|

10

|

3

|

|

|

150*16*32*5*3

|

150

|

16

|

32

|

5

|

3

|

|

|

150*16*32*8*3

|

150

|

16

|

32

|

8

|

3

|

|

|

150*16*32*8*5

|

150

|

16

|

32

|

8

|

5

|

|

Full bakelite grinding wheel

|

150*16*32*8*7

|

150

|

16

|

32

|

8

|

7

|

|

|

150*16*32*10*3

|

150

|

16

|

32

|

10

|

3

|

|

|

200*20*32*10*3

|

200

|

20

|

32

|

10

|

3

|

|

D2 Resin Diamond Grinding Wheel

|

75*13*20*5*3

|

75

|

13

|

20

|

5

|

3

|

|

|

100*13*16*5*3

|

100

|

13

|

16

|

5

|

3

|

|

|

100*13*20*5*3

|

100

|

13

|

20

|

5

|

3

|

|

|

100*13*25*5*3

|

100

|

13

|

25

|

5

|

3

|

|

|

125*16*25*5*3

|

125

|

16

|

25

|

5

|

3

|

|

|

125*16*32*5*3

|

125

|

16

|

32

|

5

|

3

|

|

|

125*16*32*8*3

|

125

|

16

|

32

|

8

|

3

|

|

|

150*16*32*5*3

|

150

|

16

|

32

|

5

|

3

|

|

|

150*16*32*8*3

|

150

|

16

|

32

|

8

|

3

|

|

|

150*16*32*10*3

|

150

|

16

|

32

|

10

|

3

|

|

D3 Resin Diamond Grinding Wheel

|

125*10*32*10*2

|

125

|

10

|

32

|

10

|

2

|

|

|

150*16*20*10*2

|

150

|

16

|

20

|

10

|

2

|

|

|

150*10*32*10*2

|

150

|

10

|

32

|

10

|

2

|

Product Features.

1. Good self-sharpening and sharp cutting

2. High efficiency and high precision

2. High efficiency and high precision

3. Carborundum grains are uniform

4. High compressive strength

5. Good wear resistance

6. High grinding efficiency, smooth without chipping

7. Long service life

Selection of grinding wheel elements.

1.hard grinding material, choose the soft, fine grit grinding wheel. Soft grinding material, should choose a hard, coarse grit grinding wheel. By doing this ,grinding wheel loss is small, also not easy to plug.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of the grinding wheel.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of the grinding wheel.

Why Choose Us

Hot Searches