- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

RS

-

Model Number:

-

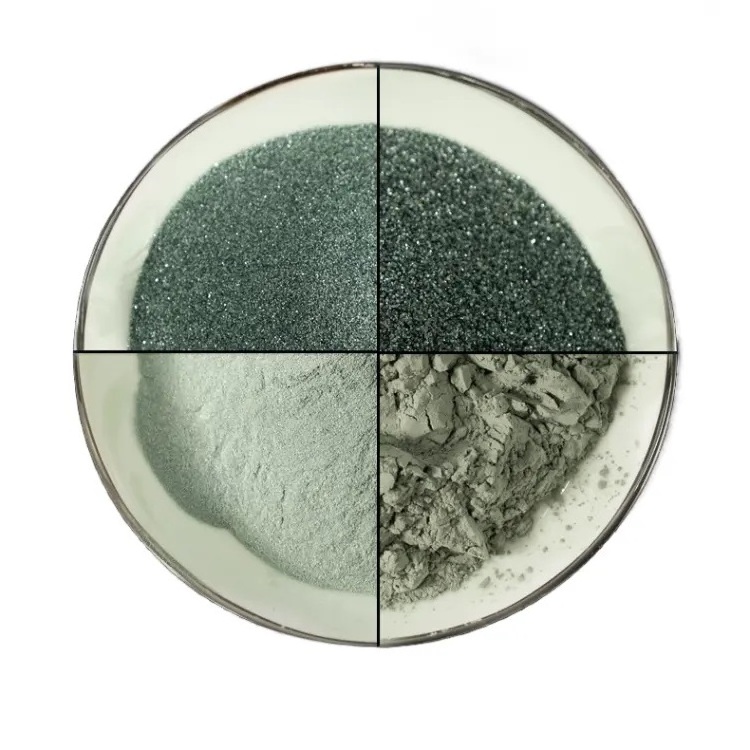

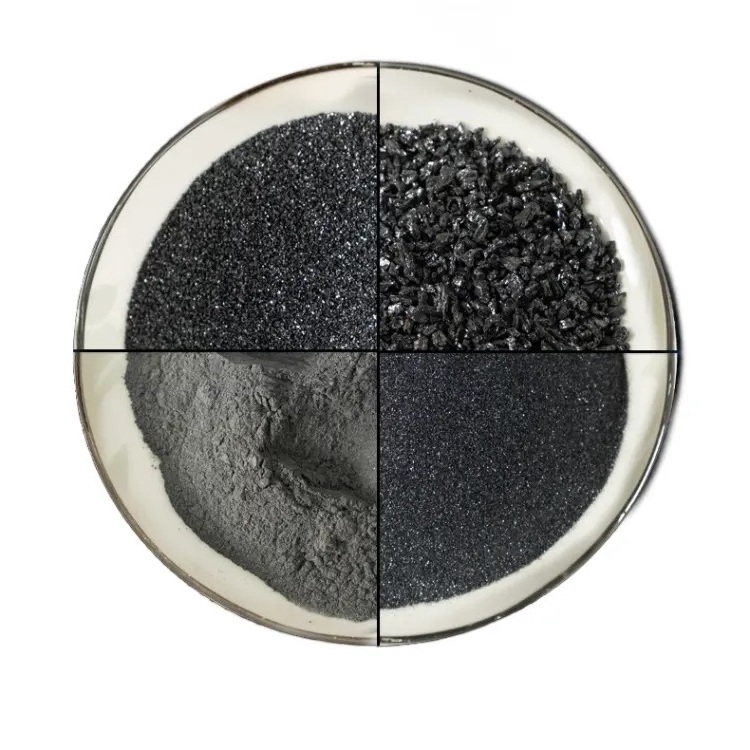

green & black silicon carbide

-

Usage:

-

Abrasives, advanced refractories, fine ceramics

-

Product name:

-

silicon carbide powder

-

Thermal Conductivity:

-

71-130 W/m.K

-

Bulk density g/cm3:

-

2.70-2.90

-

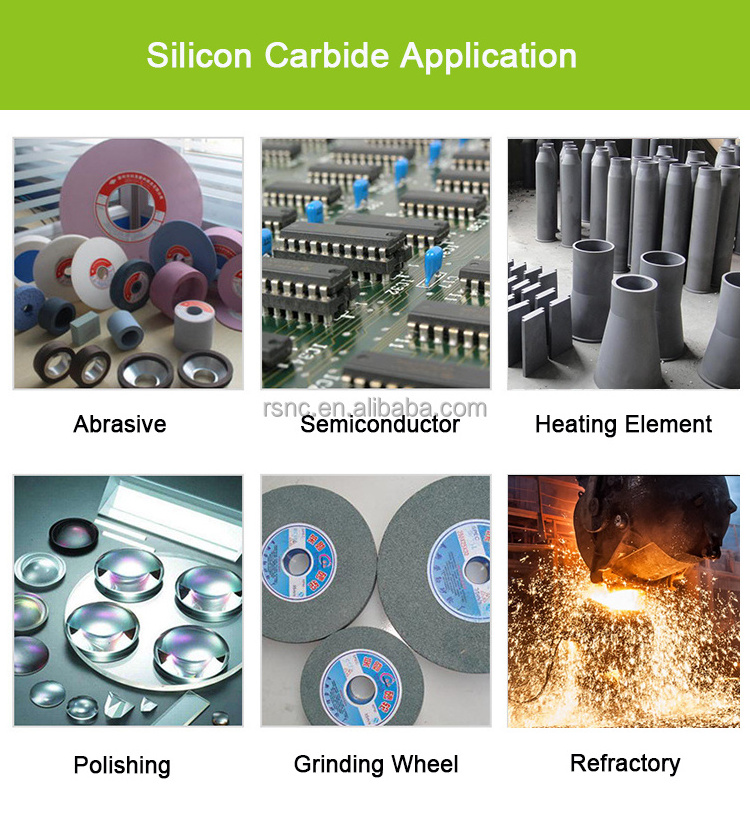

Application:

-

Refractory,Abrasive,Grinding And Polishing

-

Color:

-

green & black silicon carbide

-

Feature:

-

High Wear-resistance

-

Advantage:

-

high purity silicon carbide powder

-

Size:

-

Customized Size

-

Certificate:

-

ISO9001,CE

Quick Details

-

Type:

-

blasting media, silicon carbide powder

-

Abrasive Grain Sizes:

-

1-10mm and customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RS

-

Model Number:

-

green & black silicon carbide

-

Usage:

-

Abrasives, advanced refractories, fine ceramics

-

Product name:

-

silicon carbide powder

-

Thermal Conductivity:

-

71-130 W/m.K

-

Bulk density g/cm3:

-

2.70-2.90

-

Application:

-

Refractory,Abrasive,Grinding And Polishing

-

Color:

-

green & black silicon carbide

-

Feature:

-

High Wear-resistance

-

Advantage:

-

high purity silicon carbide powder

-

Size:

-

Customized Size

-

Certificate:

-

ISO9001,CE

Product Description

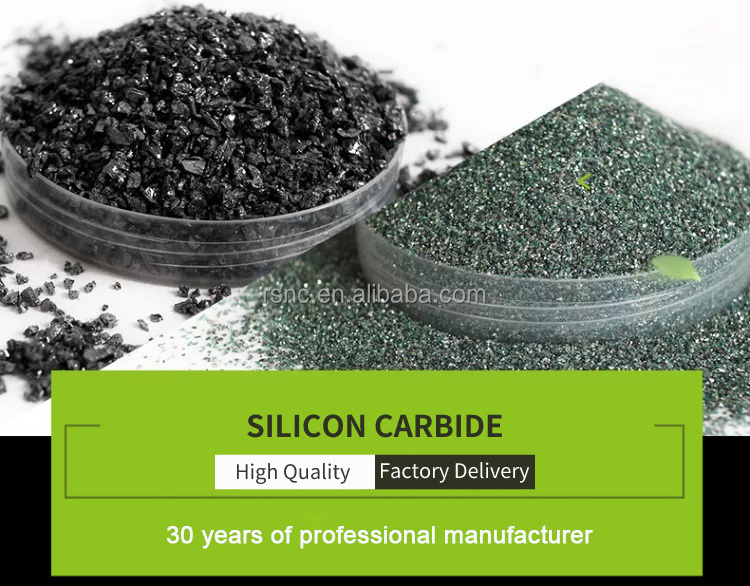

Green & Black Silicon Carbide

Silicon carbide includes black silicon carbide and green silicon carbide. Silicon carbide is made by melting quartz sand,Petroleum coke or Coal tar, wood chips, etc. in a high-temperature resistance furnace. Green silicon carbide is made by melting Petroleum coke and high-quality silicon dioxide as the main raw materials, adding salt as the additive, in a resistance furnace at high temperature. Its hardness is between that of corundum and diamond, its mechanical strength is higher than that of corundum, and it is brittle and sharp,has certain conductivity and thermal conductivity. Silicon carbide is one of the most widely used and economical materials, which can be called carborundum or emery carborundum.

Our Advantages

1. We are a manufacturer that is easier to control costs than trading companies, and we have a good understanding of technology to provide you with more support on technical issues.

2. Professional in abrasive production, with over 30 years of experience, complete product specifications, large production capacity, and short product delivery cycle.

3. A professional and experienced service team enjoys a good reputation among customers in both domestic and international markets.

Silicon Carbide Powder Properties

1.high strength

2.high thermal conductivity

3.has excellent thermal conductivity

4.high temperature resistant to oxidation

5.corrosion resistance

6.Silicon carbide is one of the most widely used and economical one

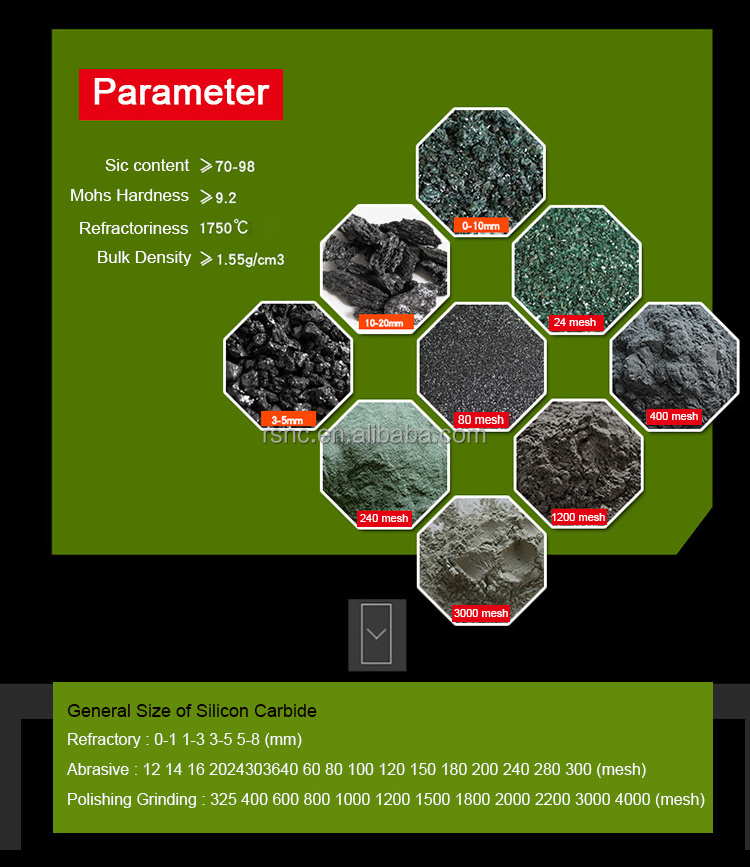

Product Parameters

|

Grit Size

|

Chemical Composition%(by weight)

|

|

|

||

|

|

SIC

|

F.C

|

Fe2O3

|

||

|

12#~90#

|

≥98.50

|

≤0.20

|

≤0.60

|

||

|

100#~180#

|

≥98.00

|

≤0.30

|

≤0.80

|

||

|

220#~240#

|

≥97.00

|

≤0.30

|

≤1.20

|

||

|

W63~W20

|

≥96.00

|

≤0.40

|

≤1.50

|

||

|

W63~W20

|

≥93.00

|

≤0.40

|

≤1.70

|

||

|

CHEMICAL CONTENT

|

|

|

|

SiC

|

98% min

|

|

|

SiO2

|

1% max

|

|

|

H2O3

|

0.5% max

|

|

|

Fe2O3

|

0.4% max

|

|

|

F.C

|

0.4% max

|

|

|

Magnetic Material

|

0.02% max

|

|

|

PHYSICAL PROPERTIES

|

|

|

|

Moh's Hardness

|

9.2

|

|

|

Melting Point

|

2300℃

|

|

|

Working Temperature

|

1900℃

|

|

|

Specific Gravity

|

3.2-3.45 g/cm3

|

|

|

Bulk Density

|

1.2-1.6 g/cm3

|

|

|

Color

|

Black

|

|

|

Elasticity Modulus

|

58-65x106psi

|

|

|

Coefficient of Thermal Expansion

|

3.9-4.5 x10-6/℃

|

|

|

Thermal Conductivity

|

71-130 W/m.K

|

|

|

Grain Size

|

|

|

|

0-1mm,1-3 mm, 3-5mm, 5-8mm,6/10, 10/18,200-0mesh,325mesh,320mesh,400mesh,600mesh,800mesh,1000mesh,

#24,#36,#46,#60,#80,#100,#120,#180,#220,#240...Other special spec. could be |

|

|

Product Application

Silicon Carbide Powder Applications

1.For abrasives, grinding of electronics, metallurgical additive.

2.For special ceramics, foam ceramics, modification of coating and plastics,

3.For auto parts, war industry and aviation, steelmaking

4.For abrasive and cutting tools and Cutting disks made of SiC

5.For grinding, honing, water-jet cutting and sandblasting.

6.For grinding non-ferrous materials, rock, stone, leather, rubber, hard materials

7.For bonded abrasive tools, lapping and polishing, metallurgical additive and Refractory material.

Product packaging

Packaging:

25kg/bag, two layers kraft bag with water proof, and with ton bag outside or each ton packed on a fumigation pallet according to customers' request.

Hot Searches