- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1600*1350*1600mm

-

Year:

-

2024

-

Power (kW):

-

2.2 kW

-

Weight (KG):

-

2000 KG

-

advantage 1:

-

user-friendly

-

advantage 2:

-

no leaking oil, no off pressure

-

heating way:

-

electric heating

-

pressure:

-

hydraulic station

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CGY

-

Voltage:

-

customer demand

-

Dimension(L*W*H):

-

1600*1350*1600mm

-

Year:

-

2024

-

Power (kW):

-

2.2 kW

-

Weight (KG):

-

2000 KG

-

advantage 1:

-

user-friendly

-

advantage 2:

-

no leaking oil, no off pressure

-

heating way:

-

electric heating

-

pressure:

-

hydraulic station

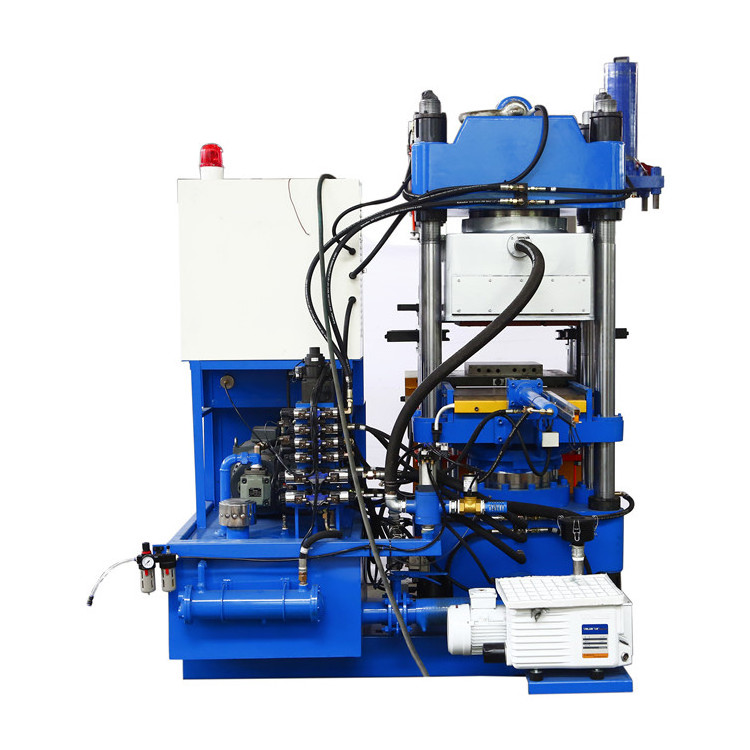

rubber stop block vulcanizing machine rubber curing press for tiles mats

The curing press mainly works for clampdown the rubber, which can be used as normal hydraulic machine .

1. Material of steel plate:

We use hight quality carbon steel Q-235(produce by Jigang Group Co.,Ltd which is a famous company) ,more thicker than other supplier,after shot blasting ,smooth, it is strong enough than common steel.

2.Weldment of frame : world technique

Welded together as a whole part,Stewing fire treatment after weldment.

(Carbon dioxide gas shielded welding,alloyed welding wire).

Submerged arc welding, VSR treatment after weldment.

3.Piston:

The material of plunger is Chilled cast iron, after polishing,grinding treatment and resist compression test,make the surface smooth,anti-abrasion,durable.

4 . Heating way&precision temperature control:

Steam ,oil or Electric (We use high quality hot platen and heating pipe to keep heating stability and uniformity) range of temperature:0-300 °C (can be adjustment if you need 400 °C ,we can do it ).

Plate temperature tolerance: ± 0.1°C (very precise)other factory just is ±3 °C.

Also we can produce the machine with water cooling system.

5.

Hydraulic system: (PLC control)

The professional hydraulic components, stable and reliable and quality .Pressure sensor control system pressure and never off pressure.

We use OMRON,SIMENS CHNT , SCHNEIDER ect brand electric parts.

6.There are more advanced technical information as our core patents ,and not showed in the description,please send email to us.

|

Parameters/version

|

XLB350*350*2 |

XLB400*400*2 |

XLB500*500*2 |

XLB600*600*2/4 |

XLB750*850*2 |

XLB1000*1000*2 |

|

Mould closing force |

0.25MN |

0.5MN |

0.8MN |

1.0MN |

1.6MN |

2.5MN |

|

Hot plate spacing |

125mm |

125mm |

125mm |

125mm |

125mm |

200mm |

|

Hot plate layer |

2 |

2 |

2 |

2/4 |

2 |

2 |

|

Plunger stroke |

250mm |

250mm |

250mm |

250/500mm |

250mm |

400mm |

|

Heating way |

Electricity/stream |

Electricity/stream |

Electricity/stream |

Electricity/stream |

Electricity/Stream |

Electricity/stream |

|

Main motor power |

2.2kw |

2.2kw |

2.2kw |

2.2kw |

3kw |

5.5kw |

|

The thermal power |

2.4kw/board |

3kw/board |

3kw |

7.5kw/board |

9kw/board |

10.8kw/board |

|

Size(L*W*H)mm |

1450*400*1350 |

1600*400*1440 |

1450*690*1818 |

1880*780*1660 |

2100*1010*1900 |

2400*960*2500 |

|

Weight(kg) |

1200 |

1500 |

1700 |

2500/3100 |

3560/4300 |

8300 |

Our packing way

:Export standard (wooden package ) or according to your requirement .

Our Services :

1. We will design,manufacture,install and test the machines according to customers' requirement .Relevant personnel training for customers,ensure that customers fully grasp the use and maintenance of technology.

2 .Our service department listen to customers' feedback at any time and provide spare parts timely. Welcome to visit our factory and we can show you the machine in working condition:

If our products win your interest, please send us inquires and we will provide detailed information to you. We can also make machines according to your request.

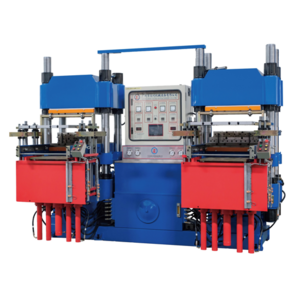

Pictures: Special design for different customers:

XK-160 open mixing mill and 80T vulcanizer

Common electric watch vulcanizer:

With box and two color automatic PLC control vulcanizer:

Digital watch semi-auto vulcanizer: 50T

Our plant and customers:

One layer heating and one layer water cooling for lab use:

Our plant and other machines: