- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

11Kw/h

-

Applicable Industries:

-

Lumber mills, Charcoal plant, Palm planting and deep processing, Food processing industry, Recycling of agricultural planting waste, Landscaping and wood processing

-

Weight (KG):

-

18000

-

Product name:

-

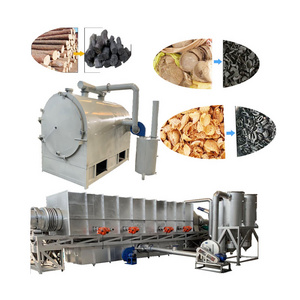

Rice Husk Charcoal Making Machine

-

Keywords:

-

Charcoal Making Machine

-

Application:

-

Making Charocal

-

Raw material:

-

Rice husk, straw, bits of wood, Palm Shell

-

Color:

-

Customer's Request

-

Final product:

-

Charcoal

-

Installation:

-

Engineer Guide

-

Advantage:

-

Continuous Working Environment Friendly

-

Service:

-

24hrs

-

Function:

-

Carbonization

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Beston Group

-

Dimension(L*W*H):

-

9m*6m*6m

-

Voltage:

-

380V

-

Power:

-

11Kw/h

-

Applicable Industries:

-

Lumber mills, Charcoal plant, Palm planting and deep processing, Food processing industry, Recycling of agricultural planting waste, Landscaping and wood processing

-

Weight (KG):

-

18000

-

Product name:

-

Rice Husk Charcoal Making Machine

-

Keywords:

-

Charcoal Making Machine

-

Application:

-

Making Charocal

-

Raw material:

-

Rice husk, straw, bits of wood, Palm Shell

-

Color:

-

Customer's Request

-

Final product:

-

Charcoal

-

Installation:

-

Engineer Guide

-

Advantage:

-

Continuous Working Environment Friendly

-

Service:

-

24hrs

-

Function:

-

Carbonization

Product Description

What is r ice husk charcoal making machine?

Rice husk charcoal making machine

refers to the machine that converts rice husk or other biomass materials into charcoal, wood vinegar, tar, biogas.

Why make charcoal from rice husks?

●.

Rice husks are produced in large quantities on the farm every year, so don't worry about over-utilization.

●. With high carbonization rate, you can get high-quality charcoal from rice husks.

●. Environmental Friendly, t here are no pollutants in the production process of charcoal.

●. With high carbonization rate, you can get high-quality charcoal from rice husks.

●. Environmental Friendly, t here are no pollutants in the production process of charcoal.

Raw Material – Rice Husk

Final Product – Charcoal

The charcoal making machine can be used to process rice husks and other various agricultural and forestry garbage, such as bamboo, straw, wood, sawdust, etc. Its final product, charcoal, is used in our daily life and in industrial production and agriculture.

Production Process

How to Produce Biochar with Beston Carbonization Furnace

▶ Feed the raw materials by a constant weight feeder into the carbonization host. If the water content of the materials is more than 25%, you must use a drying host to dry them at first. The perfect water content is below 15% in order to make sure a high quality of biochar.

▶ Preheat the carbonization host while feeding for about 30 minutes. During the pre-heating, the combustible gas will be generated and then recycled into fuel to supply heat for the carbonization host.

▶ The process of carbonization and pyrolysis of biomass waste happens as the temperature rises. Through desulfurization and dedusting, the clean biochar will be discharged. The whole process lasts about 15 min to 20 min.

▶ The flue gas/residual hot smoke will go through a strict filtering system in the water spraying tower with the functions of de-dusting, water washing, ceramic ring absorption and activated carbon absorption. Finally, it will be discharged outwards safely, meeting the EU Environmental Protection and Emission Standard.

Product Model

|

Model

|

BST-J12

|

BST-J18

|

BST-J40

|

BST-05 Pro

|

BST-10

|

BST-30

|

BST-50

|

|||||

|

Input Capacity

|

12m³/h/batch

|

18m³/h/batch

|

40m³/h/batch

|

0.3-0.5m³/h (300kg/h)

|

2-4m³/h (1000kg/h)

|

7-9m³/h (3000kg/h)

|

10-15m³/h (5000kg/h)

|

|||||

|

Reactor Size

|

φ1900mm*L4500mm

|

φ1900mm*L6600mm

|

φ2800mm*L7100mm

|

φ830mm*L5500mm

|

φ1300mm*L14051mm

|

φ1700mm*L14180mm

|

φ2000mm*L14260mm

|

|||||

|

Land for Equipment (L*W*H)

|

9m*6m*6m

|

12m*6m*7m

|

15m*18m*7m

|

10m*8m*3.9m

|

29m*15m*5m

|

30m*15m*8m

|

35m*18m*9m

|

|||||

|

Weight

|

18T

|

22T

|

34T

|

15T

|

35T

|

35T

|

49T

|

|||||

|

Energy Consumption

|

11kw/h

|

13.5kw/h

|

25kw/h

|

31kw/h

|

34.7kw/h

|

61.5kw/h

|

116kw/h

|

|||||

|

Working Method

|

Batch

|

|

|

Fully continuous

|

|

|

|

|||||

Main Parts

Conveyor-System

Crushing-System

Drying-System

Carbonization-System

Molding-System

Exhaust-Gas-Treatment-System

Packing & Delivery

Hot Searches