- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.2-0.8 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

customize

-

Dimension(L*W*H):

-

10500mm*1400mm*1500mm

-

Weight:

-

8500 kg

-

Feeding width:

-

customized

-

Usage:

-

Color Steel Construction for roofing

-

Company:

-

Zhongtuo

-

Pressing:

-

Hydraulic Guide Pillar

-

Cutting:

-

Hydraulic Guide Pillar

-

Transmission:

-

Chain Sprocket

-

Driving:

-

Electrical motor

-

Forming:

-

Rolling forming

-

Speed:

-

20 m/min

-

Control:

-

PLC Control

-

Advantage:

-

Easy installation;full automatic easy operation

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

roofing tile

-

Production Capacity:

-

15 to 20m/min

-

Rolling thinckness:

-

0.2-0.8 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

customize

-

Dimension(L*W*H):

-

10500mm*1400mm*1500mm

-

Weight:

-

8500 kg

-

Feeding width:

-

customized

-

Usage:

-

Color Steel Construction for roofing

-

Company:

-

Zhongtuo

-

Pressing:

-

Hydraulic Guide Pillar

-

Cutting:

-

Hydraulic Guide Pillar

-

Transmission:

-

Chain Sprocket

-

Driving:

-

Electrical motor

-

Forming:

-

Rolling forming

-

Speed:

-

20 m/min

-

Control:

-

PLC Control

-

Advantage:

-

Easy installation;full automatic easy operation

Product Description

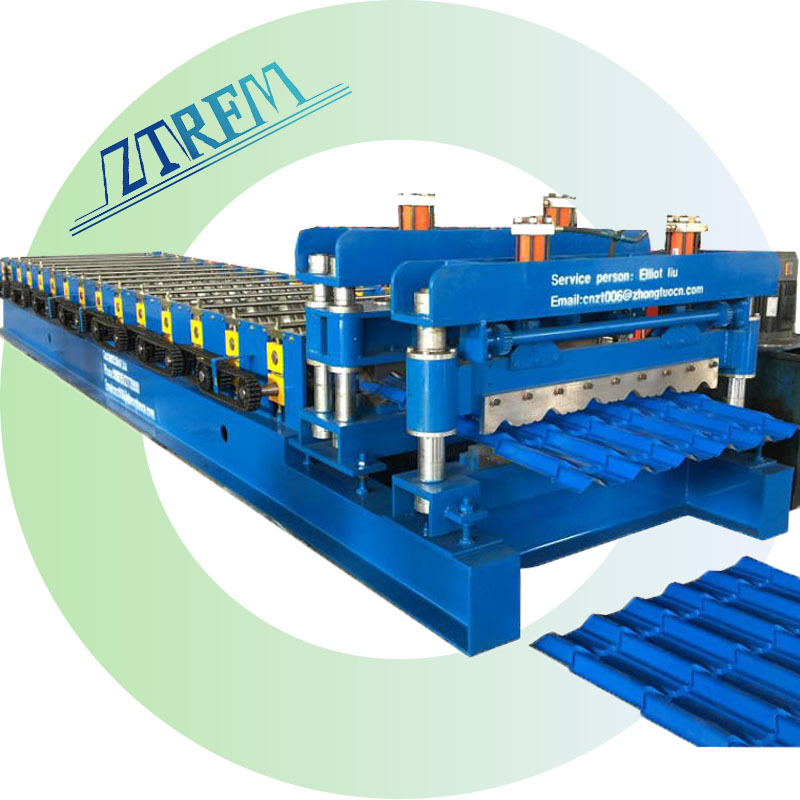

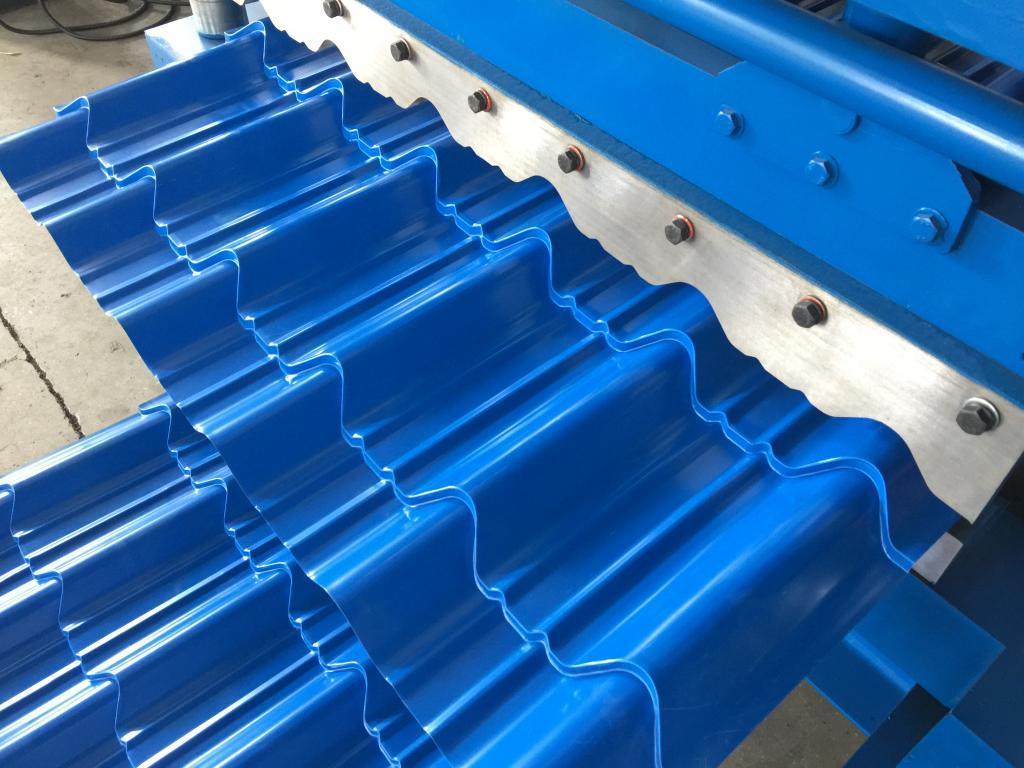

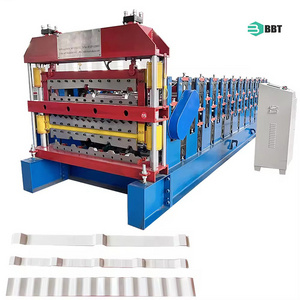

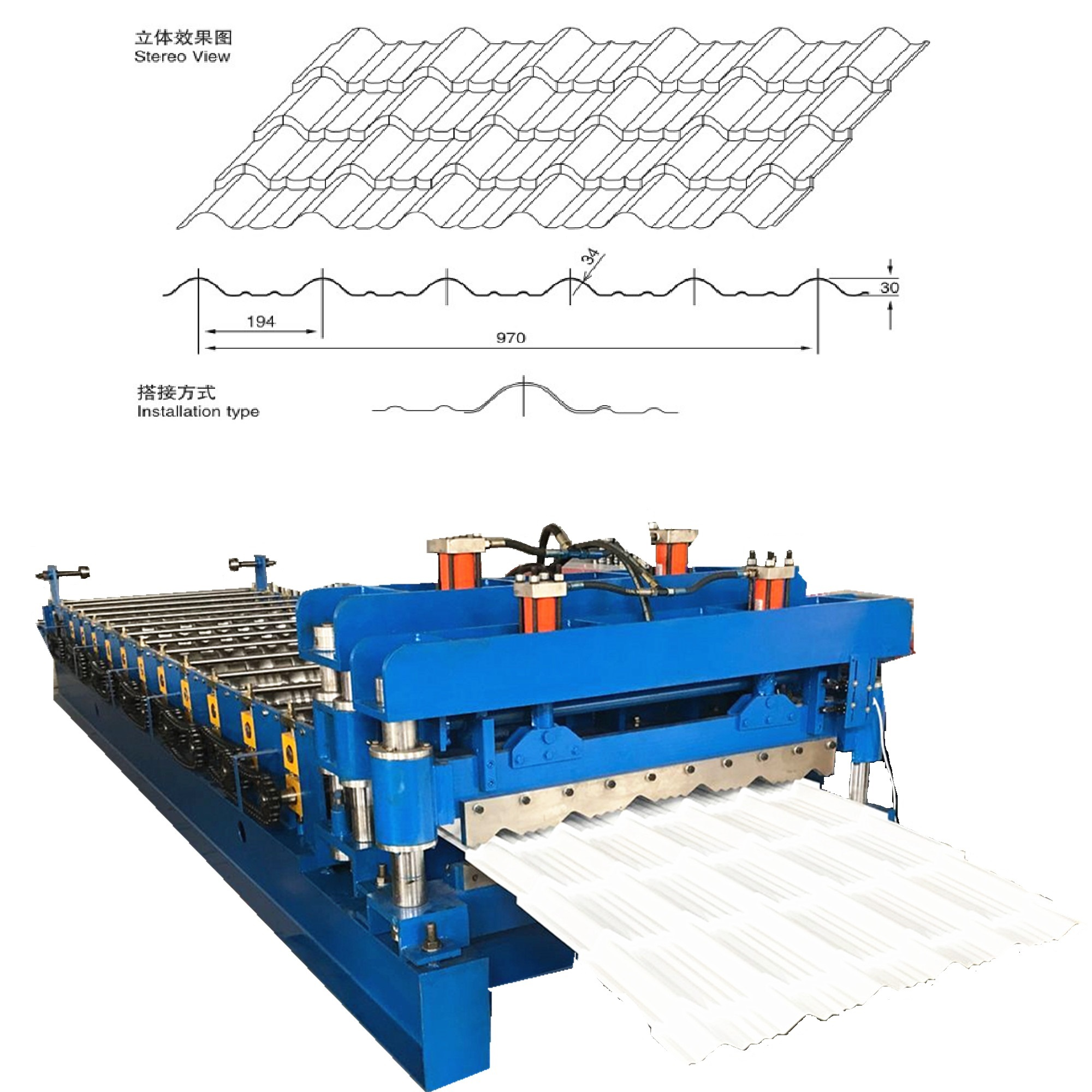

Metal Glazed Tile Roofing Sheet Making Machine Full Automatic Easy Installation 3D Effect Roof Sheet Roll Forming Machine

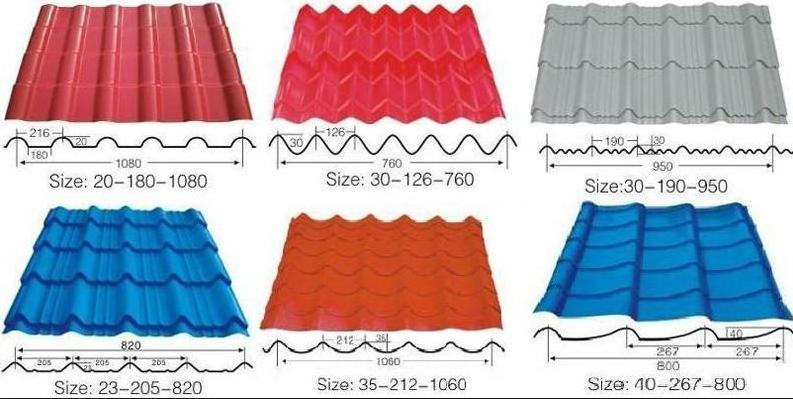

Glazed roofing sheet making machine with 3D effect it can help you control perfect 3D effict of the roofing. Compared with the normal roofing sheet machine, the glazed roofing tile making machine with one more steppnism. Take the following drawing profile for example:

Here one hot sale glazed roof sheet profile roll forming machine for your reference.

|

Metal glazed tile roofing sheet making machine full automatic easy installation 3D effect roof sheet roll forming machine

|

|

|

|

|

||||

|

1.Formed Material

|

PPGI,GI,AI,ZTRFM composite material

|

|

Thickness:0.18-0.8mm Width:1000mm/1250mm(customized)

|

|

||||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

|

Manual decoiler(will give you as free)

|

|

||||

|

3.Main body

|

Roller station

|

|

16 rows(As your requirement of profile)

|

|

||||

|

|

Diameter of shaft

|

|

80mm solid shaft

|

|

||||

|

|

Material of rollers

|

|

45# steel, hard chrome plated on the surface

|

|

||||

|

|

Machine body frame

|

|

400 H steel

|

|

||||

|

|

Drive

|

|

Gear and chain transmission

|

|

||||

|

|

Dimension(L*W*H)

|

|

15000*1800*1600(customize)

|

|

||||

|

|

Weight

|

|

8T

|

|

||||

|

4.Cutter

|

Automatic

|

|

cr12mov material, no scratches, no deformation

|

|

||||

|

5.Power

|

Motor Power

|

|

7.5KW* sets,Siemens brand

|

|

||||

|

|

Hydraulic system power

|

|

7.5KW

|

|

||||

|

6.Voltage

|

380V 50Hz 3Phase

|

|

As your requirement

|

|

||||

|

7.Control system

|

Electric Box

|

|

Customized(famous brand)

|

|

||||

|

|

Language

|

|

English(Support multiple languages)

|

|

||||

|

|

PLC

|

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|

||||

|

8.Forming Speed

|

15-20m/min

|

|

The speed is adjustable

|

|

||||

Products Display

What makes Zhongtuo glazed tile making machine is different with other?

1. Each hydraulic part, we will use two hydraulic jack to make sure the shearing more poweful.

2. We use the pillar post as the shearing pole, it can add oil more easily.

3. All the rollers we use the hard chroming, to make sure not damage the surface of the coil.

4. At the leveling part, we will add the filming system for the tile making machine.

5. And for the leveling part, we will manual cutter, hydraulic cutter or the others.

2. We use the pillar post as the shearing pole, it can add oil more easily.

3. All the rollers we use the hard chroming, to make sure not damage the surface of the coil.

4. At the leveling part, we will add the filming system for the tile making machine.

5. And for the leveling part, we will manual cutter, hydraulic cutter or the others.

gear and chain transmission-double chain for strong structure

Gcr12 mov hydraulic cutting device

Recommend Products

Why Choose Us

Hot Searches