- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

50 T

-

Power (kW):

-

450

-

Name:

-

Regenerative gas fired annealing furnace

-

Usage:

-

Heat treatment

-

Rated power:

-

Adjustable

-

Rated voltage:

-

380V/400V/410V/480V/550V

-

Rated temperature:

-

1200C

-

Furnace uniformity:

-

±10℃

-

Color:

-

Requirement

-

Certification:

-

ISO9001:2008

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XINTIANLI

-

Voltage:

-

380/420/440

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

50 T

-

Power (kW):

-

450

-

Name:

-

Regenerative gas fired annealing furnace

-

Usage:

-

Heat treatment

-

Rated power:

-

Adjustable

-

Rated voltage:

-

380V/400V/410V/480V/550V

-

Rated temperature:

-

1200C

-

Furnace uniformity:

-

±10℃

-

Color:

-

Requirement

-

Certification:

-

ISO9001:2008

Regenerative gas heating furnace

Product Description

Regenerative gas heating furnace has been applied in various kinds of annealing process, such as homogenizing annealing and full annealing, incomplete annealing, isothermal annealing, spheroidizing annealing, the recrystallization annealing or intermediate annealing, stress relieving annealing, etc.The trolley gas fired annealing furnace that we produces can meet the requirement of various annealing process, the application of human-computer interaction system on the furnace increases the controllability of the annealing process.The application of high speed burner ensures the temperature increases to the best annealing temperature according to the requirements of workpiece heat treatment.

Applications

Annealing furnace is mainly applied to various products with large framework,and commonly used for annealing heat treatment of welding parts ,the involved industries :complete body annealing for special car tanks , post weld heat treatment(PWHT) for the vessel or containers, at present ,the exsiting case is one natural gas furnace with sizes 20*4*5m has already been fabricated and pre-installed in our factory and exported to the United states.

Technical parameters

| TYPE | Furnace Theory Loading(T) | Burning control method | Rated Tep(℃) | Working Zone size(mm) | Gas consumption(Nm3/h) |

| RQT-3 | 3 | Pulse | 1100 | 2x1.3x1.2 | 20 |

| RQT-6 | 6 | 1100 | 2.6x1.5x1.4 | 32 | |

| RQT-12 | 12 | 1100 | 3.1x1.7x1.7 | 60 | |

| RQT-20 | 20 | 1100 | 4x2x1.9 | 120 | |

| RQT-30 | 30 | 1100 | 5x2.5x2.3 | 160 | |

| RQT-60 | 60 | 1100 | 6x3x2.8 | 240 | |

| RQT-120 | 120 | 1100 | 8x4x3.5 | 300 | |

| RQT-180 | 180 | 1100 | 8x6x4 | 380 | |

| RQT-230 | 230 | 1100 | 10x5x5 | 420 | |

| RQT-300 | 300 | 1100 | 15x7.5x7.5 | 600 |

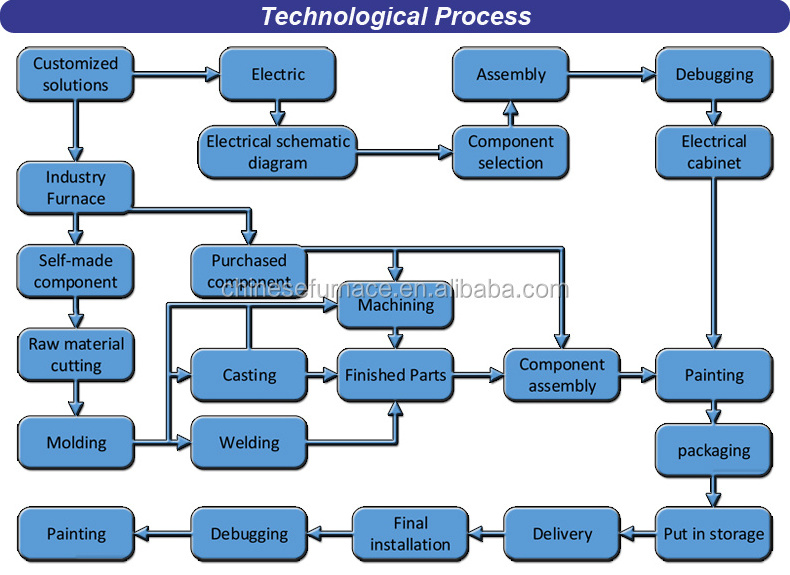

Technological process

Installation and trial start

1. For small furnace ,we will finish the installation and debugging of the furnace in our factory .

2. For big equipment,like ,gas furnace ,bogie hearth furnace ,and large scale electric resistance ,we provide overseas installation and debugging services.

Related spare parts

Spare parts including :Loading basket,muffle,Kanthal heating element,radiant tube heater,loading rack ,Refactory insulation fiber,insulation bricks and so on.

Contacts

For more information ,please contact me by below contacts :