For second hand machine, it can not be customized, but we provide modification or upgrade services as your demands.

- Product Details

- {{item.text}}

Quick Details

-

Control System:

-

PLC, Servo Motor, Main Axis

-

Air Pressure:

-

0.6-0.8Mpa

-

Machine Color:

-

White, Blue, Green

-

Diaper Types:

-

I-shaped, T-shaped, Full waistband, Pull-up

-

Diaper Sizes:

-

NB, S, M, L, XL

-

Side Tape:

-

PP tape, S-cut tape

-

Back Sheet Film:

-

PE film, Lamination film

-

Machine Modified Service:

-

Acceptable

-

Product Name:

-

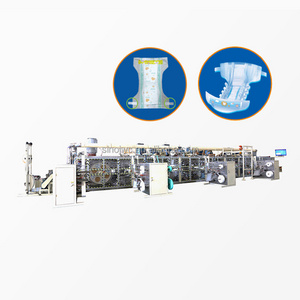

Used Baby Diaper Machine

Quick Details

-

Production Capacity:

-

≥97%

-

Place of Origin:

-

Fujian, China

-

Production Speed:

-

300~500pcs/minute

-

Control System:

-

PLC, Servo Motor, Main Axis

-

Air Pressure:

-

0.6-0.8Mpa

-

Machine Color:

-

White, Blue, Green

-

Diaper Types:

-

I-shaped, T-shaped, Full waistband, Pull-up

-

Diaper Sizes:

-

NB, S, M, L, XL

-

Side Tape:

-

PP tape, S-cut tape

-

Back Sheet Film:

-

PE film, Lamination film

-

Machine Modified Service:

-

Acceptable

-

Product Name:

-

Used Baby Diaper Machine

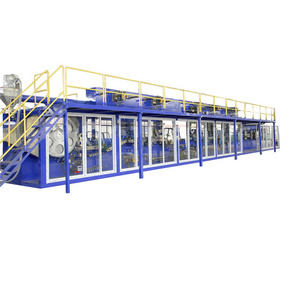

Semi Full Servo Automatic Second Hand Used Underpad Under Pad Sanitary Napkin Adult Baby Diaper Production Line Making Machine

Product Overviews

Product Description

Our website hereby lists some of the products we have successfuly supplied, please note that this constitutes just a tip of the iceberg of our products and services. If you fail to find the products you want, please feel free to contact us!

|

MAIN CONFIGURATION

|

|

|

|

|

||||

|

Program System

|

|

Servo driven, intelligent HMI touch screen man-machine interface

|

|

|

||||

|

Tension System

|

|

Tension control with buffer system, automatic web guiding system, to ensure materials stable working ar ZERO speed splice.

|

|

|

||||

|

Driven System

|

|

Servo drive, digital size change, ensure run synchronously at full process.

|

|

|

||||

|

Safety System

|

|

Safety guard for operating side, emergency stop switch, security identifier, safety pull wire at driven side.

|

|

|

||||

|

Packaging System

|

|

Auto stacker to be defined by customer need (dual push dual exit), the stacking range: 16-40pcs/pack adjustable.

|

|

|

||||

|

Web Guiding System

|

|

Germany BST/USA FIFE

|

|

|

||||

|

Product Detection System

|

|

Including the weight, metal, appearance, position

|

|

|

||||

|

Customization

|

|

Available

|

|

|

||||

|

I SHAPED BABY DIAPER PRODUCTION LINE

|

|

|

|

|

||||

|

MAIN PARAMETERS

|

|

|

|

|

||||

|

Working Speed (production speed)

|

|

600-800 pcs/minute

|

|

|

||||

|

Power Supply

|

|

380V 50/60HZ, Tri-phase

|

|

|

||||

|

Installation Power Capacity

|

|

220~330KW

|

|

|

||||

|

Air Consumption

|

|

4800l/minute

|

|

|

||||

|

Air Pressure

|

|

0.6-0.8Mpa

|

|

|

||||

|

Qualified Rate

|

|

≥98% (excluding scrap caused by hot melt, materials splicing or joint)

|

|

|

||||

|

Efficiency

|

|

≥85%

|

|

|

||||

|

Machine Weight

|

|

55 Tons approximately

|

|

|

||||

|

Machine Size (meters)

|

|

L: 25-30 W: 4.5-8 H: 3.5-4.5

|

|

|

||||

|

CONFIGURATION & OPTIONS

|

|

|

|

|

||||

|

Product Structure

|

|

Upper & lower tissue (or airlaid paper), cotton core (mix with SAP), ADL, PE film, frontal tape, topsheet hydrophilic nonwoven, leg cuff hydrophobic nonwoven, side tape, waistband

|

|

|

||||

|

Product Size

|

|

NB, S, M, L, XL

|

|

|

||||

|

Product Specification

|

|

Width: 280-340mm Length: 360-550mm

|

|

|

||||

|

T SHAPED ELASTIC EAR BABY DIAPER PRODUCTION LINE

|

|

|

|

|

||||

|

MAIN PARAMETERS

|

|

|

|

|

||||

|

Working Speed (production speed)

|

|

400-500 pcs/minute

|

|

|

||||

|

Power Supply

|

|

380V 50/60HZ, Tri-phase

|

|

|

||||

|

Installation Power Capacity

|

|

220-330KW

|

|

|

||||

|

Air Consumption

|

|

4800l/minute

|

|

|

||||

|

Air Pressure

|

|

0.6-0.8Mpa

|

|

|

||||

|

Qualified Rate

|

|

≥98% (excluding scrap caused by hot melt, materials splicing or joint)

|

|

|

||||

|

Efficiency

|

|

≥85%

|

|

|

||||

|

Machine Weight

|

|

55 Tons approximately

|

|

|

||||

|

Machine Size (meter)

|

|

L: 25-30 W:4.5-8 H:3.5-4.5

|

|

|

||||

|

CONFIGURATION & OPTIONS

|

|

|

|

|

||||

|

Product Structure

|

|

Upper & lower tissue, cotton core(mix with SAP), ADL, backsheet, frontal tape, topsheet hydrophilic nonwoven, leg cuff hydrophobic nonwoven, spunbond small ear, elastic big ear, waistband

|

|

|

||||

|

Product Size

|

|

NB, S, M, L, XL

|

|

|

||||

|

Product Specification

|

|

Width: 210-230mm Length: 360-550mm

|

|

|

||||

|

FULL ELASTIC WAISTBAND BABY DIAPER PRODUCTION LINE

|

|

|

|

|

||||

|

MAIN PARAMETERS

|

|

|

|

|

||||

|

Working Speed (production speed)

|

|

450-600 pcs/minute

|

|

|

||||

|

Power Supply

|

|

380V 50/60HZ, Tri-phase

|

|

|

||||

|

Installation Power Capacity

|

|

280-330KW

|

|

|

||||

|

Air Consumption

|

|

4800l/minute

|

|

|

||||

|

Air Pressure

|

|

0.6-0.8Mpa

|

|

|

||||

|

Qualified Rate

|

|

≥98% (excluding scrap caused by hot melt, materials splicing or joint)

|

|

|

||||

|

Efficiency

|

|

≥85%

|

|

|

||||

|

Machine Weight

|

|

70 Tons approximately

|

|

|

||||

|

Machine Size (meter)

|

|

L:25-30 W: 4.5-8 H:3.5-4.5

|

|

|

||||

|

CONFIGURATION & OPTIONS

|

|

|

|

|

||||

|

Product Structure

|

|

Upper & lower tissue (or airlaid paper), cotton core (mix with SAP), ADL, PE film, frontal tape, topsheet hydrophilic nonwoven, leg cuff hydrophobic nonwoven, side tape, waistband online

|

|

|

||||

|

Product Size

|

|

S, M, L, XL

|

|

|

||||

|

Product Specification

|

|

Width: 280-340mm Length: 360-550mm

|

|

|

||||

|

BABY PULL-UP DIAPER PRODUCTION LINE

|

|

|

|

|

||||

|

MAIN PARAMETERS

|

|

|

|

|

||||

|

Working Speed (production speed)

|

|

450-600pcs/minute

|

|

|

||||

|

Power Supply

|

|

380V 50/60HZ, Tri-phase

|

|

|

||||

|

Installation Power Capacity

|

|

380KW

|

|

|

||||

|

Air Consumption

|

|

1800-4800l/minute

|

|

|

||||

|

Air Pressure

|

|

0.6-0.8Mpa

|

|

|

||||

|

Qualified Rate

|

|

≥98% (excluding scrap caused by hot melt, materials splicing or joint)

|

|

|

||||

|

Efficiency

|

|

≥85%

|

|

|

||||

|

Machine Weight

|

|

85 Tons approximately

|

|

|

||||

|

Machine Size (meter)

|

|

L: 28-30 W: 6-12 H: 3.5-4.5

|

|

|

||||

|

CONFIGURATION & OPTIONS

|

|

|

|

|

||||

|

Product Structure

|

|

Upper & lower tissue (or airlaid paper), cotton core (mix with SAP), topsheet hydrophilic nonwoven, ADL, leak cuff hydrophobic nonwoven, 3D core coating, back sheet, waist nonwoven, printed cartoon tissue, waist elastic, s elastic, easy tape

|

|

|

||||

|

Product Size

|

|

M, L, XL, XXL

|

|

|

||||

|

Product Specification

|

|

Width: 385-420mm Length: 400-550mm

|

|

|

||||

Our Advantages

CNC Processing Ability & Strict Process:

We subcontract processing including turn-milling, five axis, and gantry CNC machining center are introduced from Mazak, Moirisiki and Tsugami in Japan which are the world's most advanced equipment. They realized the high speed, high efficiency, high quality spare parts processing capacity, and ensure equipment parts processing precision and reduce labor costs.

In accordance with the ISO9001 quality control system, we will strictly control the quality in every link and every process in the production. And all the equipment has to pass strict inspection before they leave the factory to ensure product efficient, high quality, high performance and stable production.

Professional Team

&

High Quality Supplier:

The equipment parts are all come from high quality suppliers. Electric appliances are world famous brands, which is the basis of reliable and stable equipment quality.

Moreover, we have a skillful and well-experienced professional team in household paper machinery manufacturing. The all have specialty in appointed iems to ensure the quipment precision machining and assembly accuracy

Application

Customized Solution

Hot Searches