- Product Details

- {{item.text}}

Quick Details

-

Power:

-

18kw, 36kw

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

customized

-

Name:

-

Vertical Pressure Steam Sterilizer

-

Material:

-

304 stainless steel vertical pressure steam sterilizer

-

Function:

-

Multifunctional vertical pressure steam sterilizer

-

Design pressure:

-

0.35Mpa, 0.44Mpa

-

Max Working Pressure:

-

0.3Mpa, 0.44Mpa

-

Max Temperature:

-

145℃

-

Control system:

-

Fully Automatic

-

Heating way:

-

Boiler Steam/Electric/Hot Water Heating

-

Sterilizing way:

-

Hot Steam Autoclave/High Temperature Water Spray

-

Application:

-

Food Products

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Orangemech

-

Voltage:

-

380v

-

Power:

-

18kw, 36kw

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

customized

-

Name:

-

Vertical Pressure Steam Sterilizer

-

Material:

-

304 stainless steel vertical pressure steam sterilizer

-

Function:

-

Multifunctional vertical pressure steam sterilizer

-

Design pressure:

-

0.35Mpa, 0.44Mpa

-

Max Working Pressure:

-

0.3Mpa, 0.44Mpa

-

Max Temperature:

-

145℃

-

Control system:

-

Fully Automatic

-

Heating way:

-

Boiler Steam/Electric/Hot Water Heating

-

Sterilizing way:

-

Hot Steam Autoclave/High Temperature Water Spray

-

Application:

-

Food Products

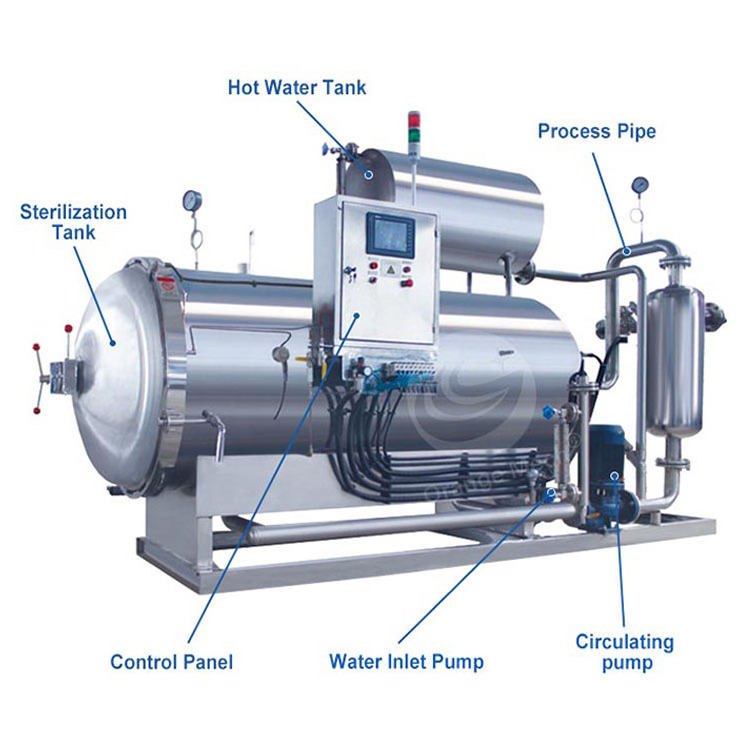

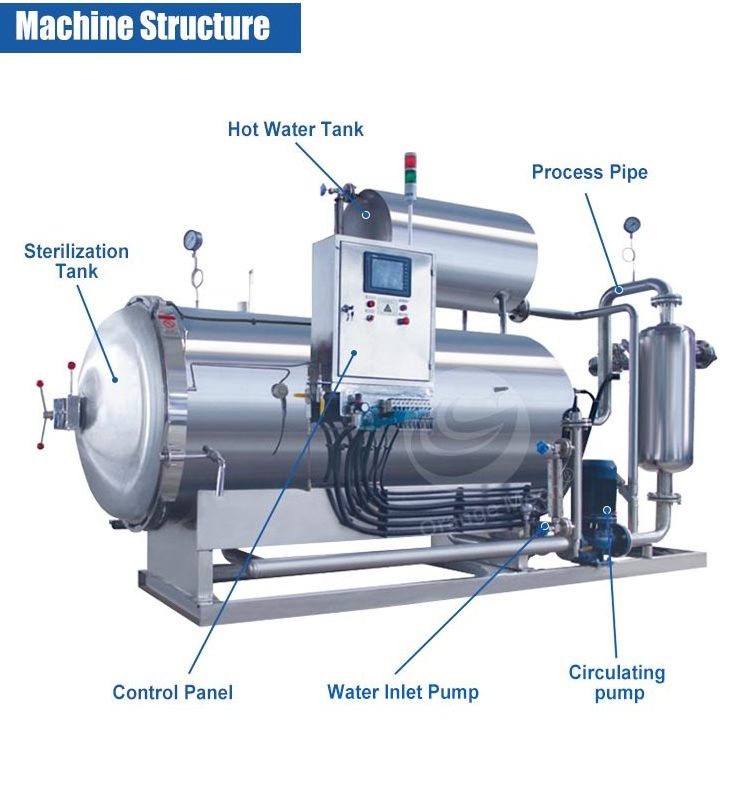

◆ Product Description

Introduction

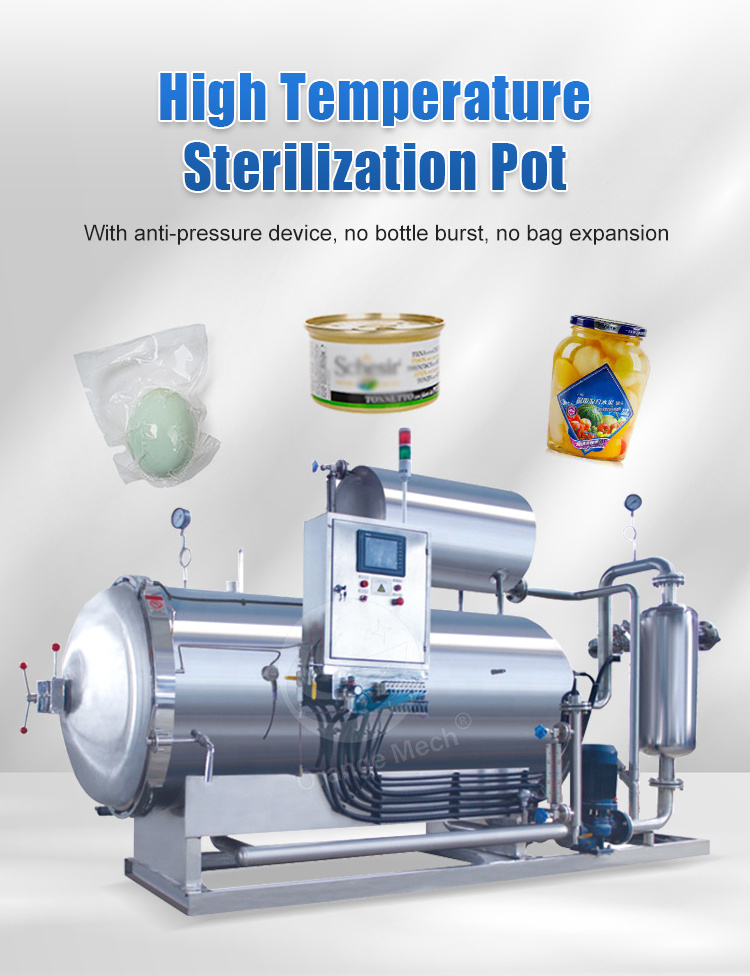

Sterilization kettle is a type of equipment that sterilizes cooked food through high pressure and high temperature.

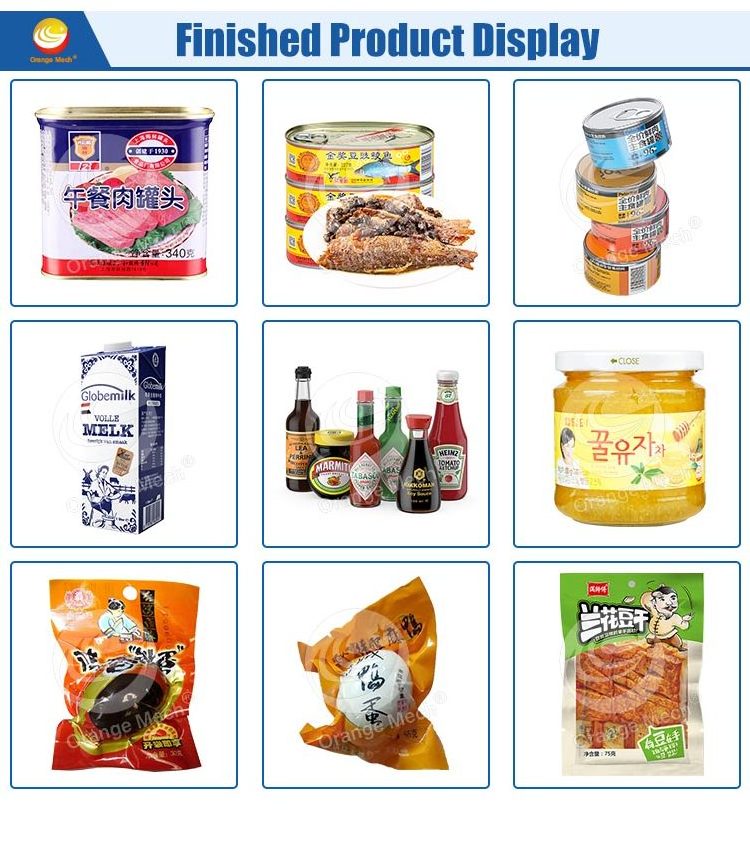

Application

The sterilizing pot mainly sterilizes food, canned foods, and foods that require high-temperature sterilization to extend the shelf life of the food.

Scope of application: Metal containers: tinplate cans, aluminum cans, plastic containers: PP bottles, HDPE bottles, soft bag packaging: aluminum foil bags, vacuum bags, high-temperature cooking bags, etc.

Feature

1.

Adopting the technology of "precise back pressure control in the pot" and the method of "wave-shaped hot water injection", the products in the pot can be fully and evenly pressed and heated.、

2.

Adopt the "real-time flow accurate measurement" device. Ensure that the product in the pot is evenly heated to avoid "cold spots".

3.

The sterilizer is equipped with PLC intelligent control and fully automatic touch screen, which is easy to operate.

4.

The cooling water is separated from the sterilizing water. It will not cause secondary pollution, and at the same time it can be recycled and save water.

5.

The sterilization pot is heated and sterilized in a short time, the flavor and taste of the produced food are almost unchanged, and the range of processed products is also wider.

|

Machine

|

High Temperature Sterilization Pot

|

|

|

||

|

Sterilization tank(below) Inner diameter*length

|

500 mm *800mm

|

700 mm*1200mm

|

900 mm*1800mm

|

||

|

Hot water tank (top)Inner diameter*length

|

500 mm*800mm

|

700 mm*1200mm

|

900 mm*1800mm

|

||

|

Design Pressure(Mpa)

|

0.35

|

0.44

|

0.44

|

||

|

Max Working Pressure(Mpa)

|

0.30

|

0.44

|

0.44

|

||

|

Max Working Temperature

|

145℃

|

|

|

||

|

Electric heating power

|

18kw*2

|

36kw*2

|

36kw*2

|

||

|

Sterilization tray

|

3pcs

|

3pcs

|

3-4pcs

|

||

|

Sterilization car

|

1

|

1

|

2

|

||

|

Voltage

|

380V

|

|

|

||

|

Material

|

SUS304

|

|

|

||

|

Water quality requirements

|

The sterilizing water and cooling water are tap water, the chloride ion content in the water is not higher than 25mg/L

|

|

|

||

◆ Product Details

◆ Product Photograph

◆ Packaging & Shipping

Hot Searches