- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

100m*100m*2.2m

-

Weight:

-

5500

-

Power (kW):

-

63KW

-

Applicable Industries:

-

Other

-

waste tire processing machinery:

-

used tire retreading

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SINOSTAR

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

100m*100m*2.2m

-

Weight:

-

5500

-

Power (kW):

-

63KW

-

Applicable Industries:

-

Other

-

waste tire processing machinery:

-

used tire retreading

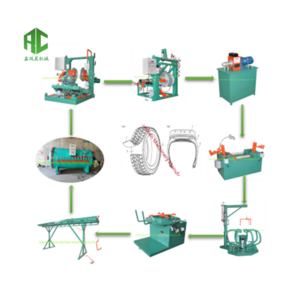

cold tire retreading machine/tire retreading line/TBR OTR tire retreading equipment/curing chamber

Initial Inspection Machine

Every single tire casing will receive a thorough inspection identifying potential defects.Using multiple methods to inspect tires for defects and ensure only high quality casings to be retreaded.If repairs are needed, they are administered after inspection.

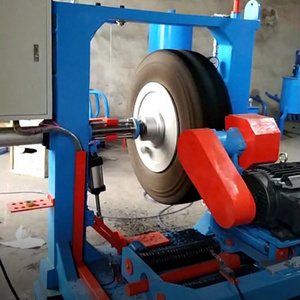

Buffing Machine

The tire’s old tread is mechanically removed on high speed buffers.Melion's buffers are extremely accurate and will remove the proper amount of old rubber while turning the tire to an exact specified diameter and radius.

Rubber Dust Collector

Collecting Rubber Crumbs which buffed off old tread by Buffing Machine

Multifunctional Repair Machine

With advances in state-of-the-art repair materials and repair methods, many of these tyres can be routinely repaired and in most cases can be retreaded when the original tread is worn off. The repair station is where any surface injury is treated using effective material and tools for grinding and patching.

Cement Mixing Tank

Engineered with explosion-proof motor,Cement Mixing Tank stir industrial solvent and rubber materials evenly to guarantee the procedure of cement spraying.

Tread Building Machine

In the Pre-cure Tire Retreading System, the Tread Rubber has already been vulcanized with the new tread pattern design. The buffed tire needs a thin layer of cushion gum to be wrapped around its crown area. The Pre-cured Tread Rubber(PTR) is then applied with the building machine. This is called Building Process.

Envelope Spreader

Operate the air cylinder and drive the Spreading Arms outwards to spread the Envelope. Then open the Gripper and grip the bead, and then lift the tire up with the cylinder-driven cable wire and guiding pulley. Rotate the lifting arm and lower the tire into the center of the Spreading Arms, and put it into the envelop. Manipulate the Air Cylinder to retrieve the Spreading Arms and release the Spreading Pads off the Envelop. Then lift the tire out of the Spreader.

Rim Mounting Machine

It's convenient to remove the curing rims. Pneumatic elevator, lift the tires easily

Monorail System

The monorail & hooks system increase productivity by reducing chances of casing contamination and allows for faster loading and unloading of tires.This increases your work place safety and productivity.

Curing Chamber

The Tires are then placed in Curing Chamber and the pre-cured tread becomes adhered to the tyre through a vulcanizing process.

Acording to buyers output we can supply different kinds of capacity tire retreading production line, all the machines can be customized.