Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

BERGEK

-

Brand Name:

-

OEM

-

Material:

-

Aluminum , stainless steel , Brass

-

Process:

-

Milling

-

Product name:

-

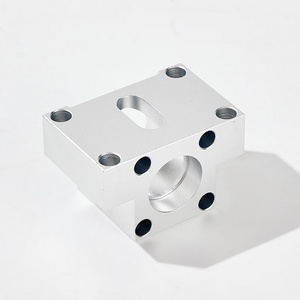

Customized cnc milling service parts cnc milling

-

Service:

-

Customized OEM

-

Keyword:

-

cnc milling service

-

Surface treatment:

-

Powder Coating , Anodizing

-

Name:

-

Customized Machined CNC Machining

-

Item:

-

CNC Precision Machining Part

-

Product Type:

-

cnc milling

-

Color:

-

Customized Color

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

BERGEK

-

Brand Name:

-

OEM

-

Material:

-

Aluminum , stainless steel , Brass

-

Process:

-

Milling

-

Product name:

-

Customized cnc milling service parts cnc milling

-

Service:

-

Customized OEM

-

Keyword:

-

cnc milling service

-

Surface treatment:

-

Powder Coating , Anodizing

-

Name:

-

Customized Machined CNC Machining

-

Item:

-

CNC Precision Machining Part

-

Product Type:

-

cnc milling

-

Color:

-

Customized Color

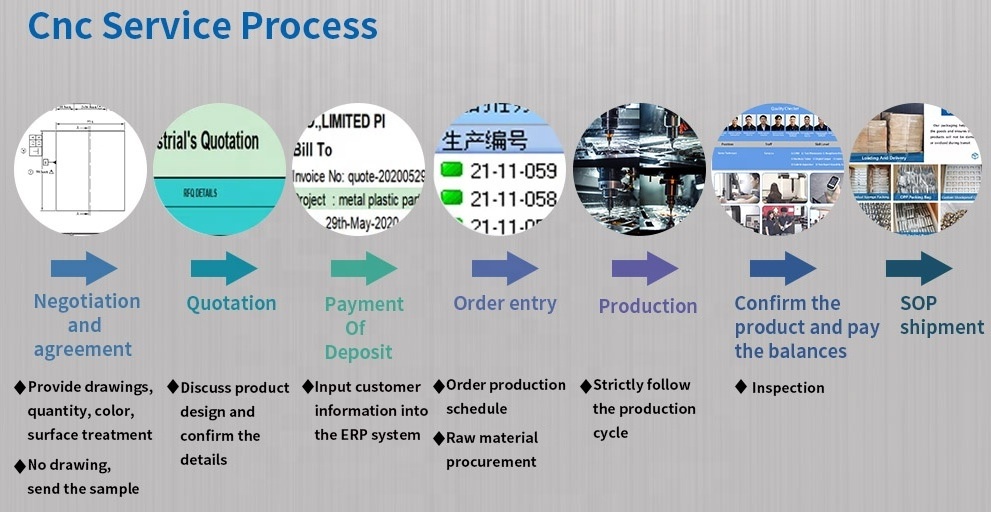

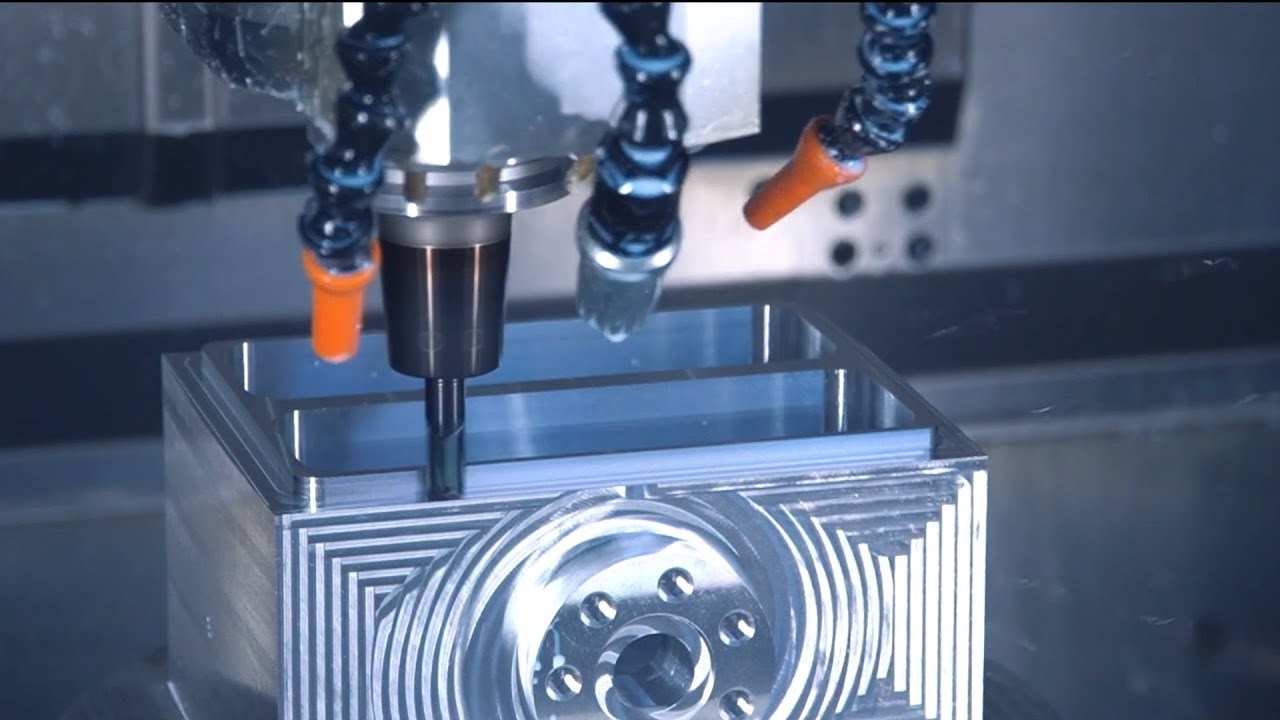

CNC Milling Processing

Our CNC milling services can produce highly accurate and complex parts from a variety of materials, including metals, plastics,and composites.

Machinery Axis: 3,4,5,6

Tolerance:+/- 0.01mm

Special Areas: +/-0.005mm

Surface Roughness: Ra 0.1~3.2

Supply Ability:300000Piece/Month

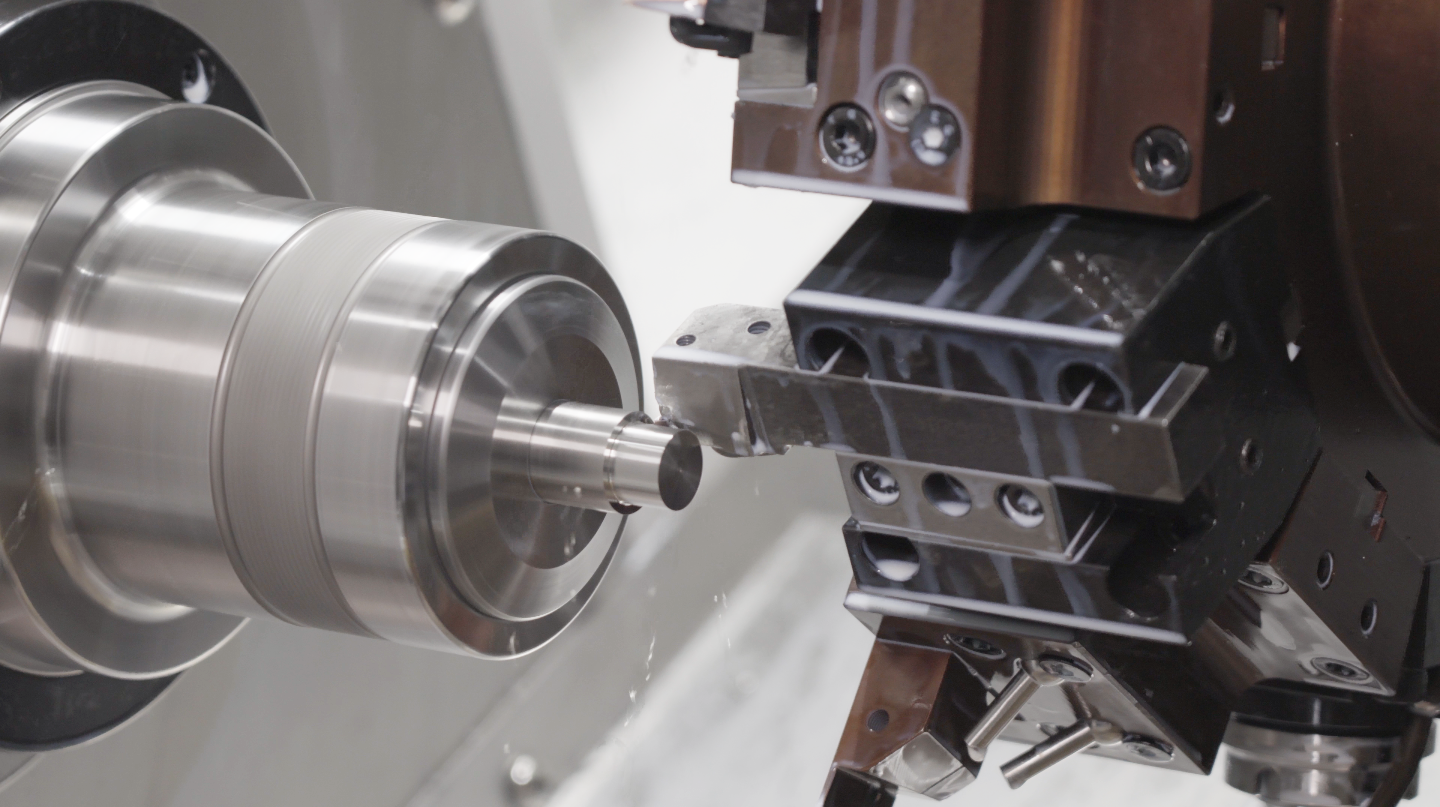

CNC Turning Processing

OEM&ODM

Customized Precision Parts

1-Piece minimum order

3-Hour quotation

Samples: 1-3 Days

Lead time: 7-14 Days

QC team, inspection

We are proud to hold several production certificates for our CNC machining services, which demonstrates our commitment to quality and customer satisfaction. Our team follows strict quality control procedures to ensure that every part we produce meets the highest standards of quality and accuracy.

Guaranteed quality based on the strict quality control system, fully implementing ISO9001: 2015

Quality is the true reason that BERGEK survive in the market for so many years. We saw many of our competitors are making money by playing around the quality and they lose the market faster than we think. We know that is not a sustainable business pattern.We are a professional supplier. we know what we are doing. We keep a very stable quality level for years. our qualified products rate is 99.86% and we are constantly improving it, thanks to our professional production team and technical team. We hope our clients can get what they paid for.

Wide range of surface finishes

|

Service

|

Precision custom CNC turning parts

|

|

|

|

||||

|

Tolerance

|

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form.

|

|

|

|

||||

|

MOQ

|

Low MOQ Start 1 Pcs ( No need mold cost ), Many Customers found us make prototype product to save Investment Funds for Pre-R&D and Market Testing.

|

|

|

|

||||

|

Sample Cost

|

Free of Sample Cost. Normally is USD 35~110 per Style Of Special Design We Need Sample Charge, Can Refund when You Have Official Bulk Order.

|

|

|

|

||||

|

Delivery Time

|

1-25 days after order with prepayment based on product structure and quantity.

|

|

|

|

||||

|

|

|

|

|

|||||

Product protection shield -- customized packaging

Protect the product and deliver it to you safely

FAQ

What parts can you buy from Bergek? CNC machining milling parts / turning parts, stamping parts, sheet metal fabrication parts, bending parts Why should you buy from Bergek not from other suppliers? Focused on CNC machining and sheet metal fabrication, Provide one-stop solution for CNC turning, CNC milling, stamping bending, and sheet metal manufacturing. Can Bergek make design drawings for me? We do not provide design services. You are responsible for submitting 2D and 3D CAD drawings, and we can then provide a Design for Manufacturing review upon receiving your order. send your drawing and start today How does Bergek compare to other suppliers on price? As compared to Chinese suppliers, we choose not to compete on price but to offer the highest levels of quality, rapid response, and professional results. and that’s why so many customers cooperate with us, Compared with the price, they need a reliable partner to avoid serious losses caused by annoying after-sales or even the trouble of finding no one. What tolerances can Bergek achieve? There is not a given set of tolerances that fits all processes and materials. In every case, the final tolerances on your part will depend on a number of factors, including but not limited to: Part size Design geometry The number, type, and size of features Material(s) Surface finish Manufacturing process Once your order is confirmed, we will review your design and provide a design for manufacturing review, pointing out any areas where we may not be able to achieve your desired tolerances. It’s helpful if you can specify which areas in your design have critical tolerances that must be met and which can be slightly modified if needed to reduce the time and costs involved. General Tolerances to DIN ISO 2768 for CNC machining in metal and plastic also as sheet metal parts All manufacturing and technical specifications need to be clearly specified in the 2D drawings in order to be followed. How does Bergek ensure the quality of my parts? Once your order is confirmed, we will perform a full Design for Manufacturing (DFM) review to point out any issues that our engineers feel may affect the quality of your parts. Each batch of goods must have first article assurance(FAA), and then IPQC inspections for many times, Final inspection reports before shipment. What type of material surface finishes does Bergek provide? We offer a wide variety of material and finishing services to achieve almost any look and feel on your parts. We offer treatments for metal as bellow .

1,M

aterial

|

Stainless Steel

|

SS201,SS301,SS303, SS304, SS316, SS416 etc.

|

|

|

|

|||

|

Steel

|

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc.

|

|

|

|

|||

|

Brass

|

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc.

|

|

|

|

|||

|

Copper

|

C11000,C12000,C12000, C36000 etc.

|

|

|

|

|||

|

Aluminum

|

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc.

|

|

|

|

|||

|

Iron

|

A36, 45#, 1213, 12L14, 1215 etc.

|

|

|

|

|||

|

Plastic

|

ABS, PC, PE, POM, Nylon, PP, Peek etc.

|

|

|

|

|||

2, Surface Treatment

|

Stainless Steel

|

Polishing, Passivating, Sandblasting, Laser engraving

|

|

Steel

|

Zinc plating, Oxide black, Nickel plating, Chrome platingk, Carburized, Powder Coated

|

|

Aluminum parts

|

Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing

|

|

Plastic

|

Plating gold (ABS), Painting, Brushing (Acylic), laser engraving

|

What if I am not completely satisfied with the parts I receive?

We guarantee our materials and workmanship based on the terms of the initial order and the information provided by you. Any disputes based on a subjective determination shall be brought to the attention of management who will act in good faith to provide you with complete satisfaction. Our continuing business relies on earning your confidence in our ability to meet and exceed any reasonable expectations.

Hot Searches