- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1300*900*1480

-

Power (kW):

-

3 kW

-

Weight (KG):

-

180 KG

-

Applicable Industries:

-

PYROLYSIS PLANT

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Brand:

-

Doing

-

Machine Type:

-

QKF850

-

Power:

-

2.2KW~3 KW

-

Processing range(mm):

-

900~1200

-

Production:

-

40~60pieces/hour

-

Dimension (D*L) of Reactor:

-

1300*900*1480

-

Name:

-

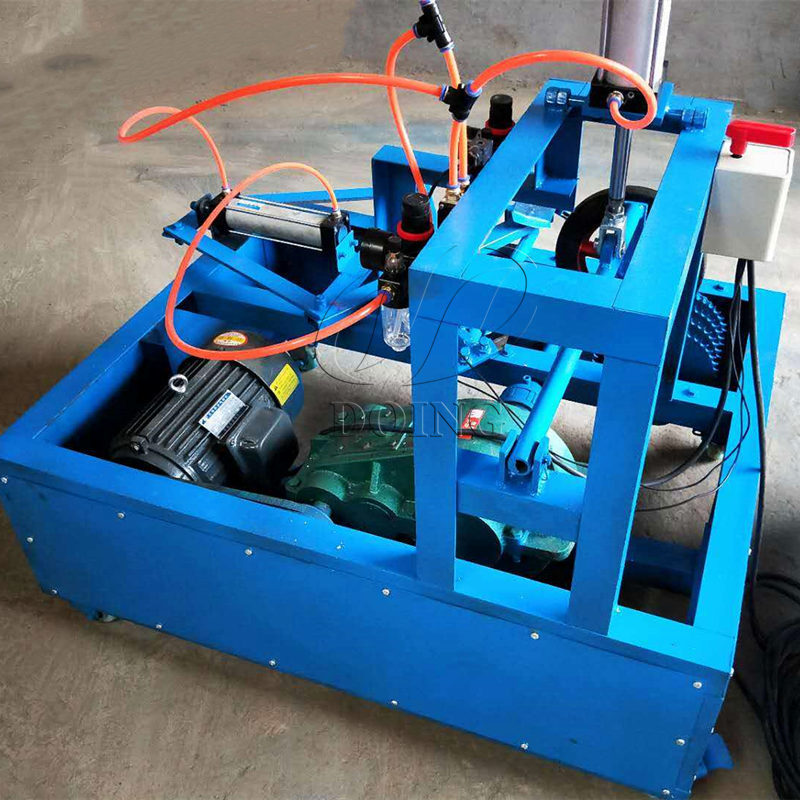

Used tire debeader machine for pirolisis tyre side wall cutter

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DOING

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

1300*900*1480

-

Power (kW):

-

3 kW

-

Weight (KG):

-

180 KG

-

Applicable Industries:

-

PYROLYSIS PLANT

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Brand:

-

Doing

-

Machine Type:

-

QKF850

-

Power:

-

2.2KW~3 KW

-

Processing range(mm):

-

900~1200

-

Production:

-

40~60pieces/hour

-

Dimension (D*L) of Reactor:

-

1300*900*1480

-

Name:

-

Used tire debeader machine for pirolisis tyre side wall cutter

Why we developed Waste tire sidewall cutter tire cutting machine?

With the rapid development of the worlUsed tire debeader machine for pirolisis tyre side wall cutterd automobile industry and transportation industry, the demand of all kinds of tires are increasing day by day. At present, more than billions of tires are sold all over the world every year. According to the research, 50-55% raw rubber are used for the tire manufacturing every year. For security, automobiles should change tires after every 30,000-50,000 km trip distance. In this way, billions of waste tires, about 17 millions tons can be produced in one year. And waste tires is a kind of non-fusible or refractory polymer elastomer materisl, which will take hundreds of years to decompose. With the time goes, the waste tire problem has become serious to environment. How to dispose the waste tires also become more and more important in every countries.

Because of this, except the tire pyrolysis machine, the rubber powder production line is another new develop and design equipment used for recycling waste tires to rubber pwder for recycle use.

Used tire debeader machine for pirolisis tyre side wall cutter

Used tire debeader machine for pirolisis tyre side wall cutter is used to separate the tire side from the tire body. Now the steel wire inside the tire sides of vacuum tires is very strong and hard to bend and cut. To save place for storage or convenient transport, it's better to cut the tire sides from the tire body. And the steel wire inside the tire ring also can be separated by a tire steel wire separator for further process or recycle use.

|

Technical Parameters of Used tire debeader machine for pirolisis tyre side wall cutter

|

|

|

Motor Power |

3kw |

|

Capacity(kg/h) |

300-500kg/h |

|

Rotation speed |

15r/min |

|

Dimension |

1200*1400*1300 |

|

Weight |

600kg |

|

Tire processing size |

650-1200mm |

Packaging & Shipping for Used tire debeader machine for pirolisis tyre side wall cutter

All the goods exported are packed in wooden case or carton with export standard except naked package when necessary. We have our own professional shipping company which could deliver the goods to every corner in the world with safety and speed, and also can supply the services of solving the problems occurred.

DOING best services for Used tire debeader machine for pirolisis tyre side wall cutter

1. Pre-sale services

Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investment

(1) Select equipment model;

(2) Design and manufacture products according to clients’ special requirement;

(3) Train technical personnel for clients.

2. On-sale services

Respect clients; devote ourselves to improving the total value of clients.

(1) Pre-check and accept products ahead of delivery;

(2) Help clients to draft solving plans.

3. After-sale services

Provide considerate services to minimize clients’ worries.

(1) Assist clients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

(4) Examine the equipment regularly;

(5)Take initiative to eliminate the troubles rapidly at site;

(6) Distribute the guarantee fittings door-to-door;

(7) Provide perfect service;