- Product Details

- {{item.text}}

Quick Details

-

Rated Rotation Speed:

-

10 RPM

-

Power of Main Motor:

-

250 kW

-

Copper Rod:

-

Copper Rod

-

Diameter Tolerance:

-

±0.2mm

-

Minimum Dimension:

-

Length: 30m, Width: 8m, Height: 8m

-

Flash Amount:

-

3-6%

-

Average Output:

-

1100kg /h

-

Standard:

-

Conforms to GB5585.1-85 standard

-

Max. Width:

-

170mm (or 20-70mm Copper Bar)

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

dayuan

-

Nominal Diameter of Extrusion Wheel:

-

400mm

-

Rated Rotation Speed:

-

10 RPM

-

Power of Main Motor:

-

250 kW

-

Copper Rod:

-

Copper Rod

-

Diameter Tolerance:

-

±0.2mm

-

Minimum Dimension:

-

Length: 30m, Width: 8m, Height: 8m

-

Flash Amount:

-

3-6%

-

Average Output:

-

1100kg /h

-

Standard:

-

Conforms to GB5585.1-85 standard

-

Max. Width:

-

170mm (or 20-70mm Copper Bar)

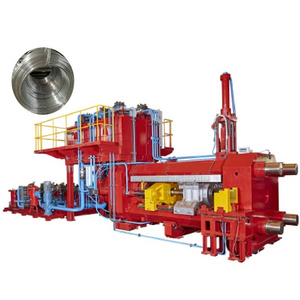

| Copper Continuous Extrusion Machine | ||

| Main Functional Unit: Continuous Extrusion Machine | Model | 400 |

| Nominal Diameter of Extrusion Wheel | 400mm | |

| Rated Rotation Speed | 10 RPM | |

| Power of Main Motor | 250 kW | |

| Feed Stock | Copper Rod | Copper Rod |

| Diameter Tolerance | ±0.2mm | |

| Yield Strength | 160MPa (Oxygen-free Copper Rod Produced by Upward Casting Process | |

| Copper Busbar | ||

| Finish Product : Flat Copper Wires | Sectional Area Range | 150-4500mm² |

| Max. Width | 170mm (or 20-70mm Copper Bar) | |

| Standard | Conforms to GB5585.1-85 standard | |

| Entire Production Line: Copper Wire Production Line | Average Output | 1100kg /h |

| Installed Capacity | 380V, 3 phase, 315KVA | |

| Flash Amount | 3-6% | |

| Workshop | Minimum Dimension | Length: 30m, Width: 8m, Height: 8m |

| Cooling Water | 80 m³/h (Cooling Tower) | |

| Compressed Air | 0.7 MPa, 1 m³/min | |

Main features

1, The continuous extrusion equipment is to extrude the copper rod to generate high pressure and high temperature.

Through mold extrusion forming, it can adapt to small-batch production of various kinds, and can also adapt to large-batch production.

2, Through the high-pressure and high-temperature treatment, the influence of defects (cracks, burr and so on) existing in the raw material on the finished products can be eliminated.

3, To increase the density.

The finished products are extruded at high temperature and high pressure, so that the surface is bright and clean, and the dimensional precision is high.

4, The product does not require annealing, and the hardness shall be uniform.

The extrusion process can thoroughly eliminate the problem of raw material joint, and the length of the required product is not subject to the restriction of the length of the raw material.

5, The floor area of the extrusion equipment is small, the installation and construction are simple, the energy consumption is low, and the labor intensity is low.

The safety during the production process is high, and the production environment is clean, which completely meets the environmental protection requirements.

Copper continuous extruder hot models: cs650 copper continuous extruder, cs300 copper continuous extruder, cs350 copper continuous extruder, cs400 copper continuous extruder, cs550 copper continuous extruder

|

|

Continuous extruder has a variety of models, divided into copper extruder and aluminum extruder and brass extruder, at the same time, we sell a variety of extruder parts

1. What brand of electrical appliances do you use? Can we specify a brand?

In the electrical part, we mostly use Schneider and Siemens, and can accept the brand designated by customers

2. What service can you supply?

Engineers available to service machinery overseas.

3. What’s the packages?

The normal package is wooden box. If export to foreign countries,the wooden box will be fumigated or use polywood case.

4. Can you do turn-key project?

Yes, We have a mature technical team that can do turnkey engineering.

5. What’s the payment terms?

30% by TT as deposit, 70% by TT or LC at sight vefore delivery.

6. What’s your advantages?

As a member of the family business, we have a copper production plant. Therefore, we are more familiar with the production process. At the same time, we have professional engineers and can get more direct use feedback. We have a good cooperative relationship with most of the domestic machinery manufacturers, so we can get a better price.

7. What’s the delivery time?

Usually 60 working days.