2.Competative price to save cost for customer

3.Good after-sale serive,we'll provide techical support for a long period

4.Rich experience for export mould

5.Dunctual delivery to produce products in time for customer

|

Name

|

Description

|

|

Mould material

|

p20,H13, 718,2738,2316 etc.

|

|

Mould base

|

Yuanda customaized

|

|

Cavity

|

Single

|

|

Runner

|

Hot/cold runner

|

|

Design software

|

UG ,PRC ,CAD,CAXA,etc.

|

|

Plastic material

|

Pure or recycle pp

|

|

Mould life

|

600000-3000000

|

|

Delivery time

|

40-85days

|

|

Specification

|

Depends on customer's requirments

|

|

1.R&D

|

Customer sends us sample or drawings,we do modification as per customer asked,

Some professional suggestion to help customer inprove the product details |

|

2.Negotiation

|

The options of steel,delivery time,payment,item,ect.

|

|

3.place and order

|

Customer confirms the plastic material,machine spec.special requirment on details,

We stard the drawings. |

|

4.Mould design

|

We mould design on the basis of confirmed product design,

accordingly,customer machine spec.and requirments to make mold design |

|

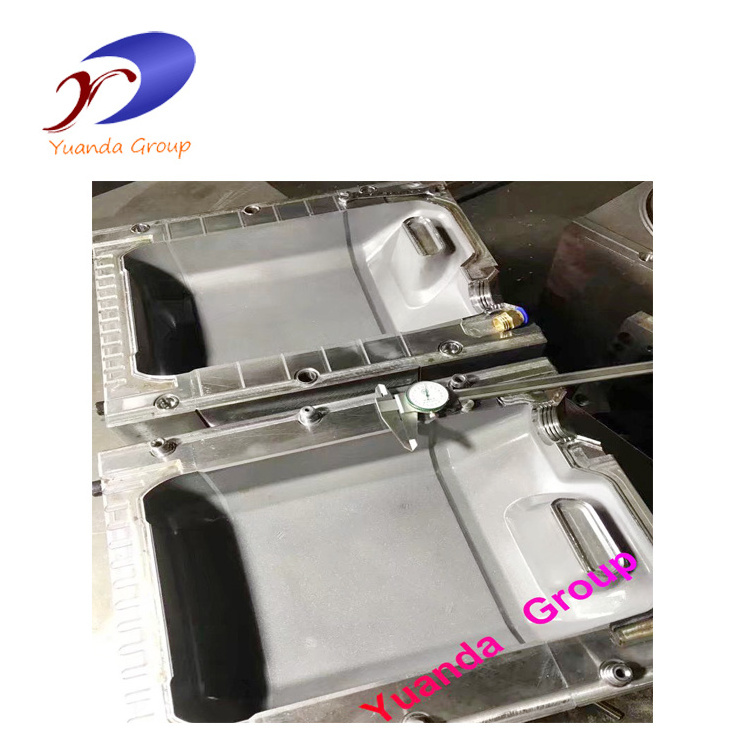

5.Mould tooling

|

We stard to make mould affer mould design confirmed,Cut steel,CNC machine,

Polishing ,sampling. |

|

6.Mould processing

|

Mould processing photos update to customers each week

|

|

7.Sample shoot

|

T0-T1;Checking if mould running corrects,the weight, wall thickness,dimension.

If meet customer request,if all ok ,arrange samples to customer approve. |

|

8.Delivery time

|

Once samples approved, we will ship the moulds in 7 days after customer shipping

|

|

9.Shiping

|

By sea/By air,Nearest port -Ningbo /Shanghai,Nearest airport Shanghai/Guangzhou.

|