- Product Details

- {{item.text}}

Quick Details

-

Grade:

-

TP316L S32205 n08825 n04400 n06625

-

Surface Finish:

-

BA

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MTSCO

-

Model Number:

-

MTALI29

-

Application:

-

down well

-

Outer Diameter:

-

6.35mm

-

Encapsulation Size:

-

33 x 11mm

-

Length:

-

PER FT

-

Casing drift:

-

N/A

-

Temp Rating:

-

325 deg F, It depends on the working environment

-

Pressure Rating:

-

15000 Psi, It depends on the working environment

-

Additional Material Specs:

-

ETFE, FEP, HDPE, PFA, PP, PVDF, TPV, PA11

-

Additional Features:

-

Color-coded, Fluid filling, oil filling

-

Certification:

-

Sgs

Quick Details

-

Type:

-

Seamless

-

Steel Grade:

-

316L

-

Tolerance:

-

±10%

-

Grade:

-

TP316L S32205 n08825 n04400 n06625

-

Surface Finish:

-

BA

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MTSCO

-

Model Number:

-

MTALI29

-

Application:

-

down well

-

Outer Diameter:

-

6.35mm

-

Encapsulation Size:

-

33 x 11mm

-

Length:

-

PER FT

-

Casing drift:

-

N/A

-

Temp Rating:

-

325 deg F, It depends on the working environment

-

Pressure Rating:

-

15000 Psi, It depends on the working environment

-

Additional Material Specs:

-

ETFE, FEP, HDPE, PFA, PP, PVDF, TPV, PA11

-

Additional Features:

-

Color-coded, Fluid filling, oil filling

-

Certification:

-

Sgs

MTSCO

Products Description

Main material: TP316L S32205 n08825 n04400 n06625

main outer diameters: 1/4" or 0.25", 3/8" or 0.375",1/2" or 0.50"

Wall thickness: 0.035", 0.049", 0.065"

Size : 3lines x 1/4" 0.049WT,

Encapsulation Size : 33 x 11mm,

Length : PER FT,

Casing drift : N/A,

Type : HYDRAULIC FLAT PACK,

Application : down well

Temp Rating: 325 deg F, It depends on the working environment

Pressure Rating: 15000 Psi, It depends on the working environment

Material: Inc 725,

Additional Material Specs: ETFE, FEP, HDPE, PFA, PP, PVDF, TPV, PA11

Additional Features: Color-coded, Fluid filling, oil filling

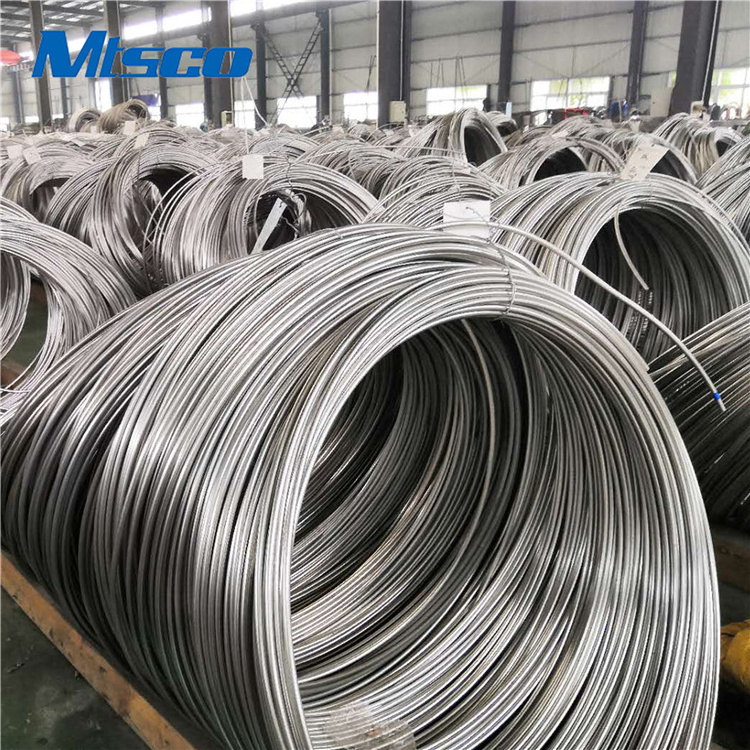

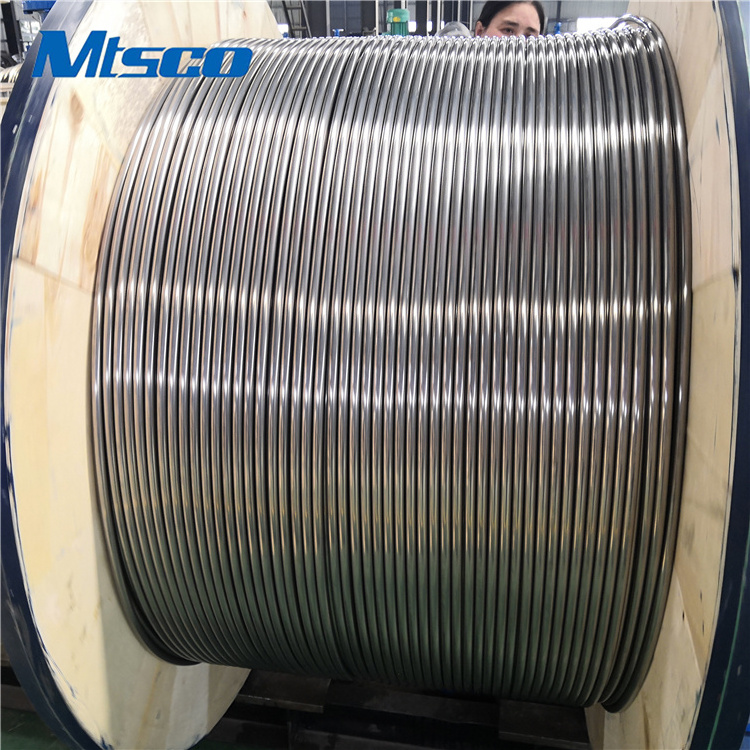

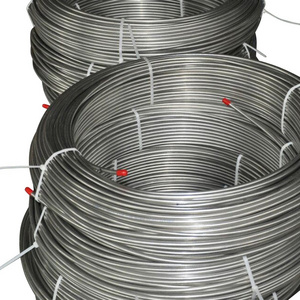

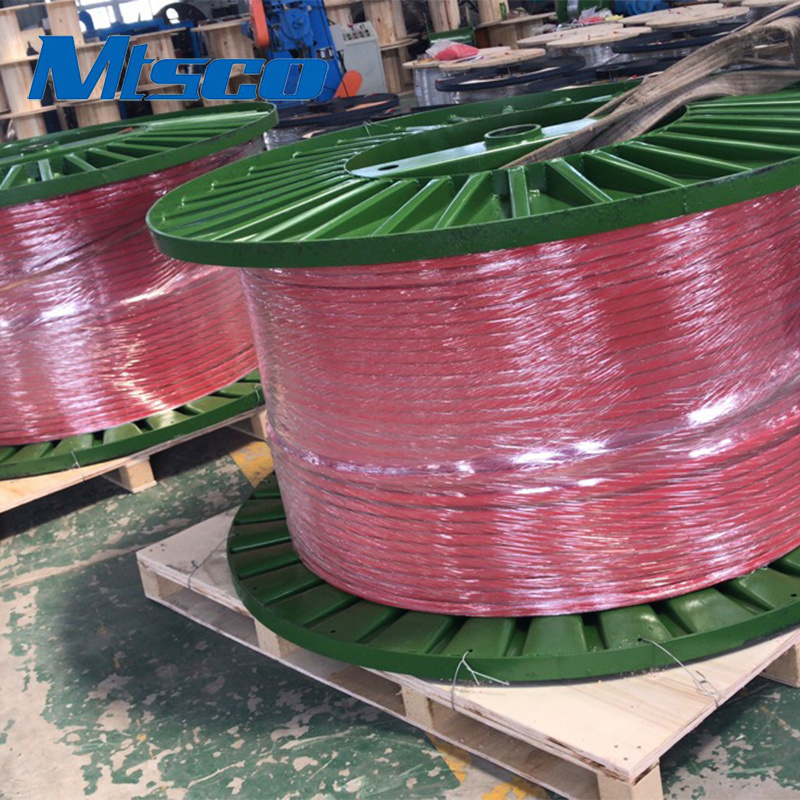

316L Coiled Tube

Coiled tubing are usually made of stainless steel, duplex stainless steel or nickel alloy, including stainless steel 316L, duplex 2205 and 2507, nickel alloy 825 and alloy 625.

The coiled tubes can be welded & redrawn tubes or seamless cold drawn tubes.

The coiled tubings are has very long continuous lengths coil, coiled tubing usually packed on coil wound on wooden drum or spool, also specific metal reels, Encapsulated and PVC coated are available.

|

C %

|

Si %

|

Mn %

|

P %

|

S %

|

Cr %

|

Ni %

|

Mo %

|

N %

|

Cu %

|

|

0.03 max

|

0.8 max

|

1.2 max

|

0.035 max

|

0.02 max

|

24.0-26.0

|

6.0-8.0

|

3.0-5.0

|

0.24-0.32

|

0.50 max

|

Advantage of 316L Coiled Tubing

High precision

High temperature resistance

Abrasion resistance

High Strength

Pressure resistance

Excellent electromagnetic

Shielding performance

Custom fabrication

Deeply process available

Application of 316L Coiled Tubing

Down hole tubes

General control system

Steam supply lines

Gas transport lines

Medical device industry

Industrial temperature control, sensors used pipe, tube thermometer

Pens care industry core tube

Laser engraving equipment

|

Description

|

|

28 x 11mm / L:15000feet

|

|

TPV/Encapsulation

|

|

3 Lines

|

|

|

General

|

|

|

||

|

Cleanliness-Control fluid

|

Empty

|

|

|

||

|

Identification

|

MTSCO / STANDARD / GRADE / SIZE / LENGTH / HEAT NO.

|

|

|

||

|

Material certification

|

MTC, Hydro test report

|

|

|

||

|

Reel

|

According to the customer's request

|

|

|

||

|

Reel's Holes

|

According to the customer's request

|

|

|

||

|

Total Weight (kg)

|

According to the length

|

|

|

||

|

|

|

|

|

||

|

|

Technical details

|

|

|

||

|

|

line 1

|

line 2

|

line 3

|

||

|

Outside diameter (in)

|

1/4"

|

1/4"

|

1/4"

|

||

|

Wall thickness (in)

|

0.049"

|

0.049"

|

0.035"

|

||

|

Color coding

|

According to the customer's request

|

|

|

||

|

Flush and Filling

|

Oil filling

|

Oil filling

|

No filling

|

||

|

Manufacturing specification

|

ASTM B704

|

ASTM B704

|

ASTM B704

|

||

|

Yield strength (psi)

|

≥34954

|

≥34954

|

≥34954

|

||

|

Test Pressure (psi)

|

5000

|

5000

|

5000

|

||

|

Maximum Hardness (HB)

|

85-90HRb

|

85-90HRb

|

85-90HRb

|

||

|

Tolerance: WT(%) OD (mm)

|

WT ±5% OD±0.003

|

WT ±5% OD±0.003

|

WT ±5% OD±0.003

|

||

Certifications

Hot Searches