High closed-cell rate, good water-proof

Good thermal insulation

High compressive strength

Close Cell Polyurethane pu rigid foam

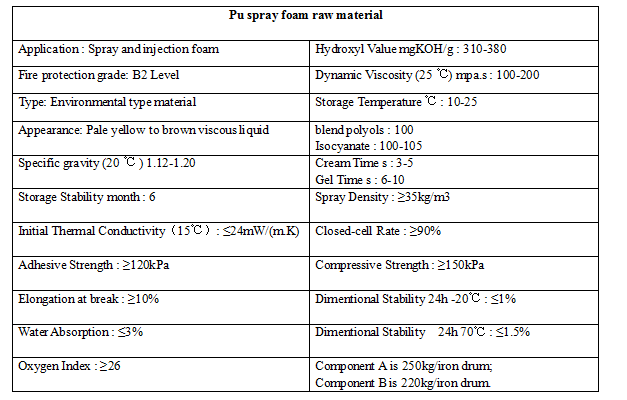

The product is a mixture consisting of polyether polyols, silicone stabilizer, flame retardant and catalys. It is a light yellow liquid at room temperature. It has been developed to produce B1 class fireproof outer wall spraying thermal insulation polyurethane foam in conjunction with polymeric MDI.

MDI polyurethane pu rigid foam

DMJ series polyol is a fully formulated polyol blend developed for spray application of polyurethane rigid foam. The component ratio of has been adjusted to make it suitable for polyurethane foam spraying machine using with a fixed volumetric component ratio of 1-1.2 : 1.

MDI polyurethane pu rigid foam

It already contains sufficient quantity of blowing agent HCFC 141b to achieve the foreseen foam density.

High closed-cell rate, good water-proof

Good thermal insulation

High compressive strength

Close Cell Polyurethane pu rigid foam

Component A: polyol

Component B: isocyanate

Close Cell Polyurethane pu rigid foam

When polyol and isocyanate (mdi) are mixed together using suitable foam spray equipment, the resulting foam has a homogenous density. Foams which are allowed to cure for a sufficient time between the layers applied have good skin formation and show good adhesion to the sprayed surface. Special care must be taken the sprayed surfaces are not cold or wet. It is mainly used for the insulation of wall&roof and cold room & container.

Component A is 220kg/iron drum;

Component B is 250kg/iron drum.

One set: 470 kg=220kg A+250kg B

One 20' container loads 40 sets/80 drums/18.8 tons

Close Cell Polyurethane pu rigid foam

price 4000USD

Polyols MDI pu foam spray material

price 2800USD