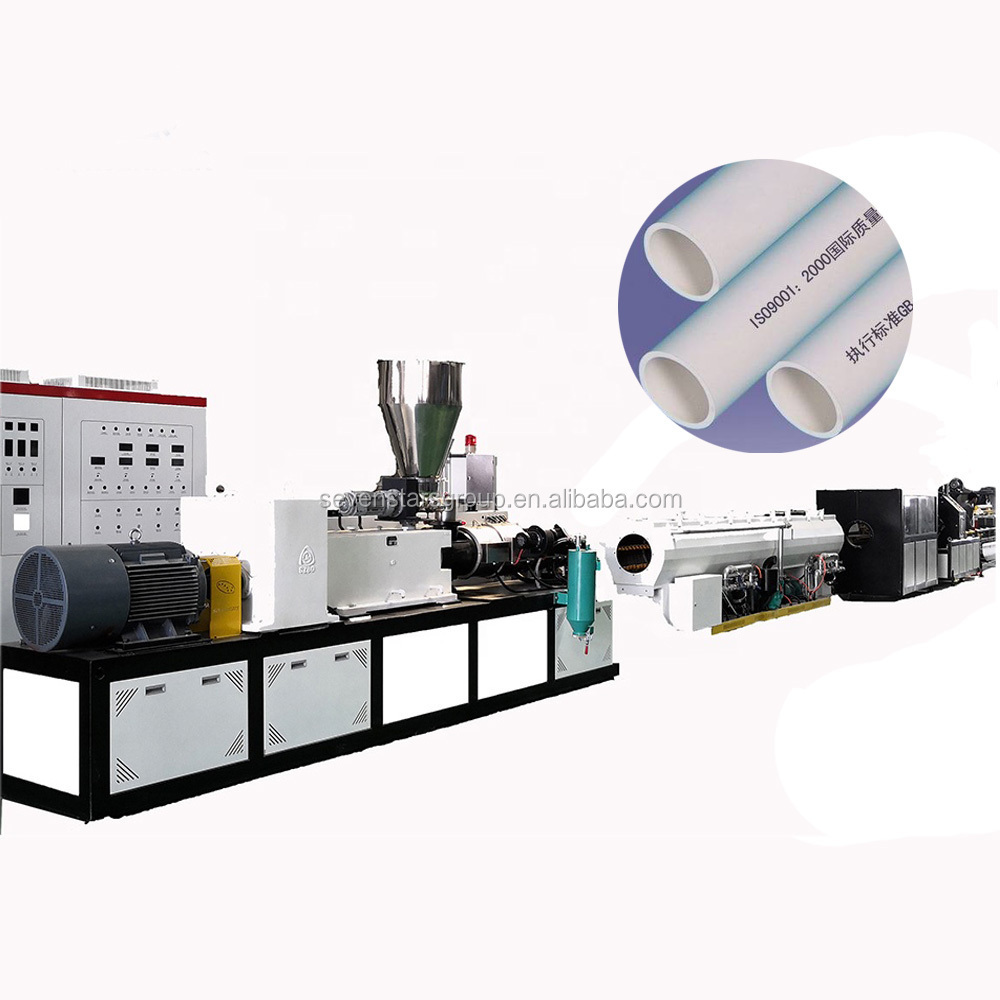

Conical double screw extruder

Technical parameter

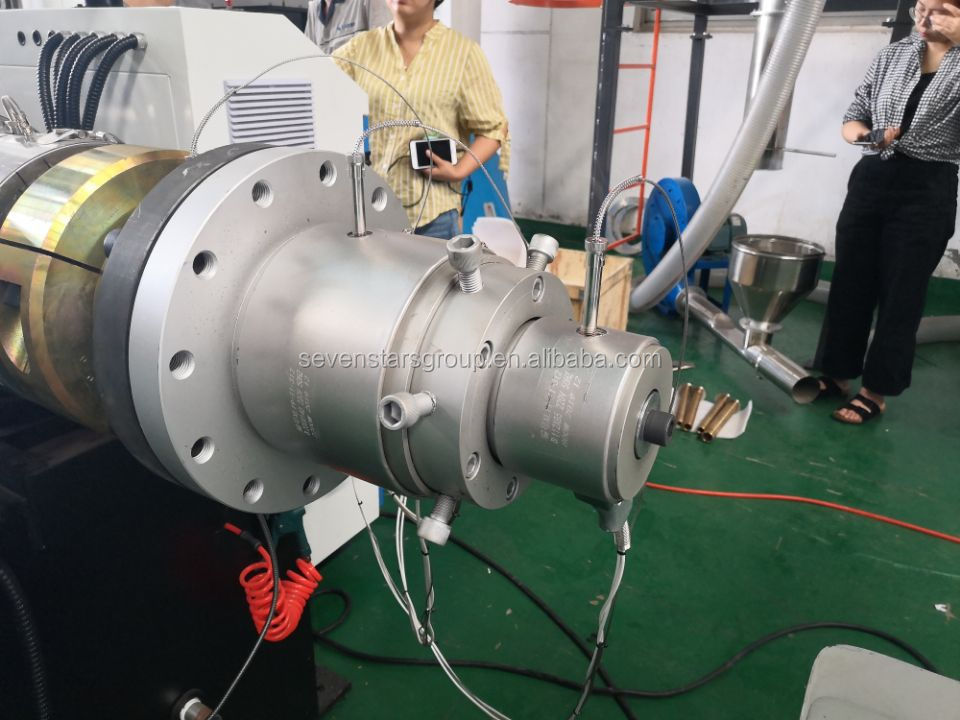

Material of screw: 38CrMoAl

Heating zones: 4 Heating power: 35kw

Cooling mode: Air fans

Driving motor: 55KW (siemens) Dosing feeding motor: 1.5KW Vacuum pump: 1 set

Cool mode: Air fans: 3 Sets