- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Uyoung

-

Year:

-

Hot sale

-

Voltage:

-

Customized to customer needs

-

Hollow part volume:

-

10-50L

-

Screw L/D Ratio:

-

28

-

Screw diameter (mm):

-

125 mm

-

Screw Heating Power(kW):

-

40 kW

-

Extruder Motor Power(kW):

-

110 kW

-

Mold Platen Size(Width)(mm):

-

900 mm

-

Mold Platen Size(Height)(mm):

-

950 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

0.1 m³/min

-

Die Head Heating Power(kW):

-

13 kW

-

Accumulator Capacity(L):

-

7 L

-

Power (kW):

-

185

-

Weight (T):

-

20

-

Certification:

-

CE IS09001

-

Color:

-

customized

-

Parison Control:

-

MOOG

-

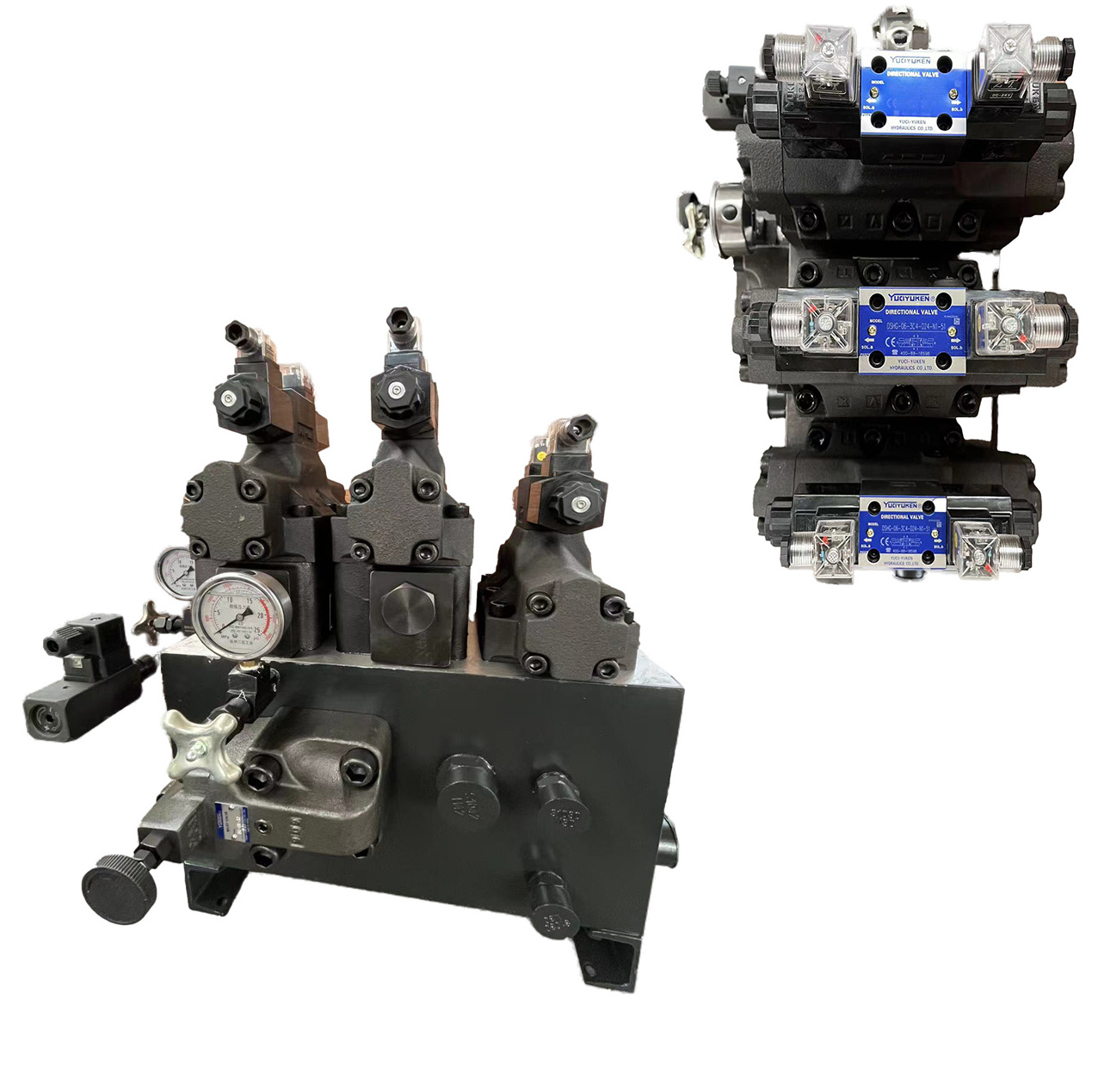

Valve:

-

YUKEN

-

Parison controller:

-

MOOG

-

Inverter:

-

ABB/SIMENS

-

After-sales Service Provided:

-

Online support,Engineers available to service machinery overseas

-

Key words:

-

Automatic Extrusion Blow Moulding Machine

-

Advantages:

-

20 Years Experiences

-

After Warranty Service:

-

Life

Quick Details

-

Clamping Force (kN):

-

400

-

Output (kg/h):

-

300 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Uyoung

-

Year:

-

Hot sale

-

Voltage:

-

Customized to customer needs

-

Hollow part volume:

-

10-50L

-

Screw L/D Ratio:

-

28

-

Screw diameter (mm):

-

125 mm

-

Screw Heating Power(kW):

-

40 kW

-

Extruder Motor Power(kW):

-

110 kW

-

Mold Platen Size(Width)(mm):

-

900 mm

-

Mold Platen Size(Height)(mm):

-

950 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

0.1 m³/min

-

Die Head Heating Power(kW):

-

13 kW

-

Accumulator Capacity(L):

-

7 L

-

Power (kW):

-

185

-

Weight (T):

-

20

-

Certification:

-

CE IS09001

-

Color:

-

customized

-

Parison Control:

-

MOOG

-

Valve:

-

YUKEN

-

Parison controller:

-

MOOG

-

Inverter:

-

ABB/SIMENS

-

After-sales Service Provided:

-

Online support,Engineers available to service machinery overseas

-

Key words:

-

Automatic Extrusion Blow Moulding Machine

-

Advantages:

-

20 Years Experiences

-

After Warranty Service:

-

Life

Products Description

Machine Overview

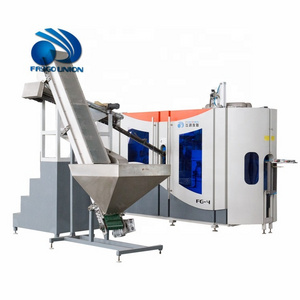

Fully Automatic tank,drum and bucket Blow Molding Machine to produce Jerry cans,oil bucket,painting buckets,

products can be designed into from 1 layer to multi layers.As clients' request,this machine can be designed to produce other blow molded plastic products which within size and weight limit.

Product Paramenters

|

Plasticizing capacity

|

300 Kg/H

|

|

Clamping Force

|

400KN

|

|

Screw Dia

|

125mm

|

|

Screw heating power

|

40kw

|

|

Accumulator capacity

|

5 kg

|

|

Die head heating power

|

13 kw

|

|

Auto feeder

|

Vacuum loader 3 kw

|

|

Main oil pump motor

|

30 kw Servo type

|

|

Main oil pump

|

Gear pump

|

|

Main parts brand

|

|

|

||

|

Motor

|

Siemens(Not BEIDE)

|

Germany

|

||

|

Inverter

|

Siemens/ABB

|

Germany

|

||

|

Touch screen/PLC

|

Siemens

|

Germany

|

||

|

Thickness controller/Servo valve

|

MOOG

|

Japan

|

||

|

Oil pump/valve

|

YUKEN

|

Japan

|

||

|

Gear box

|

Guomao/SEW

|

China/Germany

|

||

|

Low-voltage apparatus

|

Schneider/Omron

|

|

||

|

Displacement pickup

|

Jefran

|

Italy

|

||

|

Hydraulic oil seal

|

DZ

|

Taiwan,China

|

||

|

Intermediate relay/Thermal relay/Contactor/Air switch/Circuit breaker

|

Schneider

|

France

|

||

|

Servo System

|

Delta/Inovance

|

Taiwan,China

|

||

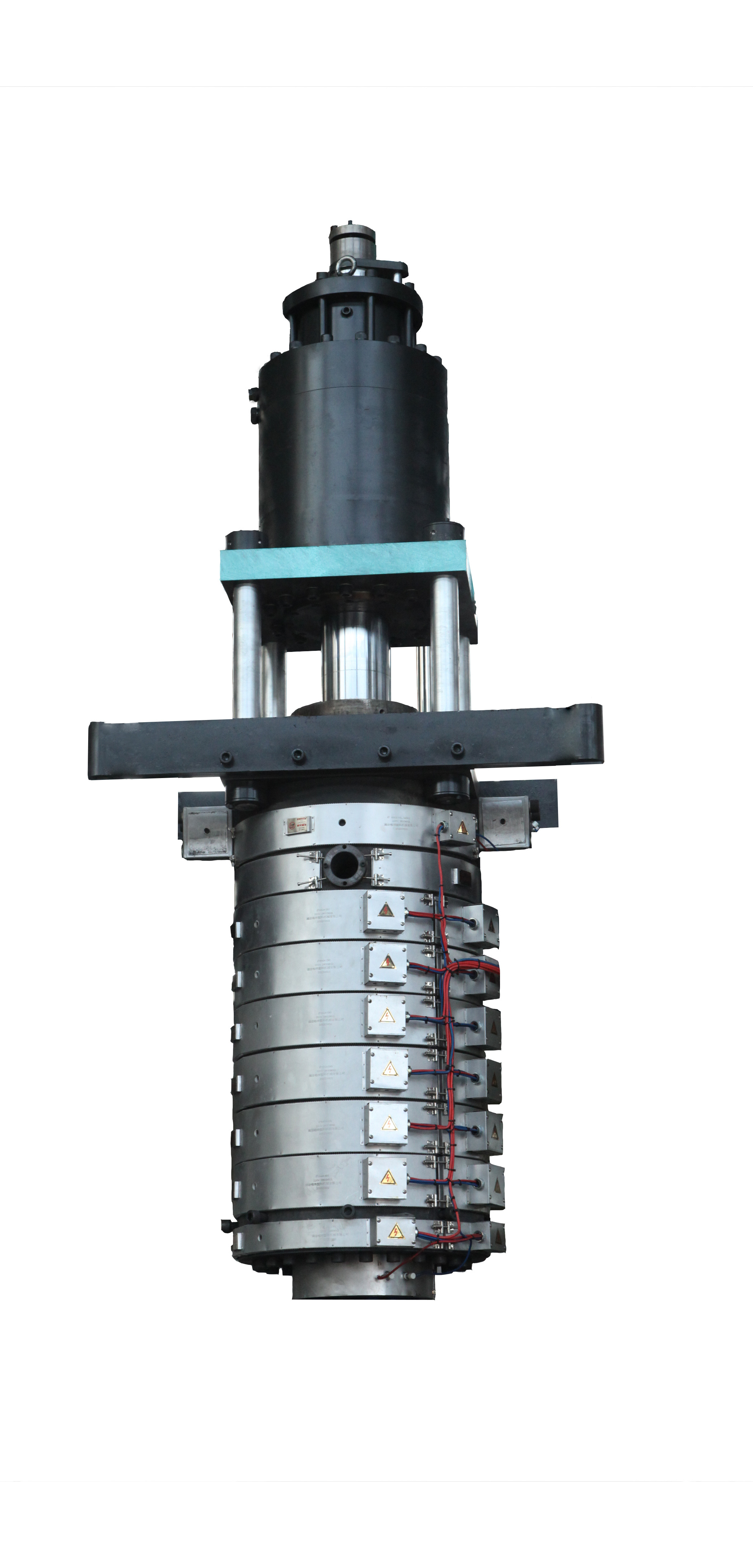

Details Images

Die Head

Advantage:

Our Company Patent Technology

It can be designed from single to 8 layers

Material:

Nitrided 38CrMoAIA Material.

High precision core pin processing technology

Heating way:

Mica,Electromagnetic or far-infrared heating Choices

Control:

100 point wall thickness control system, Moog valve and electronic ruler, high precision co

operatio.

Clamping Unit

Three cylinders with three platen construction advantages:

Reduce recycled time.Enlarged locking force for better products.

Longer using life:

R

uning on guide rails and all platens on sliders,run smoothly.

The clamping force is evenly distributed on the platen,which is not easy to deform

.

No noise:

Servo system makes pump and motor runing only when it needs.

Energy-efficient:

Prefill oil tank makes operation

efficiency and energy saving.

Serovo motor saves more energy.

The advantages of Siemens Motors

1. Solid parts connection:

Implement Siemens motor assembly standard, modular design, modular installation, improve the

reliability of parts connection;

reliability of parts connection;

2. High performance protection level:

All motors are designed with IP55 protection level, they can be used in outdoor or dusty and humid environment;

3. Improve the insulation performance and increase the service life of the motor:

all standard motors adopt the F-class insulation system and are assessed according to the B-class insulation to increase the reliability of the motor operation and improve the service life of the motor;

4.

There are after-sales service points in countries all over the world

Main control unit

12''

Siemens

Touch Screen

100 points MOOG thickness controller DigiPack III [Touch screen type]

Equipped with emergency quick switch

Temperature Controller

Real time monitoring

Easy to identify,convenient to operate

Extruders

Motor connects with gear box directly

Reduce energy loss,easy maintaining

Guide rails and sliders

HIWIN brand.High operation accuracy.

Longer using and service life

Hydraulic valve

Equipped famous brand,more stable and reliable,longer using life.

Oil pump

SUMITOMO servo gear pump

Significant energy saving effect.

Servo system

Save electricity and more quiet, precise, durable and efficient.

Products Layer Analysis

We can manufacture one - to - ten - layers production Blow Molding Machines

OUTER LAYER

:HDPE material with UV protection, natural or pigmented.

MIDDLE LAYERS

: Use regrind material to reduce product cost,It can also serve as adhesive layer, EVOH layer according to product application.

INNER LAYER

: 100% Virgin material Food Grade.

Such as

:Outer layer-15% MIDDLE LAYERS-70% INNER LAYER-15%

Hot Searches