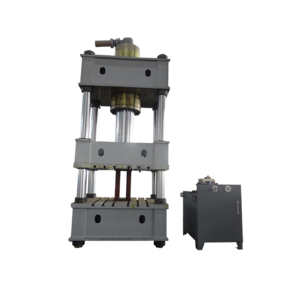

SMC resin heat pressing hydraulic manhole cover press machine, Hydraulic control adopts to insert set valve integrated system, decrease let out Point.Movement reliability, durable and long life span, It is constant pressure to realize with calm in the first place and calm procedure two develop technology, have to insure press the function of delay time, The route of working pressure may be regulated in assigned scope, adopt buttons for centralized control, Can realization manual, Semi-automatic, automatic 3 operate form.

Application field:

This series of hydraulic presses is suitable for the pressing process of plastic materials, such as stamping, bending, flanging and thin stretching, etc. It can also be used for the correction, press-fit, plastic products and powder products.