- Product Details

- {{item.text}}

Quick Details

-

Production Capacity (kg/h):

-

150 - 200 kg/h

-

Brand Name:

-

JINGXIN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1.4*0.9*1.5m

-

Power (kW):

-

24

-

Weight (T):

-

0.4

-

Type:

-

Recycling machine

-

Name:

-

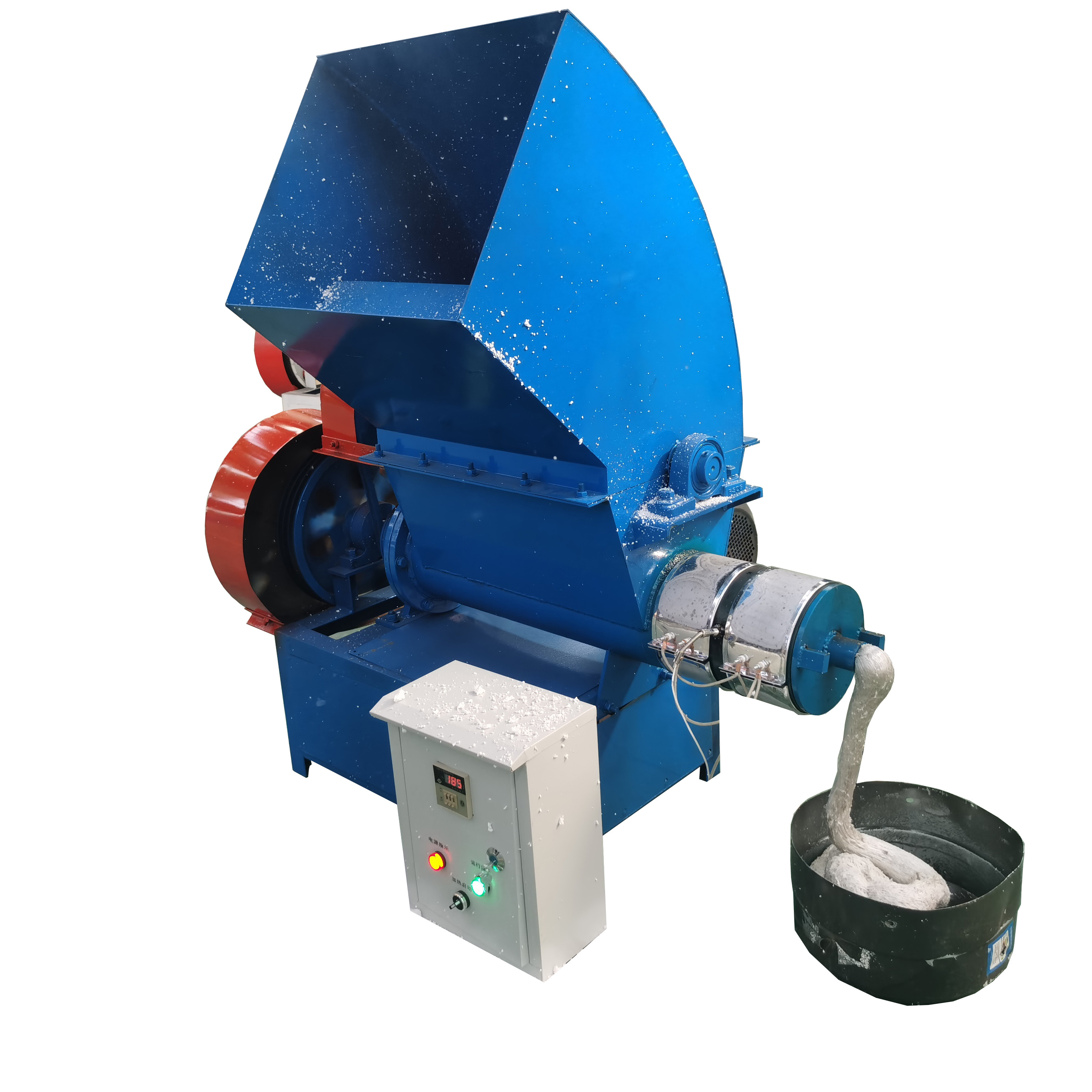

Foam plastic melting machine

-

Application:

-

Eps Recycle

-

Material:

-

Steel Structure

-

Power of motor:

-

18.5 kw

-

Power of heater:

-

2.0 kw

-

Cutting Speed:

-

1440 RPM

-

Feeding inlet size:

-

600*400 mm

-

screw length:

-

800 mm

-

Weight:

-

600 kg

Quick Details

-

Max.Production Capacity (kg/h):

-

200

-

Place of Origin:

-

Henan, China

-

Machine Type:

-

Plastic melting machine

-

Production Capacity (kg/h):

-

150 - 200 kg/h

-

Brand Name:

-

JINGXIN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1.4*0.9*1.5m

-

Power (kW):

-

24

-

Weight (T):

-

0.4

-

Type:

-

Recycling machine

-

Name:

-

Foam plastic melting machine

-

Application:

-

Eps Recycle

-

Material:

-

Steel Structure

-

Power of motor:

-

18.5 kw

-

Power of heater:

-

2.0 kw

-

Cutting Speed:

-

1440 RPM

-

Feeding inlet size:

-

600*400 mm

-

screw length:

-

800 mm

-

Weight:

-

600 kg

Features

This waste foam plastic hot melting machine was specifically designed to melt and extrude beads of expanded polystyrene (EPS) for waste removal purposes.

There is a hopper made of stainless steel on top of this foam plastic melting machine ,feeds the beads from a collection bag into a set of horizontally mounted heated rolls, which are used to melt the beads. By incorporating a vacuum system, the beads may be deposited directly into this foam melt machine from a foam trim, route or groove operation.

As the heated rolls revolve, the beads melt and then are scraped from each roll while in the liquid state. As this liquid foam falls into a container located under the rolls, it cools and solidifies. The transformation of EPS waste from beads to extruded sheets saves tremendous plant space and disposal costs.

There is a hopper made of stainless steel on top of this foam plastic melting machine ,feeds the beads from a collection bag into a set of horizontally mounted heated rolls, which are used to melt the beads. By incorporating a vacuum system, the beads may be deposited directly into this foam melt machine from a foam trim, route or groove operation.

As the heated rolls revolve, the beads melt and then are scraped from each roll while in the liquid state. As this liquid foam falls into a container located under the rolls, it cools and solidifies. The transformation of EPS waste from beads to extruded sheets saves tremendous plant space and disposal costs.

Recommend Products

Packing & Delivery

⭐ For small-sized goods shipped by express, usually the packaging method is carton/wooden box;For large-sized goods shipped by land/sea/air, we will pack the goods with standard export wooden boxes.

⭐ If the goods you ordered we have in stock, we usually deliver out within 7-10 working days.If the goods need to be pre-ordered,you can contact us to determine the exact delivery time.

⭐ If the goods you ordered we have in stock, we usually deliver out within 7-10 working days.If the goods need to be pre-ordered,you can contact us to determine the exact delivery time.

Hot Searches