- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

5170*5200*2300mm

-

Motor Power (kW):

-

27kw

-

Model Number:

-

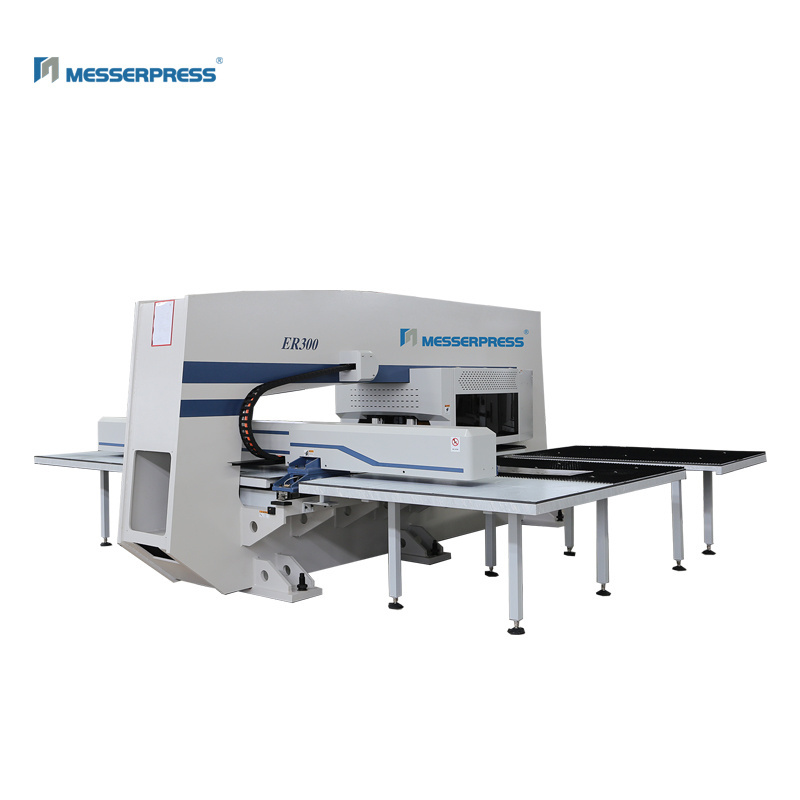

ER300

-

Weight (T):

-

15

-

Marketing Type:

-

New Product 2023

-

Max. Sheet Thickness:

-

≤6.35

-

Accuracy:

-

±0.1

Quick Details

-

Slide Stroke (mm):

-

32

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Messerpress

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

5170*5200*2300mm

-

Motor Power (kW):

-

27kw

-

Model Number:

-

ER300

-

Weight (T):

-

15

-

Marketing Type:

-

New Product 2023

-

Max. Sheet Thickness:

-

≤6.35

-

Accuracy:

-

±0.1

Overview

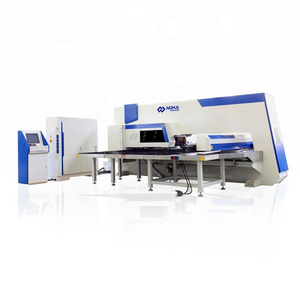

Servo Cnc Turret Punch Press And Features

The new generation of Messerpress turret punch is a low energy, high efficiency turret punch with low environmental and maintenance cost,The Messerpress can be configured in 30 ton.

The punching force is coming from the main servo motor,which transmit the force by a directly drived connecting rod,this transmitting structure retains the advantage of mechical transmitting method, it is mature and reliable.The eliminated mechanical gap enables a high driving precision,low noise and long service life features.

Turret can realize punch cutting, forming,rolling,letting and so on. It is intelligent servo ram and has Rexroth Components which made in Germany. This has 32 stations mosaic turret, prevent wear and has Rexroth indrawork Mix CNC Controlling System.

Products Description

Frame

O-type closed integral welding press frame special for servo punch press.Holistic welding structure, stress relief from tempering treatment.The strong rigidity and high tonnage ensure the stable accuracy for long time, extend the service life of the machine and tools, and improve the positioning precision, reliability and durability.

Full Auto Indexed Station

Unique worm gear structure to ensure the accuracy of positive and negative bidirectional transmission.

Single import synchronous belt drive to ensure synchronization between up and down.

Worktable

The worktable surface with hard brush and steel ball, to lower down the noise while working and protect the surface of the sheet.

Seamless worktable design to avoid collision during sheet metal movement.

Folding table design, side auxiliary platform automatic folding control, easy to change tooling.

Aluminum edging design, side aluminum edging,

protect the worktable surface from wear.

Side loading auxiliary roller, easy to loading the plate.

Floatable Pneumatic Clamps

The pneumatic floatable clamps reduce the deformation of the plate.

The self-protection function makes no dead area for punching on sheet.

The clamp automatically floats when clamping the plate, convenient for the plate clamp.

Automatic unloading when the clamp returns

Control System BEST FOR OPERATOR

Network communication, software can infinitely speed variation. Real-time display of machining graphics, intuitive and humanized interface. With one key to return to the reference point function, can set a key loading positions.

According to the plate thickness automatic adjust the punch preloading height. Can set high precision, extreme speed, normal and so on many kinds of processing mode.

Automatic detection of clamp position.Break point processing function, analog processing function.

One key operation, cycle start function.

All stations have their own independent protection area, and own independent processing parameters. Field programming, background programming

Turret and Tooling

Precision wear-resistant guide holder inlaid on turret,

large machining center in pairs processed

International standard Japan AMADA long guide tool,

Reasonable stations distribution, tooling in common use.

Specification

|

NO.

|

Name

|

|

Specification

|

Unit

|

||

|

1

|

Press Capacity

|

|

300

|

kn

|

||

|

2

|

Transmission Type

|

|

Servo

|

|

||

|

3

|

Frame Construction

|

|

O-frame

|

|

||

|

4

|

Max.Sheet Size

|

X axis

|

5000(With one re-positioning)

|

mm

|

||

|

|

|

Y axis

|

1250/1500/2000

|

mm

|

||

|

5

|

Max sheet thinckness

|

|

≤6.35

|

mm

|

||

|

6

|

Max Diameter

|

|

φ88.9

|

mm

|

||

|

7

|

Max Punching Stroke

|

|

32

|

mm

|

||

|

8

|

Max Nibbling Speed

|

|

1800

|

hpm

|

||

|

9

|

1mm pitch,6mm punch stroke

|

|

750

|

hpm

|

||

|

10

|

25.4mm pitch,4mm punch stroke

|

|

400

|

hpm

|

||

|

11

|

No. of Clamps

|

|

3

|

pcs

|

||

|

12

|

No.of Re-positioning Cylinder

|

|

2

|

set

|

||

|

13

|

Turret Stations

|

|

32

|

pcs

|

||

|

14

|

No.of Controlling Axis

|

|

5(X,Y,T,C,A)

|

pcs

|

||

|

15

|

Tool Distribution

|

|

16A/12B/2BZ/2C/2D

|

|

||

|

16

|

Worktable Structure

|

|

Brush and ball mixed

|

|

||

|

17

|

Max.Feeding Speed

|

X axis

|

90

|

m/min

|

||

|

|

|

Y axis

|

80

|

m/min

|

||

|

|

|

X,Y combined

|

110

|

m/min

|

||

|

18

|

Turret Speed

|

|

30

|

rmp

|

||

|

19

|

Rotational Tool Speed

|

|

40

|

rmp

|

||

|

20

|

Punching Accuracy

|

|

±0.10

|

mm

|

||

|

21

|

Max . Sheet Weight

|

|

150

|

kg

|

||

|

22

|

Air pressure

|

|

0.6

|

mpa

|

||

|

23

|

Power

|

|

63

|

kw

|

||

|

24

|

Clamp Dead Area Detection

|

|

Yes

|

|

||

|

26

|

Clamp Splint Loose Alarm Device

|

|

option

|

|

||

|

27

|

Plate Warping Alarm

|

|

Yes

|

|

||

|

28

|

Clamp Automatically Float Down

|

|

Yes

|

|

||

|

29

|

Roller Auxiliary Feeding

|

|

Yes

|

|

||

|

30

|

Over size

|

Length

|

5170/5670/6670

|

mm

|

||

|

|

|

Width

|

5200/5200/5200

|

mm

|

||

|

|

|

Height

|

2300/2300/2300

|

mm

|

||

Turret Tooling

Thin Turret CNC Tooling

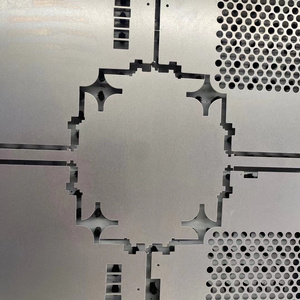

1.All edges of the punch pins are made of special steel mold and are processed by vacuum heat treatment. The edge of the punch pin hardness is HRC60C-63C.

2.The dies are made of high-quality steel mold and are processed under vacuum heat treatment. All edges of the die are designed to prevent scrap or waste material from rebounding, jumping, and floating upwards.

3.The surface of the guide is processed with special technology to enhance wear resistance. The inner diameter of the guide sleeve has a well-lubricated groove design, which makes it difficult to go through wear and tear over time. Simultaneously, there is less abrasion for the CNC turret punch press of fixed sleeve.

4.The stripper plate is locked with a spring that is made of a high grade spring steel which is not easy to break. The stripper plate locking screw is a custom-made steel which can be directly dismantled and reassembled with a cross screwdriver, not slipping easily.

5.The molds of Thin turret CNC punch has B. C, D three stations and are suitable for Amada, Jinfangyuan d other domestic international.

Related Products

Packing & Delivery

The packaging options available include plastic, wooden, or any other type as per the customers' preference.

Hot Searches