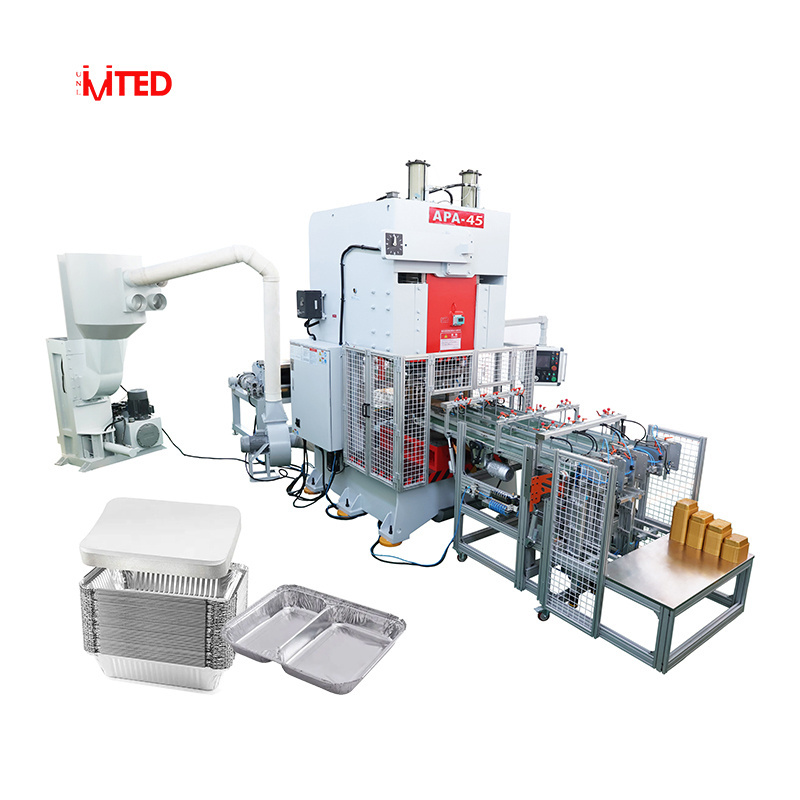

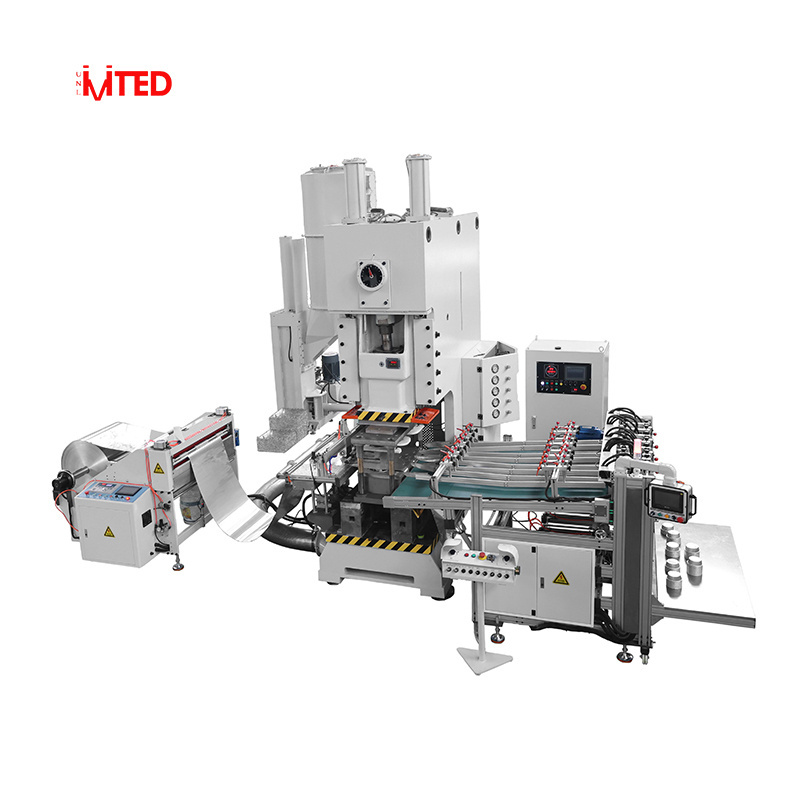

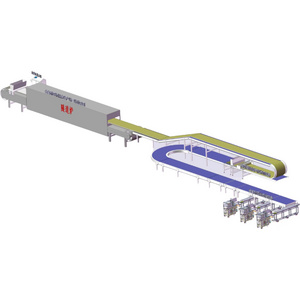

Components of this production line:

1. Auto-feeder with lubrication system

2. Punching machine

3. Auto-stacker

4. Auto-scrap collector

5. Electrical control system

6. Stamping mold

Production Steps:

Lubricating material------Feeding material------Punching by the press------Collecting product by the stacker------Collecting scrap by the scrap collector

Our Advantage:

1. Our guarantee time is one year, if any component is damaged during guarantee time, we can send the component to the customer by DHL, TNT freely.

2. Our factory can send our engineer to the customer’s factory install, commission and training freely. The customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to our factory to learn the operation and maintains freely.

3. Our factory provide the service for the customer forever, if the customer need operation help, can contact us by MSN, Skype, Email and Telephone at any time, we provide 24 hours on-line service. Our factory also will make DVD to show the operation steps for the customer.

Main features:

1、The production line can be configured with single-cavity and multi-cavity molds, which can increase the productivity exponentially.

2、Adopt high quality control system and electrical device to make the production more accurate, stable and safe.

3、We can design and customize the production line with different configurations and electrical devices according to customers' needs to meet different customers' demands.