Special developed for the jam, air blowing from both front and side way ensure the sheet feeding one by one without double Ton and

easy operation.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ROYAL PACKING

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

6.2x6.3x1.85

-

Weight:

-

10000 kg

-

Max. sheet size:

-

1020x850mm

-

Thickness of cutting paper:

-

180~500 gsm

-

Min. sheet size:

-

470x360mm

-

Max. speed:

-

3600sheets/hour

-

Total power:

-

13KW

-

Power Supply:

-

3P 380V AC 50Hz

-

Max.card size:

-

120*150mm

-

Min.card size:

-

50*70mm

-

Keyword:

-

Slitting Cutting Machine

Quick Details

-

Type:

-

Paper Cutting Machine

-

Production Capacity:

-

3600sheets/hour

-

Max. workable width:

-

1020

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ROYAL PACKING

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

6.2x6.3x1.85

-

Weight:

-

10000 kg

-

Max. sheet size:

-

1020x850mm

-

Thickness of cutting paper:

-

180~500 gsm

-

Min. sheet size:

-

470x360mm

-

Max. speed:

-

3600sheets/hour

-

Total power:

-

13KW

-

Power Supply:

-

3P 380V AC 50Hz

-

Max.card size:

-

120*150mm

-

Min.card size:

-

50*70mm

-

Keyword:

-

Slitting Cutting Machine

We are the biggest manufacturer for packaging machinery in North of China.

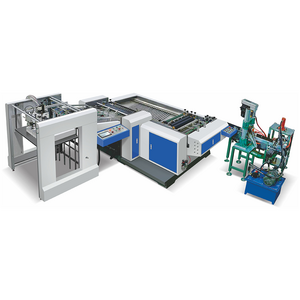

This machine is mainly used for the automatic production line of playing and cartoon cards. It can slit sheets into various sizes of cards with on-line card collation and corner cut. The main feature of this machine is that there will be no disorder of the cards after slitting and collation. It is an ideal machine for playing card and cartoon cards industry which can increase the working efficiency and save labor—totally replace manual cards collation.

1. It is the first product in China that provides specialized equipment for process printed playing card or other card, speed is 1600 sheets/hour.

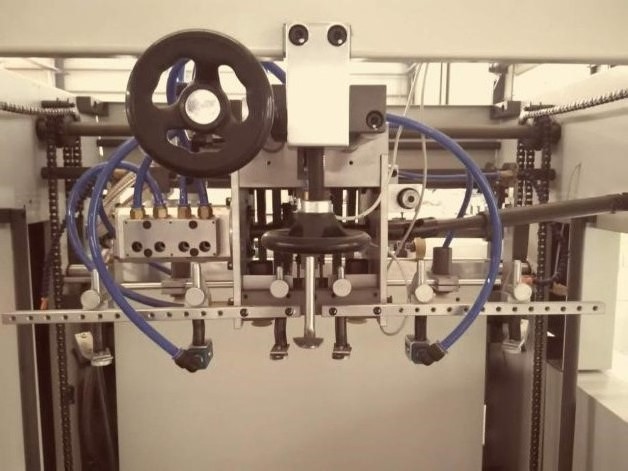

2. The special pressure spokes cutting system ensure the high precision (±0.15mm)

3. Collecting by New structure , scaly transport ,servo system control collating to ensure the cards is not disordered between every deck and every cards

4. Corner punching at the same time , the waste edge only within 0.75mm

2. The special pressure spokes cutting system ensure the high precision (±0.15mm)

3. Collecting by New structure , scaly transport ,servo system control collating to ensure the cards is not disordered between every deck and every cards

4. Corner punching at the same time , the waste edge only within 0.75mm

Feeder:

Side pull:

Difference from others, sheets go right to the side lay when feeding and complete web-guid automatically,ensure the precision in

next cutting part.

next cutting part.

PLC control system:

Controlled by PLC system, which ensures auto die-cutting of single or double cards

Double-sides jogger ensures the high precision which makes the waste edge is cut only within 0.75mm

Double-sides jogger ensures the high precision which makes the waste edge is cut only within 0.75mm

|

Max. sheet size

|

1020×840mm

|

Max. speed

|

1600sheets/hour

|

|

|

Min. sheet size

|

550×400mm

|

Total power

|

9KW

|

|

|

Net weight

|

7.8T

|

Sheet thickness

|

180~500 gsm

|

|

|

Max.card size

After slitting |

150*120mm

|

Min.card size

After slitting |

80*50mm

|

|

|

Max.card size

|

148*118mm

|

Min.card size

|

78*48mm

|

|

|

Power Supply

|

3P 380V AC 50Hz

|

Dimension

|

4400×4380×1850mm

|

|

Hot Searches