- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1000 KG

-

Product Name:

-

CH4 Methane Purification Plant

-

Plant size:

-

100~100000Nm3/h

-

Methane purity:

-

95%-98%

-

Methane recovery:

-

95%-99%

-

Carbon dioxide removal rate:

-

99%

Quick Details

-

Place of Origin:

-

China

-

Production Rate:

-

100kt/a

-

Voltage:

-

380V/200V 50HZ

-

Weight:

-

1000 KG

-

Product Name:

-

CH4 Methane Purification Plant

-

Plant size:

-

100~100000Nm3/h

-

Methane purity:

-

95%-98%

-

Methane recovery:

-

95%-99%

-

Carbon dioxide removal rate:

-

99%

PSA Pressure Swing Absorption M

ethane

CH4 Gas Generator Equipment

Cost-Effective Landfill Gas Extraction Units 97%Purity Oil And Gas Methane Gas Production Plant For Wetlands

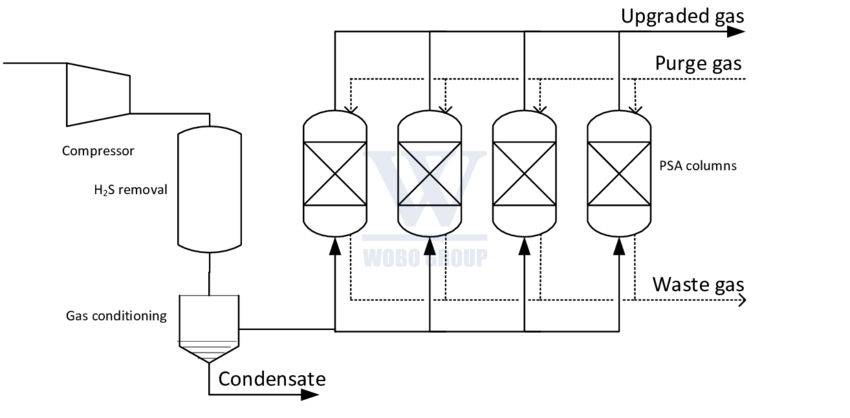

Pressure Swing Adsorption (PSA) technology is based on the physical adsorption of gas molecules on the internal surface of a specific adsorbent (a porous solid substance). It exploits the characteristics of the adsorbent, which prefers to adsorb high-boiling components at the same pressure, resists adsorbing low-boiling components, and exhibits increased adsorption capacity at high pressure and decreased adsorption capacity at low pressure. When the feed gas passes through the adsorption bed at a certain pressure, the high-boiling impurities relative to methane are selectively adsorbed, while the low-boiling methane passes through the adsorption bed. This achieves the separation of methane from impurities.

Product Parameters

|

Device Name

|

PSA Methane Purification Unit

|

|

Device Performance

|

100~30000Nm3/h

|

|

Methane Purity

|

60~98%

|

|

Methane Recovery Rate

|

75~99%

|

|

Application Areas

|

Concentration of methane from coal mine gas; purification of methane from biogas; removal of impurities above C2 from natural gas;

purification of landfill gas; coal-to-gas conversion; methane enrichment in shale gas. |

The feed gas enters the PSA system at a certain pressure and temperature. In the PSA-CH4 system, each adsorber undergoes a sequence of steps at different times, including adsorption, first-stage pressure equalization reduction, second-stage pressure equalization reduction, purging, second-stage pressure equalization increase, first-stage pressure equalization increase, and finally pressurization. During the purging step, the adsorbed impurities are discharged from the adsorber, and most of the remaining impurities are further desorbed during the evacuation step. The product gas CH4 is then supplied to users, while the desorbed gas is directed away from the fuel system.

Project Case

Product Application

1. Concentration of methane from coal mine gas.

2. Purification of methane from biogas.

3. Removal of impurities above C2 from natural gas.

4. Purification of landfill gas.

5. Coal-to-natural gas conversion.

6. Concentration of methane from shale gas.

Related Products

Hot Searches