- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

history:

-

more than 30 years with professional technology

-

Advantage1:

-

without oil spiliing or off pressure

-

Advantage2:

-

low noise and high safety

-

Advantage3:

-

Four-colum and angle design structure ensure machine in duiablity

-

Power(W):

-

33kw-110kw

-

Control System:

-

Automatic Control

-

Usage:

-

Produce Rubber Moulded Products

-

Heating mode:

-

Electricity

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GY

-

Weight:

-

8000, 7t-52t

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

history:

-

more than 30 years with professional technology

-

Advantage1:

-

without oil spiliing or off pressure

-

Advantage2:

-

low noise and high safety

-

Advantage3:

-

Four-colum and angle design structure ensure machine in duiablity

-

Power(W):

-

33kw-110kw

-

Control System:

-

Automatic Control

-

Usage:

-

Produce Rubber Moulded Products

-

Heating mode:

-

Electricity

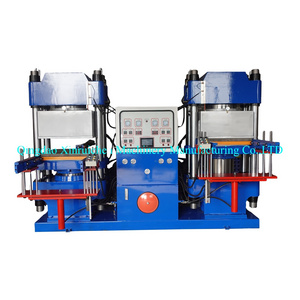

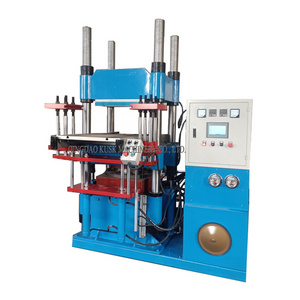

Rubber O-ring Making Machine / o Ring Vulcanized Machine/ vacuum Vulcanizing Press

about us:

We , Qingdao Guangyue Rubber Machinery Mnanufacturing Co.,Ltd make high quality rubber machine, from materials to producing, we use the good quality material , complete management system , also excellent aftersale service , we hope to be one reliable factory for you!

. special manufacturer that has professional producing team and technical support

- Exclusive and unique solution can be provided to our customer by our well-trained and prof essional engineers and staff.

- best after sale---follow the whole producing situation,provide photos of machines loaded into containers, track the operating and using situation of client in case of any problems occur.

- reasonable price and flexible delievery time

- more than 30 years of experience of exporting ability

Parameters of tube curing press machine

Technical parameters:

| Type | 100T | 150T | 200T | 250T | 300T | 300T XL | 400T | 500T |

| Clamping force(Ton) | 100 | 150 | 200 | 250 | 300 | 300 | 400 | 500 |

| Stroke(mm) | 250 | 250 | 280 | 300 | 300 | 300 | 300 | 300 |

| Heating plate size(mm) |

400*400

448*460 |

420*420

460*460 |

503*508

545*560 |

600*600

600*650 |

600*600

650*650 |

700*700

700*700 |

700*700

800*800 |

800*800

850*850 |

| Diameter of cylinder(mm) | ∅250 | ∅310 | ∅355 | ∅400 | ∅450 | ∅450 | ∅500 | ∅560 |

| Horsepower(HP) | 7.5*2 | 7.5*2 | 10*2 | 10*2 | 10*2 | 10*2 | 15*2 | 15*2 |

| Type of mold opening | 2RT/3RT/4RT UP-DOWN IN-OUT 2RT/3RT/4RT | |||||||

| Double shaft thermal electricity(kw) | 14 | 22.5 | 27 | 34.5 | 36 | 45.5 | 46.5 | 48 |

| Total power(kw) | 19.5 | 33.5 | 42 | 49.5 | 51 | 60.5 | 68.5 | 70 |

| Gross weight(kg) | 6000 | 7500 | 8500 | 11000 | 13000 | 15000 | 19500 | 24000 |

| Machine size(cm) | 270*230*227 | 300*230*235 | 320*260*250 | 360*295*265 | 365*295*270 | 380*300*290 | 385*315*300 | 410*320*310 |

4 Detailed pictures

5 standard wood package .

6 Our production workshop

7 Clients visit our factory

8 Certificates

9 Welcome to visit OUR FACTORY ,we can show you the workshop and machine in our client factory