- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V~3N/50Hz/60Hz

-

Power:

-

17kw

-

Dimension(L*W*H):

-

1000*600*3350mm

-

Weight (KG):

-

1000

-

After-sales Service Provided:

-

Online Service

-

Keywords:

-

Full-Automatic

-

Function:

-

High Efficiency Drying

-

Feature:

-

High Efficiency Low Cost

-

Heating source:

-

Steam

-

Advantage:

-

Low Consumption High Efficiency

-

Raw material:

-

304 Sainless Steel

-

Usage:

-

Food Used

Quick Details

-

Type:

-

Fluid Bed Drying Equipment

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HaoMai

-

Voltage:

-

380V~3N/50Hz/60Hz

-

Power:

-

17kw

-

Dimension(L*W*H):

-

1000*600*3350mm

-

Weight (KG):

-

1000

-

After-sales Service Provided:

-

Online Service

-

Keywords:

-

Full-Automatic

-

Function:

-

High Efficiency Drying

-

Feature:

-

High Efficiency Low Cost

-

Heating source:

-

Steam

-

Advantage:

-

Low Consumption High Efficiency

-

Raw material:

-

304 Sainless Steel

-

Usage:

-

Food Used

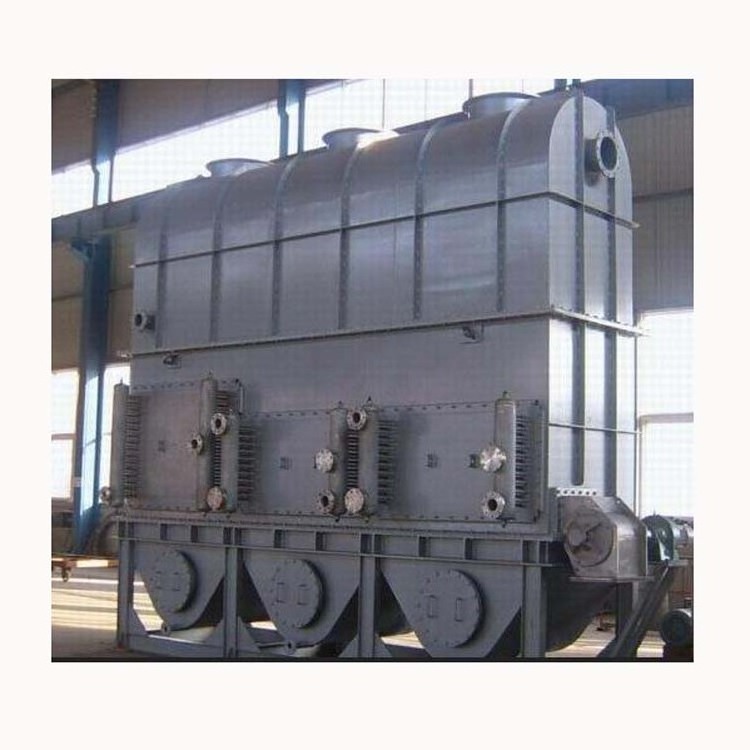

Products Description

WORKING PRINCIPLE

The solid material is fed to fluidized bed dryer by the feeder. The blower will blows the filtered clean hot air heated into the fluidized bed at the bottom of the distribution plate and fluidization to gas-solid heat and mass exchange to heat the solid material. The dried material is discharged from the discharge outlet. The exhaust gas is discharged from the top of the fluidized bed and the solid power will be collected by the cyclone separator or cloth bag duster.

DESCRIPTION

The Boiling dryer is also call as fluidize-bed. It consists of air filter, heater, fluidized-bed main machine, feeder, cyclone

separator, cloth bag duster, high-pressure centrifuge fan, and operation table. The dust collector shall be equipped according to the properties of raw materials. You can use cyclone separator or cloth bag duster according to the materials characteristics, the cyclone separator is mainly used for high specific gravity materials and the cloth bag duster is mainly used for powder and small granule materials. The air feeding device and belt conveyor is optional. The heat source can use steam, electricity, hot air furnace as per customer requirements.

Feeding Mode:

1)Star feeding;

2) Star feeding with pneumatic conveying;

3) Belt conveyor;

4) Customized

II. Automated production can be realized.

III. Customized design as per user requirements.

IV. The fan power is depends on the material types.

Installation Instructions

1. All equipment should be placed flat, fixed with foot screws, the components of a good seal.

2. Fan can be placed in the outdoor or indoor self-silencer. Layout can be adjusted as appropriate depending on the

circumstances.

Scope of application

This dryer is widely used for raw materials, foodstuff, grain processing, feed, and etc.

Example applicable materials such as drinks, feed, resin, citric acid and other powders. The suitable drying diameter of raw material is 0.1~6mm. The best drying diameter of raw material will be 0.5~3mm.

Specification

|

Model

Specification |

XF0.25-1

(XF10) |

XF0.25-2

(XF20) |

XF0.25-3

(XF30) |

XF0.25-6

|

XF0.3-2

|

XF0.3-4

|

XF0.3-6

|

XF0.3-8

|

XF0.3-10

|

|||||||||

|

Area of Bed Layer

(m2) |

0.25

|

0.5

|

1.0

|

1.5

|

0.6

|

1.2

|

1.8

|

2.4

|

3.0

|

|||||||||

|

Drying Capacity

(kg h2O/h) |

10-15

|

20-25

|

30-45

|

52-75

|

-30

|

42-60

|

63-90

|

84-120

|

105-150

|

|||||||||

|

Fan Power(kw)

|

5.5

|

7.5

|

15

|

22

|

7.5

|

18.5

|

30

|

37

|

48

|

|||||||||

|

Inlet Air Temperature

(oC) |

120-140

|

120-140

|

120-140

|

120-140

|

120-140

|

120-140

|

120-140

|

120-140

|

120-140

|

|||||||||

|

Material Temperature

(oC) |

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

|||||||||

|

Overall Dimension (Dryer Body)

L×W×H(m) |

1×0.6

×3.35 |

2×0.6

×3.35 |

4×0.6

×3.35 |

6×0.6

×3.35 |

2×0.70

×3.4 |

4×0.7

×3.4 |

6×0.7

×3.4 |

8×0.7

×3.4 |

10×0.7

×3.4 |

|||||||||

|

Occupied Area (m2)

|

18

|

25

|

35

|

40

|

25

|

38

|

45

|

56

|

70

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Model

Item |

XF0.4-4

|

XF0.4-6

|

XF0.4-8

|

XF0.4-10

|

XF0.4-12

|

XF0.5-4

(XF50) |

XF0.5-6

|

XF0.5-8

|

XF0.5-10

|

|||||||||

|

Area of Bed Layer

(m2) |

1.6

|

2.4

|

3.2

|

4.0

|

4.8

|

2.0

|

3.0

|

4.0

|

5.0

|

|||||||||

|

Drying Capacity

(kg h2O/h) |

56-80

|

84

|

112-160

|

140-200

|

168-240

|

70-100

|

140-200

|

140-200

|

175-250

|

|||||||||

|

Fan Power(kw)

|

30

|

37

|

44

|

66

|

66

|

30

|

66

|

66

|

90

|

|||||||||

|

Inlet Air Temperature

(oC) |

120-140

|

120-140

|

120-140

|

120-140

|

120-140

|

120-140

|

120-140

|

120-140

|

120-140

|

|||||||||

|

Material Temperature

(oC) |

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

|||||||||

|

Overall Dimension (Dryer Body)

L×W×H(m) |

4×1

×3.58 |

6×1

×3.58 |

8×1

×3.58 |

10×1

×3.58 |

12×1

×4.1 |

4×1.2

×4.1 |

6×1.2

×4.1 |

8×1.2

×4.1 |

10×1.2

×4.1 |

|||||||||

|

Occupied Area (m2)

|

18

|

56

|

74

|

82

|

96

|

50

|

70

|

82

|

100

|

|||||||||

Detailed Images

Packing & Delivery

Hot Searches