- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

3000 kg

-

Production Capacity:

-

8-15m / mins

-

Power:

-

8kw, Hydraulic

-

Dimension(L*W*H):

-

6m * 1m * 0.8m

-

usage:

-

forming shutter door

-

door type:

-

roller shutter door

-

machine name:

-

metal shutter door roll forming machine

-

Automation:

-

Automatic

-

Raw material:

-

PPGI/Galvanized sheet

-

Raw material thickness:

-

0.5-1.5 mm

-

material of cutting blade:

-

Cr12

-

Control system:

-

Taiwan Delta

-

Color:

-

Client's Request

Quick Details

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

YUFA

-

Voltage:

-

8.5KW

-

Weight:

-

3000 kg

-

Production Capacity:

-

8-15m / mins

-

Power:

-

8kw, Hydraulic

-

Dimension(L*W*H):

-

6m * 1m * 0.8m

-

usage:

-

forming shutter door

-

door type:

-

roller shutter door

-

machine name:

-

metal shutter door roll forming machine

-

Automation:

-

Automatic

-

Raw material:

-

PPGI/Galvanized sheet

-

Raw material thickness:

-

0.5-1.5 mm

-

material of cutting blade:

-

Cr12

-

Control system:

-

Taiwan Delta

-

Color:

-

Client's Request

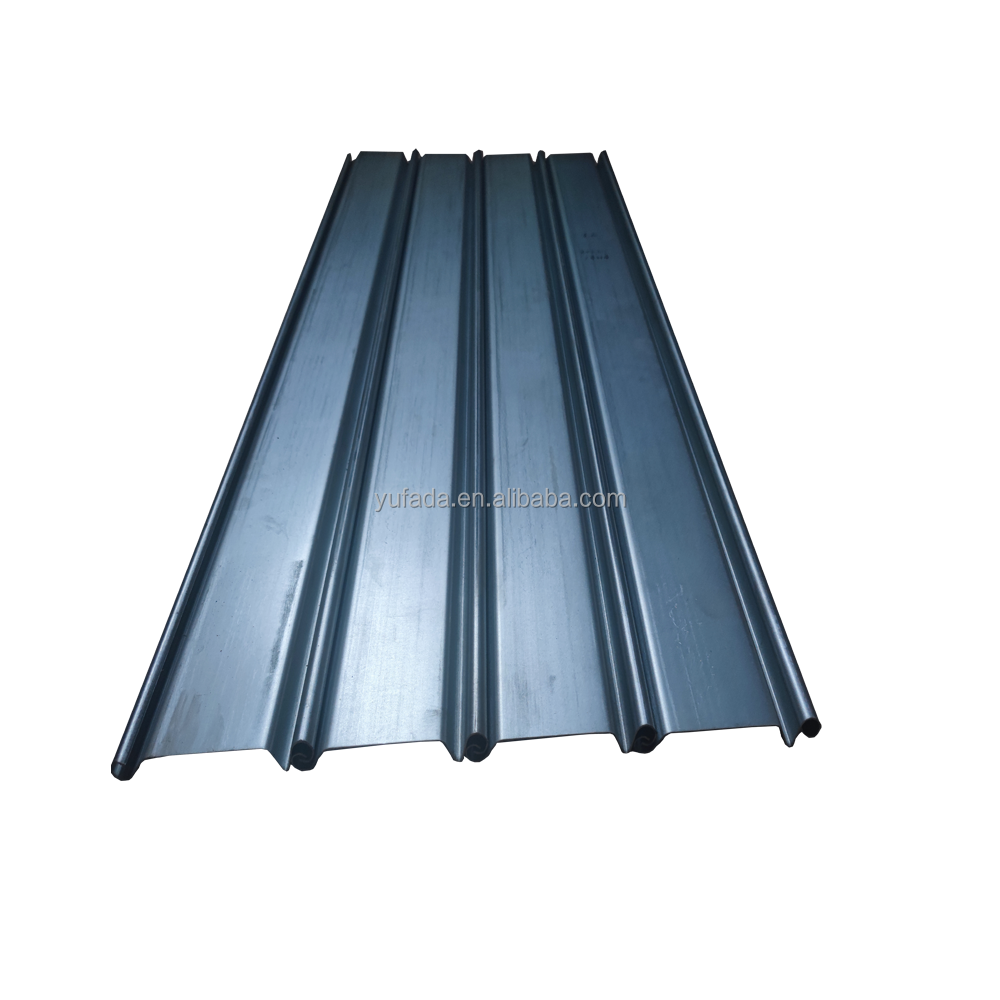

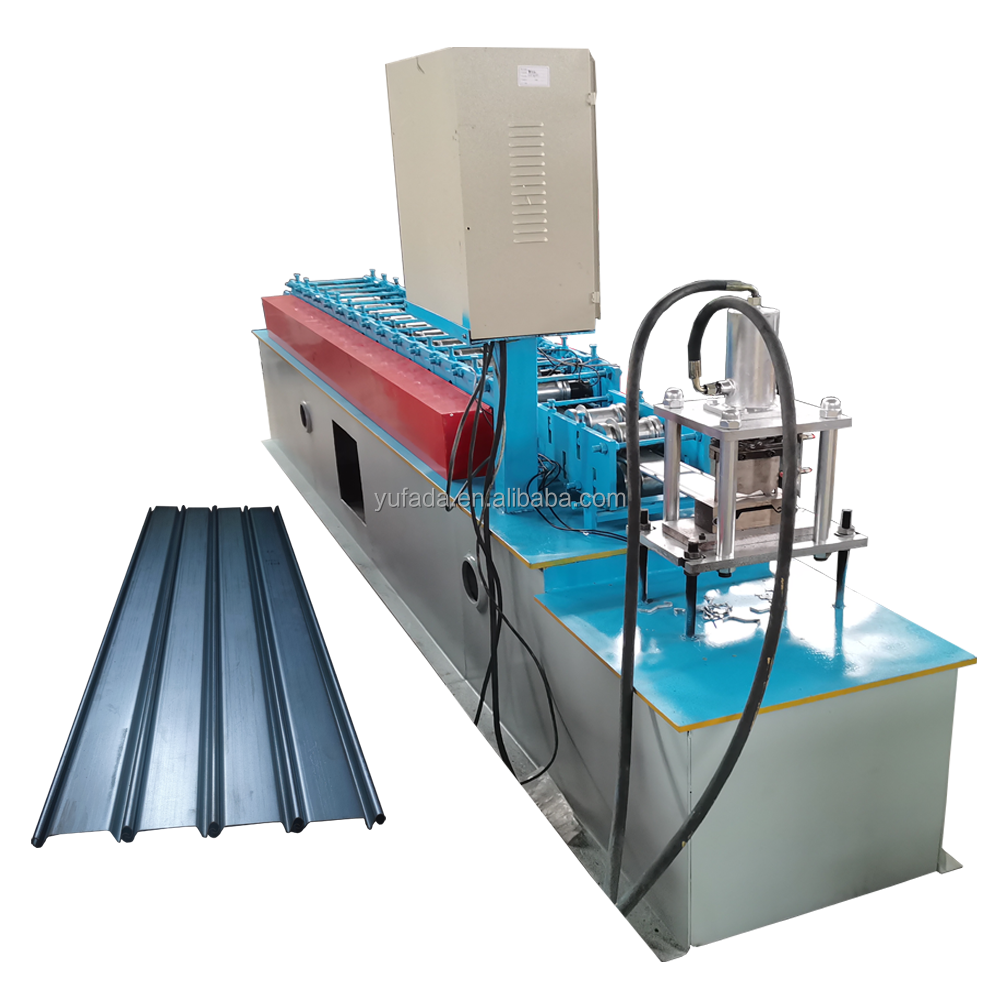

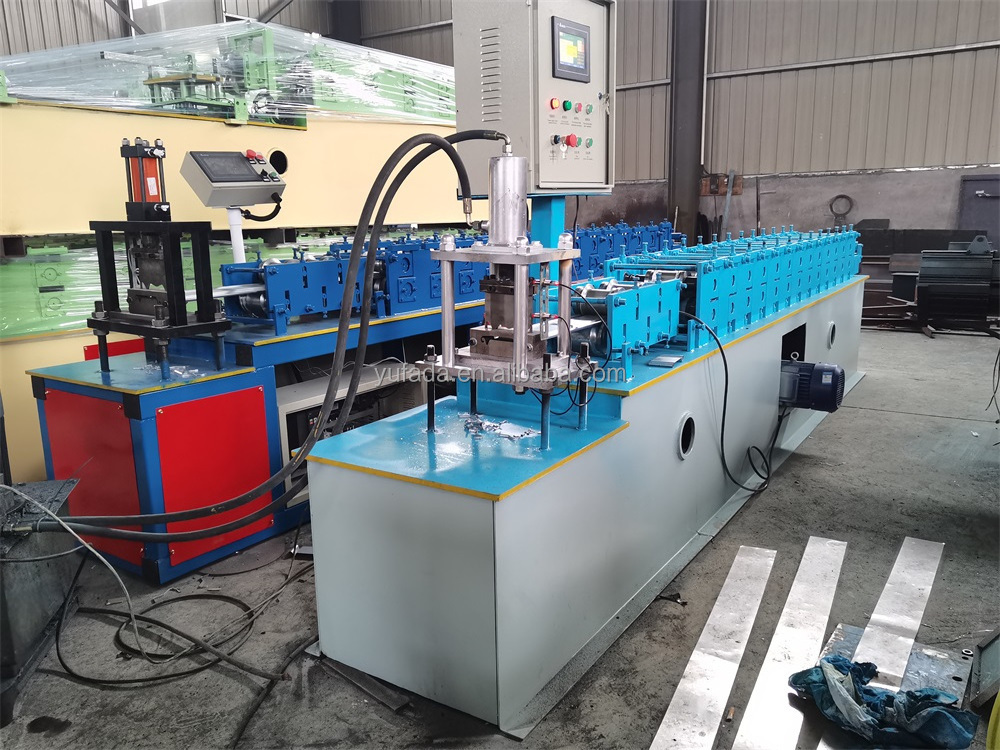

Automatically pressed galvanized metal plate roller shutter door frame pressed garage door panel cold bending equipment

Our company are professional product the shutter door roll forming machine manufacture , We manufacture and supply variants of shutter door roll forming machines in China, such as pu foam shutter door roll forming machine ,door frame roll forming machine , guide rail roll forming machine and so on , our machine export all over the world like india, south africa ,pakistan ,Brazil ,omen and so no , the shutter door roll forming machine raw material thickness 0.5mm-1.2mm, we also can make other shutter door roll forming machine as your requirement ,meet your need ,our company aim :reputation first, customer first

Work flow of Automatic rolling shutter motor roller making machine door roll forming:

Manual uncoiler-- roll forming machine-- PLC control box-- hydraulic cutter- output table

| 1 | Material of feeding material | PPGI GI |

| 2 | Thickness of feeding material | 0.5-1.2 mm coil sheet |

| 3 | Roller station | 13 stations |

| 4 | Shaft Diameter | 55 mm |

| 5 | Productivity | 10-20m/min |

| 6 | Rollers' material | 45# steel with 0.05 mm chrome |

| 7 | Shaft material | 45# steel with 0.05 mm chrome |

| 8 | Weight | 2.5 tons |

| 9 | length | 5.5 m |

| 10 | Voltage | 380V 50Hz 3phases |

| 11 | Control | PLC |

| 12 | Decoiler | 5 tons |

| 13 | Motor | 5.5 kw |

| 14 | Driving way | Chain transmission |

| 15 | Chain size | 1 inch |

| 16 | Cutting system | Hydraulic cutter |

SHUTTER DOOR ROLL FORMING MACHINE WITH EMBOSSING

Double running shutter door roll forming machine

Side rail roll forming machine

PU form panel roll forming machine

The components of the shutter door machine include: decoiler, roll forming machine body, hydraulic cutting, plc control system, main motor, pump station, receving table.

Equipment features: shutter door machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.