- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

A

-

Specification:

-

D50/75/110/160/200

-

Length:

-

50-200

-

Standard:

-

GB/T5836.1-2018

-

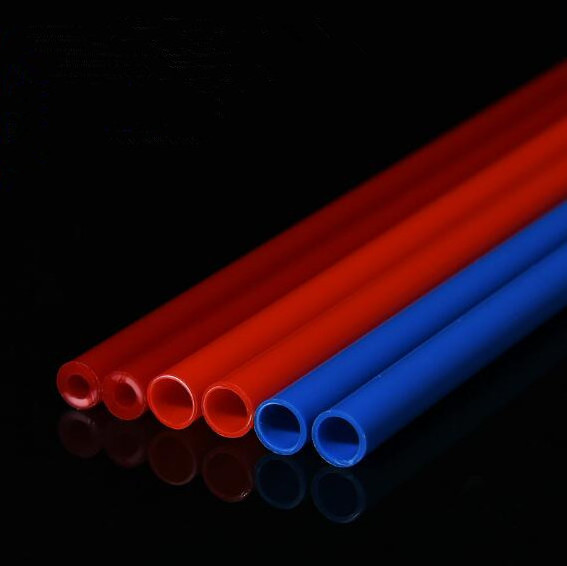

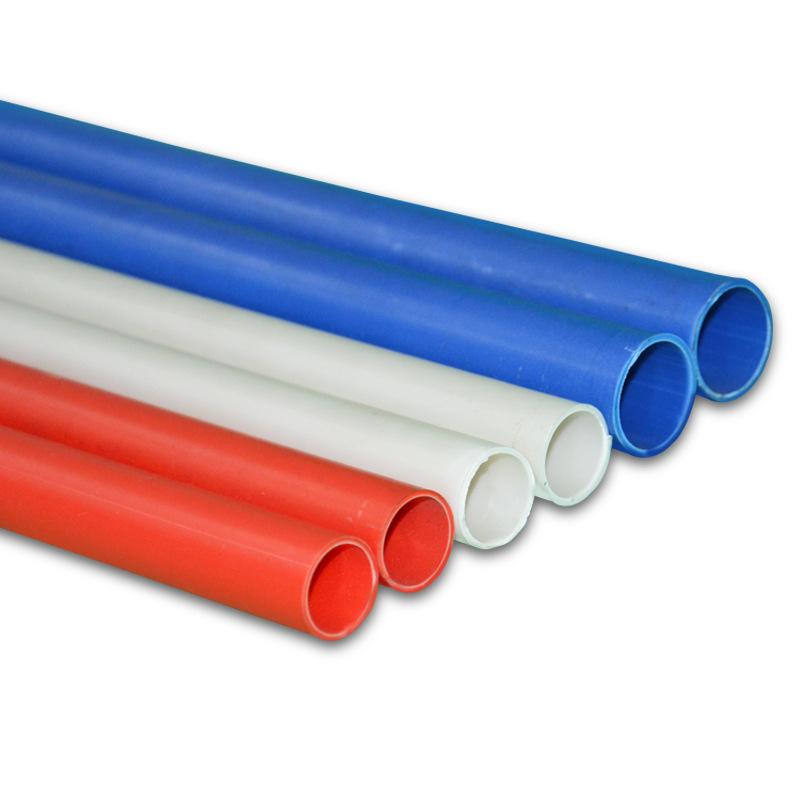

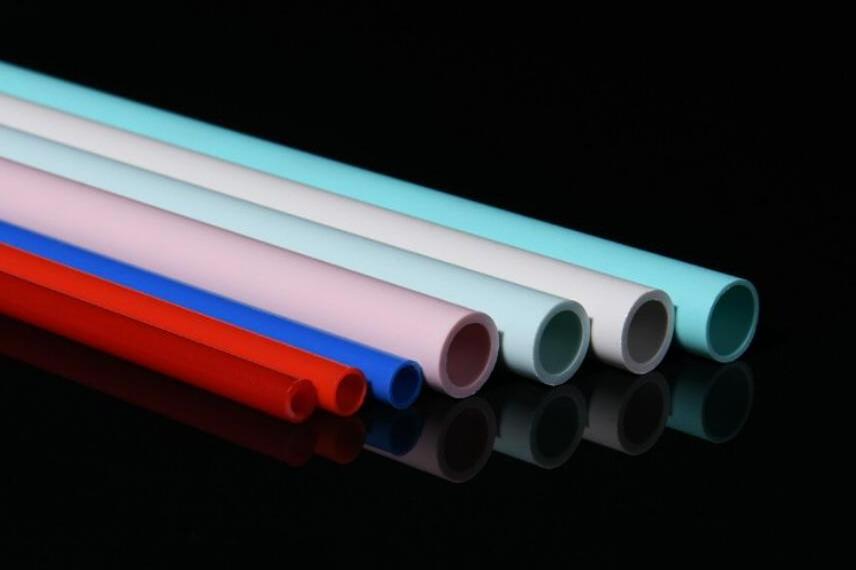

Color:

-

White

-

Application:

-

drainage system

-

Product name:

-

PVC Pipe

-

Size:

-

4-6

-

Certification:

-

ISO

-

MOQ:

-

100Meters

-

Advantage:

-

High Quaity

-

Lifespan:

-

50 Years Underground

-

Feature:

-

Corrosion Resistant

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

HAISHA

-

Model Number:

-

A

-

Specification:

-

D50/75/110/160/200

-

Length:

-

50-200

-

Standard:

-

GB/T5836.1-2018

-

Color:

-

White

-

Application:

-

drainage system

-

Product name:

-

PVC Pipe

-

Size:

-

4-6

-

Certification:

-

ISO

-

MOQ:

-

100Meters

-

Advantage:

-

High Quaity

-

Lifespan:

-

50 Years Underground

-

Feature:

-

Corrosion Resistant

Products Description

Specification

PVC-U Drainpipe have D40, D50, D75, D110, D160, D200.

PVC-U Spiral Silencer Pipe have three norms D75, D110, D160.

PVC-U Rainwater Pipe have four norms D50, D75, D110, D160.

PVC-U Insulated Electrical Sleeves have three models L/M/H and six norms dn16,20,25,32,40,50.

|

PVC-U Building Drainage Pipe Series

|

|

|

|

|

||||

|

Series

|

Drainpipe

|

Rainwater Pipe

|

Spiral Silencer Pipe

|

Electrical Sleeves(L/M/H)

|

||||

|

DN/MM

|

Thickness

|

Thickness

|

Thickness

|

Diameter

|

||||

|

40

|

2.0

|

/

|

/

|

dn16

|

||||

|

50

|

1.6/1.8/2.0

|

1.8

|

/

|

dn20

|

||||

|

75

|

1.8/1.9/2.0/2.3

|

1.9/2.3

|

2.3/4.0

|

dn25

|

||||

|

110

|

2.4/2.8/3.2/4.0

|

2.1/4.0

|

3.2/3.8/5.0

|

dn32

|

||||

|

160

|

2.8/3.2/4.0

|

2.8/4.0/5.0

|

4.0/6.0

|

dn40

|

||||

|

200

|

3.2/4.0/4.9

|

/

|

/

|

dn50

|

||||

Features.

Drainage, rainwater pipe series performance characteristics:

1. Excellent physical and chemical properties, chemical corrosion resistance, high impact strength, low fluid resistance, compared with the same diameter cast iron pipe flow rate increased by 30%.

2. Aging resistance, long service life, according to the Ministry of Construction, Fujian Province, trial pilot data show that the service life of 30-50 years, is the ideal material for building drainage, sewage.

3. Lightweight and durable, easy to install, can favorably speed up the project progress, reduce construction costs.

4. Saving construction costs, relative to the same specifications of the traditional cast iron pipe, can greatly reduce its overall cost.

5. The product is mainly white, beautiful color, bright and smooth, can make the environmental atmosphere within the building to produce a neat, relaxed sense of the times.

Spiral pipe performance characteristics:

1. Low cost: the product has a large drainage capacity. Therefore, it reduces the material cost, saves the installation cost such as labor, and can increase the indoor use area.

2. Reduce noise: water flow from the horizontal branch pipe into the vertical pipe or from above and below the flow, through the tee, four-way conduction, along the tube protruding spiral rib rotating down to reduce the collision of the water flow and irregular movement of the air and the pipe wall, standardize the direction of the fluid flow to reduce the impact of "water hammer", and tee at the tangent into the tangent to reduce water collision, thereby reducing the noise, and thus reducing the noise. Collision of water flow, thus reducing noise.

3. Safety guards: Because the spiral riser has good decompression performance, thus greatly improving the safety coefficient of high-rise building drainage pipe, but also reduces the possibility of the formation of a variety of reasons for the toilet appliance bubbling back to the wet.

4. Convenient installation and maintenance: there is no need to set up expansion joints, the horizontal riser can be dismantled, beautiful appearance, good seismic effect, easy and fast installation.

Application of PVC-U Pipe

PVC-U pipes, also known as unplasticized polyvinyl chloride pipes, find extensive applications across various industries and sectors. They are commonly employed in water supply and distribution systems for both potable and non-potable water, owing to their resistance to corrosion, low reactivity, and smooth internal surface that minimizes friction loss. Additionally, PVC-U pipes are widely utilized in drainage and sewerage systems due to their high strength, chemical resistance, and long-term durability, making them suitable for underground installations. In the agricultural sector, PVC-U pipes are frequently used for irrigation purposes, as they can withstand harsh environmental conditions and are resistant to chemical and biological degradation. Moreover, these pipes are employed in ventilation and ducting systems for air and fume extraction in industrial and commercial buildings. Their non-conductive properties also make them ideal for protecting electrical and telecommunication cables. Furthermore, PVC-U pipes are utilized in various industrial processes for the transportation of chemicals, acids, alkalis, and in water treatment systems. Overall, the versatility, durability, and chemical resistance of PVC-U pipes make them a popular choice for a wide range of applications in construction, infrastructure, and industrial settings.

Manufacturing Technique

Brief description of the production process:

The production process of PVC-U pipes involves several key steps:

1. Raw material preparation: The process begins with the preparation of raw materials, including PVC resin and additives such as stabilizers, plasticizers, and impact modifiers. These materials are carefully selected and mixed to achieve the desired properties.

2. Mixing and compounding: The raw materials are then mixed and compounded in a high-speed mixer to ensure uniform distribution of additives and to achieve the required material properties.

3. Extrusion: The compounded PVC-U material is then fed into an extruder, where it is heated and melted. The molten material is then forced through a die to form the shape of the pipe. During this process, the pipe is also cooled to ensure it maintains its shape and dimensions.

4. Sizing and cooling: The extruded pipe is passed through a sizing sleeve to give it the correct dimensions and shape. It is then rapidly cooled to solidify the material.

5. Cutting and storage: Once the pipe has been cooled and solidified, it is cut into specific lengths and undergoes quality

control checks to ensure it meets the required standards. The finished pipes are then stored and prepared for distribution.

Throughout the production process, strict quality control measures are implemented to ensure that the PVC-U pipes meet the necessary standards for strength, durability, and performance. This meticulous production process results in high-quality PVC-U pipes that are suitable for a wide range of applications in various industries and sectors.

1. Raw material preparation: The process begins with the preparation of raw materials, including PVC resin and additives such as stabilizers, plasticizers, and impact modifiers. These materials are carefully selected and mixed to achieve the desired properties.

2. Mixing and compounding: The raw materials are then mixed and compounded in a high-speed mixer to ensure uniform distribution of additives and to achieve the required material properties.

3. Extrusion: The compounded PVC-U material is then fed into an extruder, where it is heated and melted. The molten material is then forced through a die to form the shape of the pipe. During this process, the pipe is also cooled to ensure it maintains its shape and dimensions.

4. Sizing and cooling: The extruded pipe is passed through a sizing sleeve to give it the correct dimensions and shape. It is then rapidly cooled to solidify the material.

5. Cutting and storage: Once the pipe has been cooled and solidified, it is cut into specific lengths and undergoes quality

control checks to ensure it meets the required standards. The finished pipes are then stored and prepared for distribution.

Throughout the production process, strict quality control measures are implemented to ensure that the PVC-U pipes meet the necessary standards for strength, durability, and performance. This meticulous production process results in high-quality PVC-U pipes that are suitable for a wide range of applications in various industries and sectors.

Details Images

Hot Searches