Hydraulic pressure molding technology is adopted by this machine, and the pressure can arrive at 31 MPa, so the blocks produced are of good quality, large density and high strength.

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FULANG

-

Voltage:

-

Adapt to local voltage

-

Dimension(L*W*H):

-

3700*2100*2300mm

-

Weight (KG):

-

3000 kg

-

Product Name:

-

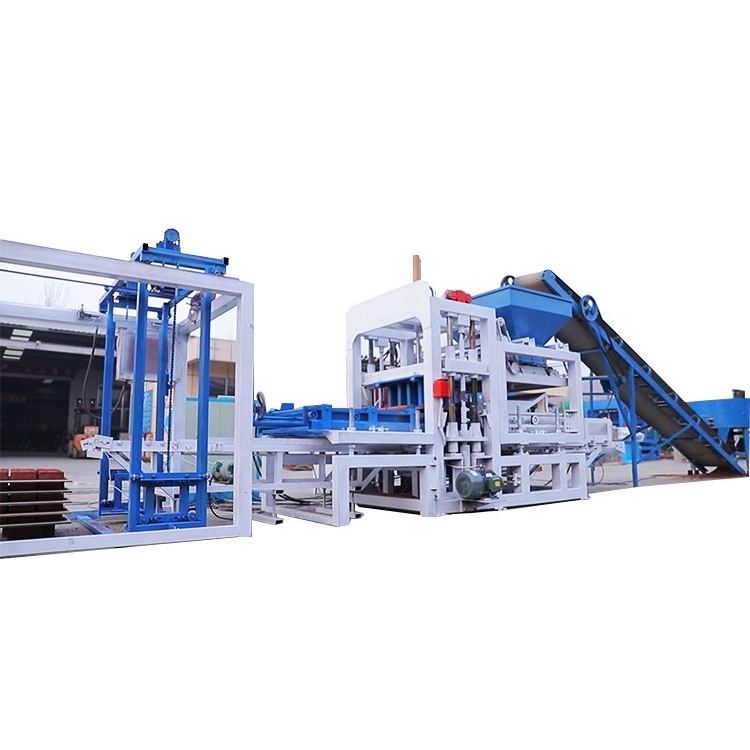

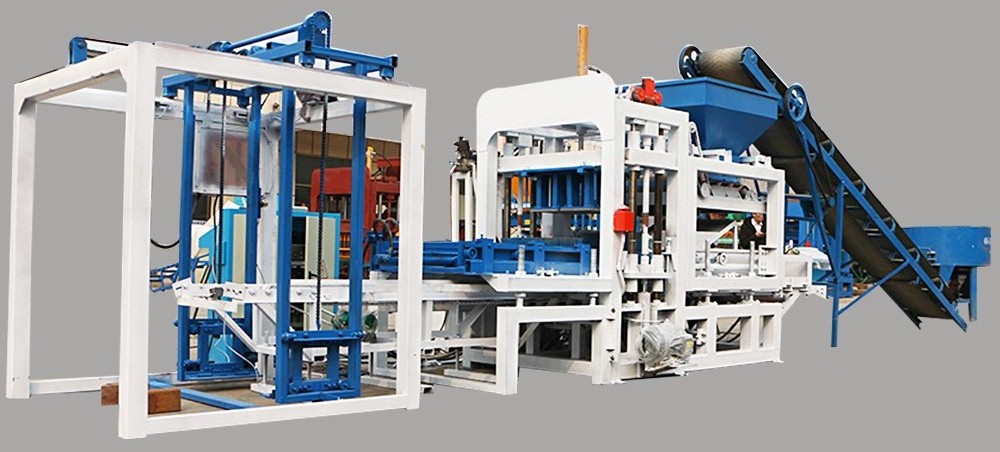

QTY4-25 used automatic concrete stone block brick making machine

-

Weight:

-

3.0T

-

Molding cycle:

-

15-20s

-

Vibration force:

-

35.5KN

-

Pallet size:

-

850*550*30mm

-

Mixer:

-

JQ500

-

Workshop:

-

60㎡

-

Raw material:

-

Cement/Concrete/Crushed stone/Sand/Fly ash

-

Products:

-

hollow blocks,solid blocks,pavers,curbstones

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

3456-23040Pcs/8Hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FULANG

-

Voltage:

-

Adapt to local voltage

-

Dimension(L*W*H):

-

3700*2100*2300mm

-

Weight (KG):

-

3000 kg

-

Product Name:

-

QTY4-25 used automatic concrete stone block brick making machine

-

Weight:

-

3.0T

-

Molding cycle:

-

15-20s

-

Vibration force:

-

35.5KN

-

Pallet size:

-

850*550*30mm

-

Mixer:

-

JQ500

-

Workshop:

-

60㎡

-

Raw material:

-

Cement/Concrete/Crushed stone/Sand/Fly ash

-

Products:

-

hollow blocks,solid blocks,pavers,curbstones

QT4-18 Automatic Concrete paver Block Brick Making Machine

■ Main Features

1.QT4-18 concrete block making machine can produce various hollow blocks, solid blocks and pavers by changing moulds.

2.Hydraulic pressure molding technology is adopted by this machine, so the brick machine has more stable and high-efficiency working status and the bricks produced are of better quality, larger density and higher strength.

3.Precise line cutting technology and carburizing treatment technology assure longer mould life span.

4.All materials and spare parts selected according to international CE standard to assure whole line stable running.

■

Technical Parameters

|

Dimension

|

|

3700*2100*2300mm

|

|

||

|

Host Machine Power

|

|

16.35KW

|

|

||

|

Mould Period

|

|

20s

|

|

||

|

Vibration Force

|

|

35.5KN

|

|

||

|

Weight of Host Machine

|

|

3.0T

|

|

||

|

Raw Materials

|

|

Cement /Concrete /Sand /Fly ash /Crushed Stone

|

|

||

■

Theoretical Production Capacity

|

Size(LxWxH)

|

Pcs/Mould

|

Pcs/Hr

|

Pcs/8Hr

|

|

400x100x200mm

|

7

|

1008

|

8064

|

|

400x150x200mm

|

5

|

720

|

5760

|

|

400x200x200mm

|

4

|

576

|

4608

|

|

400x250x200mm

|

3

|

432

|

3456

|

|

230x110x70mm

|

20

|

2880

|

23040

|

Hydraulic System

Mould

With the best steel as raw material, we are elaborately manufactured by advanced wire cutting and carburizing heat treatment process, and have strong wear resistance

.

PLC control system

Select original Mitsubishi PLC control system and Japan Omoron or France Schneider switches to assure stable and high-efficiency working status of the machine

.

QT4-18 concrete brick making machine can produce various hollow blocks,solid blocks and pavers by changing moulds. The following bricks are some common brick types.Also we can customize brick moulds for you based on your requirements.

FULANG Machinery Group Co. Ltd is a Chinese manufacturer of dedicated machinery for construction blocks and panels. Our company offers complete production lines for premium building components such as the autoclaved sand -lime brick, autoclaved aerated concrete brick, and autoclaved aerated concern autoclaved lightweight concrete panel. Additional, we provide various types of pressure vessels and block-making machines. By choosing FULANG,customers can enjoy professional benefits with our dedicated services for design, install, layout planning, technology transfer,and production guidance.

With 20 years development , our products have been sold to more than 80 countries.Till now, about 1200 customers have visited our factory. Also we have engineers stay abroad to help you install the machines and training your workers at your side

.

☎ The FAQ

☛1.Q: What kind of payment terms do we accept?

A:T/T and L/C are common for us. Other ways are ok by negotiation.

☛

2.Q:How about your Production time ?

A: Normally 10-15 days after your deposit.

☛3.Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year.

☛4.Q: Do you provide after-sale service?

A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

☎ Our Service

★Pre-Sales

1.Perfect 7*24 hours inquiry and professional consulting services.

2.Visit our factory anytime.

★Sale

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

★After-Sales

1.Warranty period : 2 YEAR after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skill support the whole using life.