- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Mesure

-

Dimension(L*W*H):

-

2200*2200*2200

-

Weight:

-

5555 KG

-

After-sales Service Provided:

-

Online Support

-

Product name:

-

Bottle Filling Capping

-

Function:

-

Bottle Washing Filling Capping

-

Local Service Location:

-

Indonesia

-

Name:

-

Bottle Liquid Filling Machine

-

Usage:

-

Beverage Packaging

-

Bottle type:

-

PET Plastic Bottle

-

After Warranty Service:

-

Non - Man-made Damaged Parts

-

Keywords:

-

Fillng Machine

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 20000BPH, 16000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Milk, Water, Juice

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Mesure

-

Dimension(L*W*H):

-

2200*2200*2200

-

Weight:

-

5555 KG

-

After-sales Service Provided:

-

Online Support

-

Product name:

-

Bottle Filling Capping

-

Function:

-

Bottle Washing Filling Capping

-

Local Service Location:

-

Indonesia

-

Name:

-

Bottle Liquid Filling Machine

-

Usage:

-

Beverage Packaging

-

Bottle type:

-

PET Plastic Bottle

-

After Warranty Service:

-

Non - Man-made Damaged Parts

-

Keywords:

-

Fillng Machine

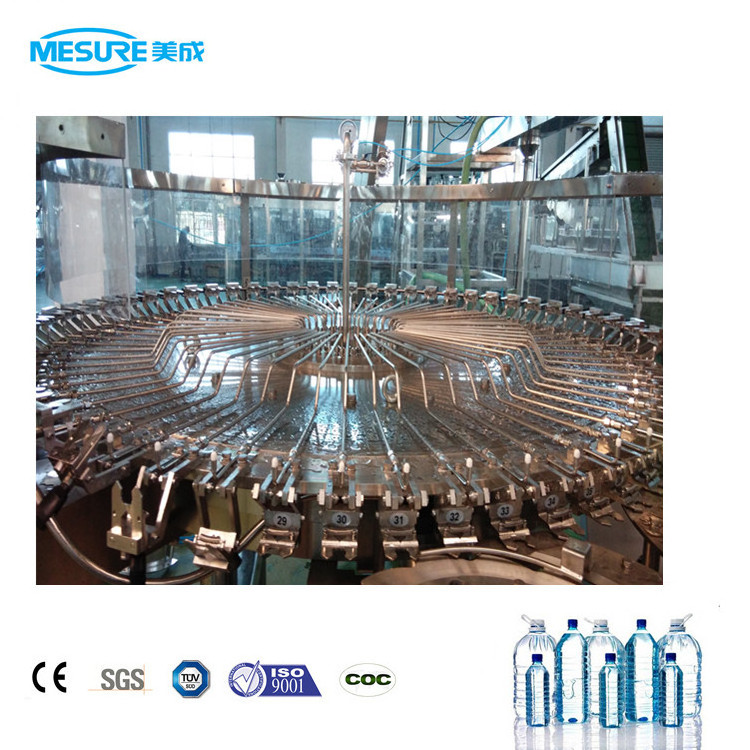

Product Application

This series of mineral water filling machine are applied to the production of pure water, mineral water, with optional capacity from 3,000 to 40,000BPH. The washing, filling and capping will be finished just by this one machine.

It is very convenient to change bottle size by means of advanced bottle conveying technology-bottle neck clamping & bottle suspending technology.

Main Features:

1. Washing,filling,capping can be carried out on the same machine. The design of the machine is scientific and reasonable.

2. The water filling machine appearance is beautiful and the function is complete. The operation and maintenance is convenient.

3. The water filling machine adopts advanced technology and normal pressure filling valves, with high filling precision. The speed of filling is fast and the liquid amount is controlled accurately, with same filling level.

4. The water filling machine filling device can be stopped automatically when there is no bottle or bottles are damaged.

5. Pneumatic value and damped gears are used for bottle conveying, the noise is low and the whole machine runs smoothly.

6. The magnetic torque is used for screw capping.The power of screw capping can be adjusted without steps. The power of the screw capping can also be fixed. The caps can not be damaged, the capping is reliable.

|

Model

|

CGN

14-12-5

|

CGN

18-18-6 |

CGN

24-24-8 |

CGN

32-32-10 |

CGN

40-40-15 |

CGN

50-50-20 |

CGN

60-60-20 |

CGN

72-72-22 |

|||||||

|

0.5L(Per Hour)

Capacity |

3000~

4000BPH |

5000~

6000 BPH |

12000

BPH |

18000~

20000 BPH |

24000~26000

BPH |

30000~

33000 BPH |

36000~

38000 BPH |

40000~

42000 BPH |

|||||||

|

Bottle

Suitable |

PET round or square

|

|

|

|

|

|

|

|

|||||||

|

Bottle

diameter |

50mm~97mm

|

|

|

|

|

|

|

|

|||||||

|

Bottle

height

|

150mm~320mm

|

|

|

|

|

|

|

|

|||||||

|

Compressed air pressure

|

0.5~1Mpa

|

|

|

|

|

|

|

|

|||||||

|

Washing

Mdeium

|

Aseptic Water

|

|

|

|

|

|

|

|

|||||||

|

Washing

Water's Pressure |

0.2~0.25Mpa

|

|

|

|

|

|

|

|

|||||||

|

Total

Power

<kw>

|

4.5

|

4.5

|

5.3

|

7.2

|

10.5

|

13.7

|

14.5

|

16.3

|

|||||||

|

Weight

<kg> |

3500

|

4000

|

5600

|

14000

|

16000

|

19000

|

23000

|

26000

|

|||||||

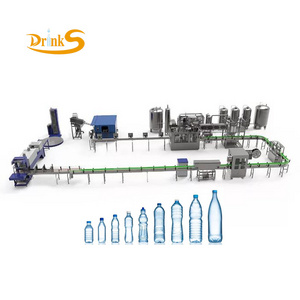

Main Composition

Drink Water Flow Chart

1) Bottle neck clamping which will not damage the bottle mouth;

2) Different bottles can be used in same machine (the bottle neck should be the same) by changing some parts;

3) Less area to place the machine

4) Low cost in investment

5) Low energy consumption

Installation and commissioning

After the equipments arrived buyer's workshop, the buyer should take it's place for each equipment according to the supplied layout; the seller will send the experienced technician to guide the installation and debugging and trail production, and fulfil the designed capability within the designed time.

Training

The seller will supply technical training to the buyer. The training is includes: equipment structure and maintenance, control and operation. After training, the technicians of the buyer will grasp relevant operation and maintenance skills, and could adjust the technologies more skilled, and can deal with all kinds of malfunction in time.

After-sales service

1) After qualified of the equipment, the seller will supply one year guarantee, control system one year guarantee, free charge for wearing parts, and other spare parts with cost price. Within guarantee period, the technicians who accepted training should strictly obey the requirements asked by the seller to operate the equipments and maintenance, to find the common malfunctions and fault clearing in time; if the technicians of the buyer couldn't solve the problems themselves, the after-sales department will supply long range guide service by phone; if relevant measurements couldn't solve the problems, the seller will send the technicians to the buyer factory, clear the fault or relevant technical problems on site, the charges will reference to the installation and debugging charges.

2) After guaranteed, the seller will supply widely favorable technical support, after-sales service for the lifetime: favorable price for the wearing parts and other spare parts.