Original: Guangdong,China (mainland)

This is an uncoiler system with hytraulic epuipment or motor epuipment, which can supply the coil for the flowing flow.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Liding

-

Voltage:

-

380V 3phases 50HZ

-

Power:

-

22kw

-

Dimension(L*W*H):

-

About 7m*1m*1.4m

-

Weight:

-

8000

-

Product name:

-

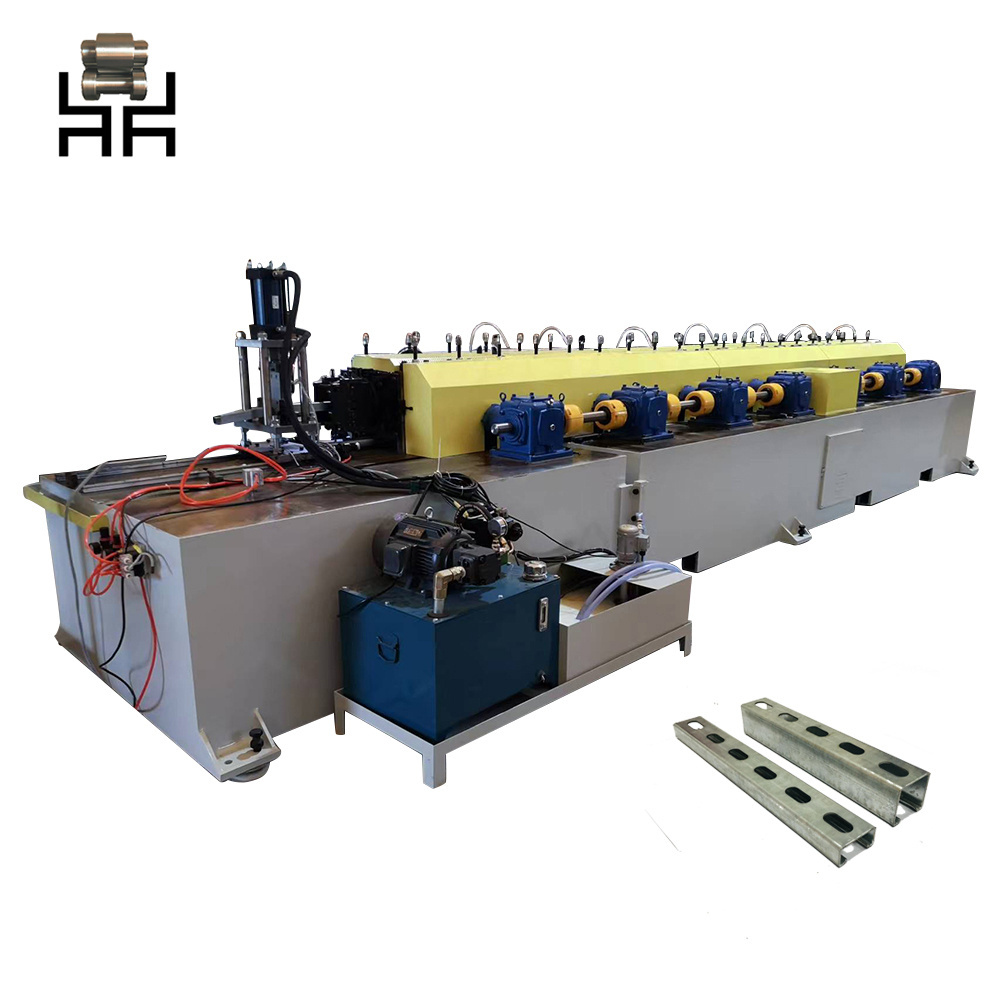

Solar Bracket C channel roll forming machine

-

Keywords:

-

purlin roll forming Making Machine

-

Selling point:

-

High-accuracy

-

Punching:

-

High-speed punching

-

Application:

-

C Solar Strut

-

After-sales Service Provided:

-

Online support, Free spare parts, commissioning and training

-

Operation:

-

Automatic

-

Electric Control system:

-

Fully Automatic PLC(imported Brand),transducer, touch panel

-

Material:

-

Steel Galvanized Plate

-

Profile design:

-

custom

Quick Details

-

Work Pressure:

-

16Mpa

-

Production Capacity:

-

6m/min

-

Place of Origin:

-

Guangdong China

-

Brand Name:

-

Liding

-

Voltage:

-

380V 3phases 50HZ

-

Power:

-

22kw

-

Dimension(L*W*H):

-

About 7m*1m*1.4m

-

Weight:

-

8000

-

Product name:

-

Solar Bracket C channel roll forming machine

-

Keywords:

-

purlin roll forming Making Machine

-

Selling point:

-

High-accuracy

-

Punching:

-

High-speed punching

-

Application:

-

C Solar Strut

-

After-sales Service Provided:

-

Online support, Free spare parts, commissioning and training

-

Operation:

-

Automatic

-

Electric Control system:

-

Fully Automatic PLC(imported Brand),transducer, touch panel

-

Material:

-

Steel Galvanized Plate

-

Profile design:

-

custom

Products Description

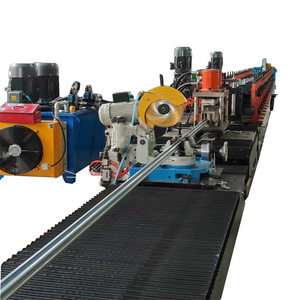

Solar Bracket C channel Roll Forming Machine

The fully automatic metal strut framing channel production line is a special production line equipment specially designed for quality metal strut framing systems manufacturers .

* It is widely used especially in solar panel supports .

Customers can choose the appropriate equipment according to their own and market demand.

Customers can choose the appropriate equipment according to their own and market demand.

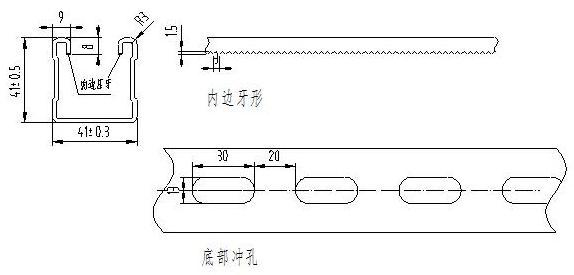

Product Specifications

Solar photovoltaic bracket roll forming machine details:

Solar photovoltaic bracket roll forming machine details:

Feeding material: galvanized steel coil

Thickness of the plate:1.5-3.0mm

Diameter of the axle & Material :Φ58mm, 45# steel

Thickness of the plate:1.5-3.0mm

Diameter of the axle & Material :Φ58mm, 45# steel

Bearing

Material

:NJ210E

Rolling stages:21stages

Rolling stages:21stages

Rolling

Material :

Cr12MoV

Productivity: 6m/min

Total power: 22 kw machine motor

Voltage:380V 50Hz 3phase

Side board:30mm

Cutting blade: Cr12MoV with heat treatment

Productivity: 6m/min

Total power: 22 kw machine motor

Voltage:380V 50Hz 3phase

Side board:30mm

Cutting blade: Cr12MoV with heat treatment

Main drive reduction gearbox: BWD4

Transmission: Chain and gearbox steering transmission

|

No

|

Item

|

Data

|

|

1

|

Electric Decoiler

|

2 Ton

|

|

2

|

Servo feeder

|

1 set

|

|

3

|

Hydraulic punch modular

|

2 Stations,with 2 mold

|

|

4

|

Roll Forming Machine

|

8 Ton

|

|

5

|

Hydraulic cutting modular

|

1 Station,with 1 mold

|

|

6

|

Run Out Table

|

4 m

|

|

7

|

PLC controling

|

PLC control system with touch screen

|

Producing process

Decoiling

& Leveling

→Servo Feeding &

Punching

→ Roll forming&Straightening → Cutting→Run-out table

Details Images

20 years of production experience to provide customers with solutions

Provide customers with equipment, photovoltaic project installation, and provide photovoltaic bracket profiles

Solar photovoltaic bracket

production line

The complete production process is the basis for your choice of machine

Decoiler

1.Material width: 200mm.

2. Material thickness: 3.0mm.

3.Servo motor:AC1.8KW.

4. Feeding speed: 10m/min.

1. Feeding material: galvanized plate

2. Material thickness:1.5-3.0mm

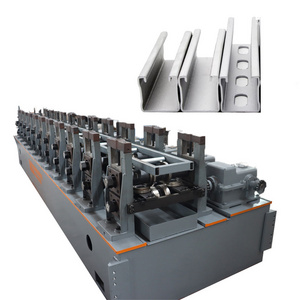

3. Machine can produce 41*21, 41*41 two kinds of specifications, change specifications by lifting forming module

4. Main motor power: 22kw (the total power of two motors is 22kw).

5. Forming speed: 6mm/min.

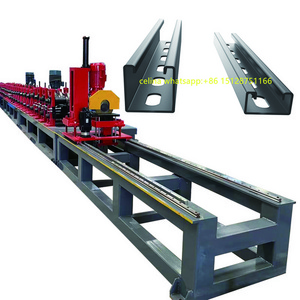

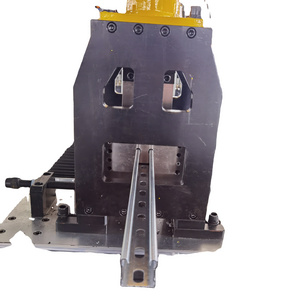

Hydraulic cutting system

Original: Guangdong, China (mainland)

1. with one set of hydraulic system device

2. with two sets of mould cutting.

3. Motor power: 4 kW.

4. Adopt the oil cylinder control cutting off method.

5. Adopt non-stop cylinder jack cutting off method

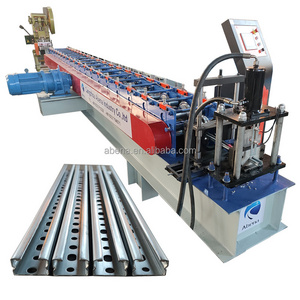

1.Voltage: 380 V, 50 Hz, 3Phase

2. Punching automatic length measurement: servo motor

3. Automatic measurement: Encoder

4. Length and quantity controlled by PLC. The machine will automatically cut off the length and stop when the required quantity is reached.

5. Control panel: push button switch, touch screen

Hot Searches