- Product Details

- {{item.text}}

Quick Details

-

Name:

-

Tube shrinking machine

-

weight:

-

900kg

-

size:

-

800*650*900mm

-

Spindle speed:

-

175

-

Molding time:

-

5-30

-

Maximum processing length:

-

400mm

-

Machine model:

-

XS-40Z

-

Materials that can be processed:

-

metal

-

application:

-

Round tube

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SHIGAN

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Name:

-

Tube shrinking machine

-

weight:

-

900kg

-

size:

-

800*650*900mm

-

Spindle speed:

-

175

-

Molding time:

-

5-30

-

Maximum processing length:

-

400mm

-

Machine model:

-

XS-40Z

-

Materials that can be processed:

-

metal

-

application:

-

Round tube

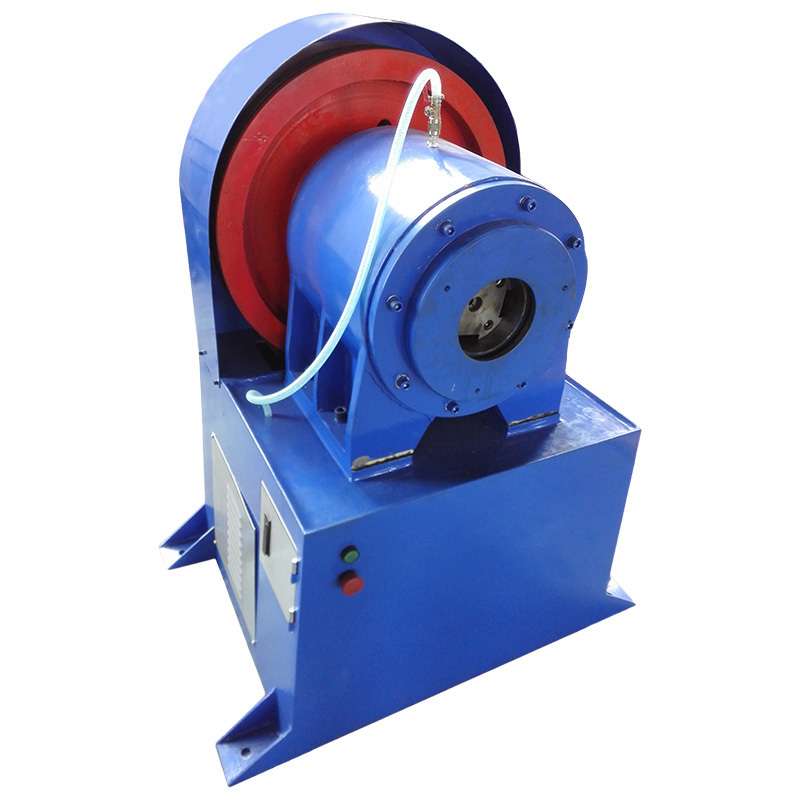

Taper tube shrinking machine tube end forming machine for round bar or steel tube

When the machine is working, it is forbidden to enter its action area;

The operator must stand within reach of the emergency stop switch;

This unit must be operated by a person;

When the machine is faulty, please turn off the power;

Keep the machine and environment clean;

For safety, please turn off the power when installing the mold;

Place the machine on a sturdy floor and calibrate the level to make the machine more stable;

Check the motor steering, such as steering error, adjust the power wiring;

When using the button, tap gently to prevent the use of hard objects to touch.

The cold forging method is used to forge and lengthen the pipe into a cylinder or a cone.

Closed circuit

The circulation lubrication system ensures that the machine runs normally for a long time.

Different shapes and sizes and workpieces can be machined with the corresponding mold. The workpiece is bright, round and has high strength.

FAQ

|

Choose us Q: How to quickly choose the most suitable product for you? A: You can check it on the product page, or contact customer service at +8618021646346 to tell the following details: What machine do you need? The size, thickness, material, and processing requirements of the workpiece, it is best to have a drawing of the workpiece, and we will provide a more professional machine according to your requirements. |

|

Payment method Q: What are your payment terms? A: We support T/T, L/C, etc. TT, 30% in advance, and the balance 70% before shipment. |

|

Delivery guarantee Q: What is the delivery time? A: Usually in stock, if you need to order fixtures and molds, we usually complete it within 7-15 working days. For customized products, please contact customer service to determine the exact time. |

|

Use guarantee Q: When I bought this machine, I didn't know how to use it. what do I do? A: We will send English manuals, installation and operation videos with the equipment. If you still have questions, we can talk via phone, Whatsapp, WeChat and email. |

|

Quality assurance Q: How to ensure quality? A: We have factories. We are industry experts and have been operating for more than 10 years. We always adhere to the policy of "high quality, all-round service". |

|

Warranty service Q: How long is the warranty period? A: Within one year from the date of leaving the factory, if the part fails or is damaged (Due to quality problems, wearing parts are excluded), our company provides these parts for free. |

|

Company visit Q: How do we reach your company? A: Our company is located in Zhangjiagang City, Jiangsu Province, near Shanghai. You can fly directly to PVG Airport or Shanghai Hongqiao Airport. Welcome to visit our company. |