- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw Material:

-

Steel Bar

-

Power:

-

Hydraulic

-

Name:

-

Hydraulic Press Brake

-

Type:

-

Hydraulic Bending Tools

-

Usage:

-

Metal Sheet Rolling Cutting Bending

-

Application:

-

Stainless Steel Strip Bending

-

Material:

-

Q235

-

Warranty:

-

2 Years

-

Color:

-

Customized

-

Keyword:

-

Brake Press Machine

-

Function:

-

Bending Alimunum Steel

-

Available bend profiles:

-

Angle Bar

-

Model Number:

-

WC67Y

-

Certification:

-

CE/ISO

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Aoxuan

-

Machine Type:

-

Press Brake

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw Material:

-

Steel Bar

-

Power:

-

Hydraulic

-

Name:

-

Hydraulic Press Brake

-

Type:

-

Hydraulic Bending Tools

-

Usage:

-

Metal Sheet Rolling Cutting Bending

-

Application:

-

Stainless Steel Strip Bending

-

Material:

-

Q235

-

Warranty:

-

2 Years

-

Color:

-

Customized

-

Keyword:

-

Brake Press Machine

-

Function:

-

Bending Alimunum Steel

-

Available bend profiles:

-

Angle Bar

-

Model Number:

-

WC67Y

-

Certification:

-

CE/ISO

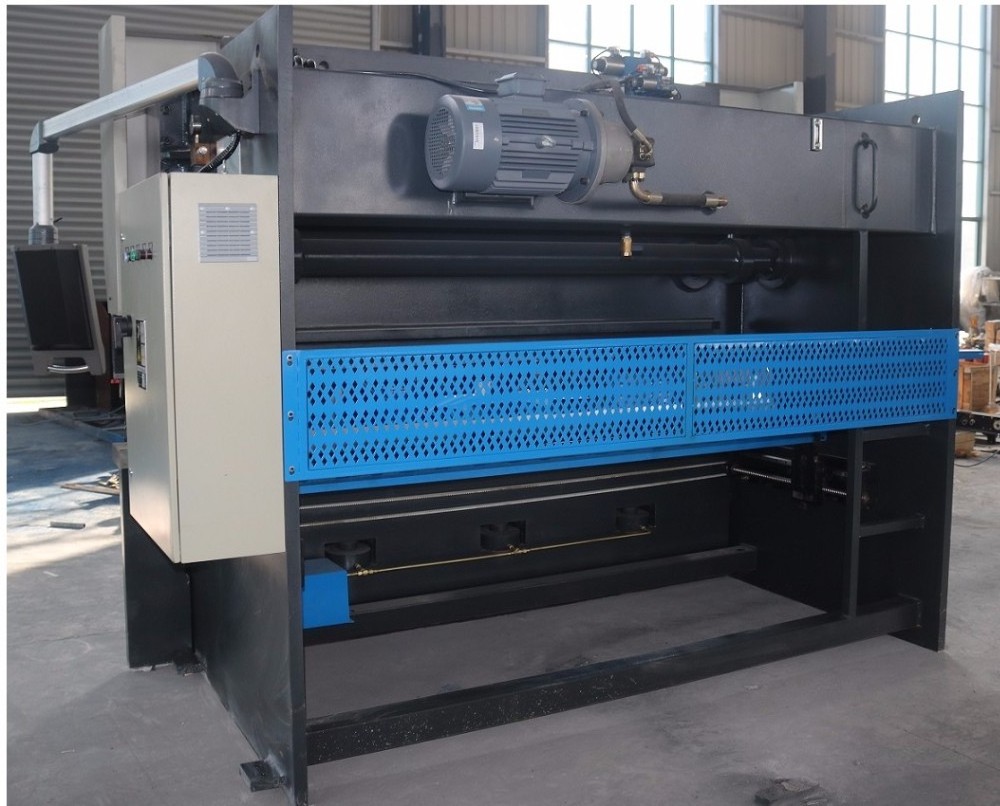

The whole structure:

1. Steel plate welded structure, hydraulic transmission, accumulator return, holistic processed, vibrating to

eliminate stress, high strength and good rigidity.

2. Mechanical torque system makes sure the synchronization of cylinders.

3. The stroke of slider and back gauge is adjusted automatically by double servo motors or transducer, and showed on

CNC Mechanical torque or NC control panel.

4. Slanting wedges can be chosen to install on the top dies which can be adjusted by hands or automatically.

Hydraulic compensation system is installed under the worktable.

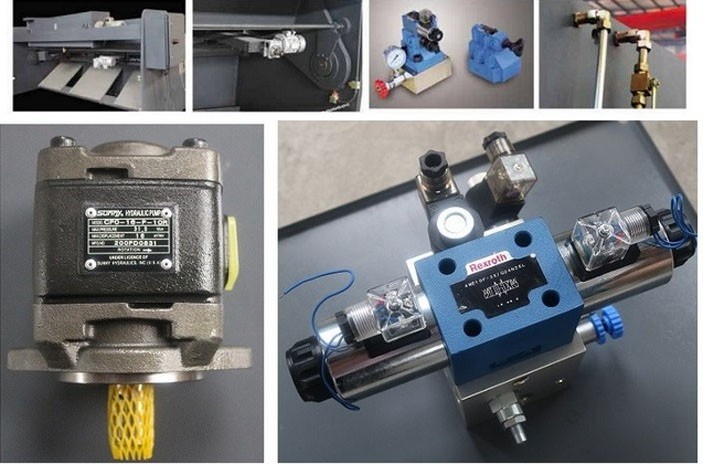

Hydraulic system:

1. Hydraulic control system by BOSCH-REXROTH Germany or FIRST America.

2. Oil seals by Japanese, NOK.

3. Overload & overflow protection to ensure there is no leakage and protect hydraulic system, and the oil level can be

read directly.

Servo motorized back gauge:

1.CNC Back gauge system with X axis by AC servo motor driven ball screw shafts and on linear bearings

2. Back gauge has well enough mechanical strength and rigidity with tank-type gauge structure.

3. High-precision ball screw and linear guide-way. Particular finger-stop design, enlarge the range of back gauge.

Electrical parts and protection device:

1. Schneider or Siemens Low-voltage apparatus. In accordance with international standards, reliable safety, long life,

good anti-interference ability, a radiation unit is fitted in electrical cabinet.

2. Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,

easy to operate.

3. Light screen protection or Laser protection are optional.

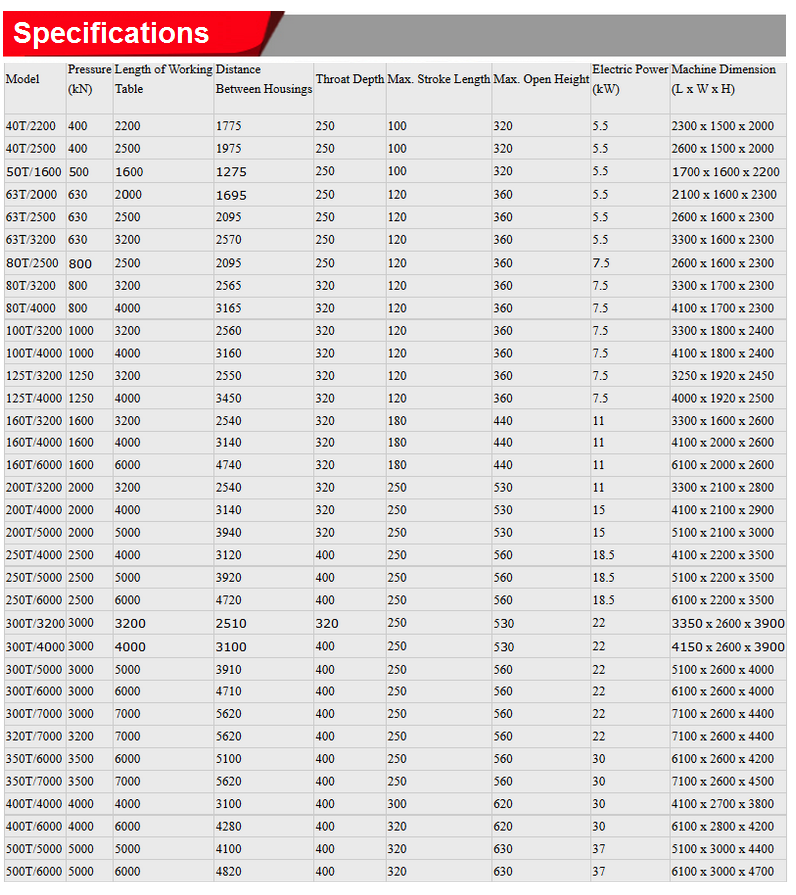

Technical parameters

Standard Equipment:

1. 3 & 4- axis Delem DA52s programming mode CNC control.

2. Full synchronisation of Y1 + Y2 axes with proportional hydraulic valve system and constant monitoring by CNC system to +/- 0.01mm accuracy

3. High precision linear scales for measurement of stroke depth mounted on side frames rather than top beam to prevent any distortion in accuracy as beam comes under load

4. CNC-controlled X & R-axis as standard ballscrew backgauge with servo drive motors.

5. Light guards

6. Two micrometric backgauge finger-stops with lateral adjustment

7. Steel mono-block construction

8. Polished chrome plated and ground cylinders

9. Long stroke and large open height dimensions

10. High approach and return speeds for production bending.

11. Euro style quick release top tool holders with intermediaries including wedges for crowning

12. 88 degree sectionalised goose neck top tool

13. 4 way sectionalised multi vee bottom tool

14. Double footswitch control and pendant type control arm.

15. AKAS laser tooling guards

16. Electrically interlocked side guards ;

17. Electrically interlocked read access door

18. 2 sliding front support arms with linear guide rails for lateral adjustment and hand wheel for height adjustment, 1000mm long from centre of bottom tool vee.

19. Side guard is standard meeting CE regulations.