- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Aircraft blade

-

Product name:

-

diamond roller dressing for precision parts for aircraft engines

-

USE:

-

dressing

-

Material:

-

diamond

-

Shape:

-

Round Disc

-

Advantage:

-

High Working Efficiency

-

application:

-

precision parts for construction turbine blades for aircraft engines

-

Size:

-

according to your needs

-

MOQ:

-

5pcs

-

Package:

-

Standard Package

-

Sample:

-

Availble

Quick Details

-

Type:

-

aircraft turbine blades

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SAISU

-

Model Number:

-

Aircraft blade

-

Product name:

-

diamond roller dressing for precision parts for aircraft engines

-

USE:

-

dressing

-

Material:

-

diamond

-

Shape:

-

Round Disc

-

Advantage:

-

High Working Efficiency

-

application:

-

precision parts for construction turbine blades for aircraft engines

-

Size:

-

according to your needs

-

MOQ:

-

5pcs

-

Package:

-

Standard Package

-

Sample:

-

Availble

Products Description

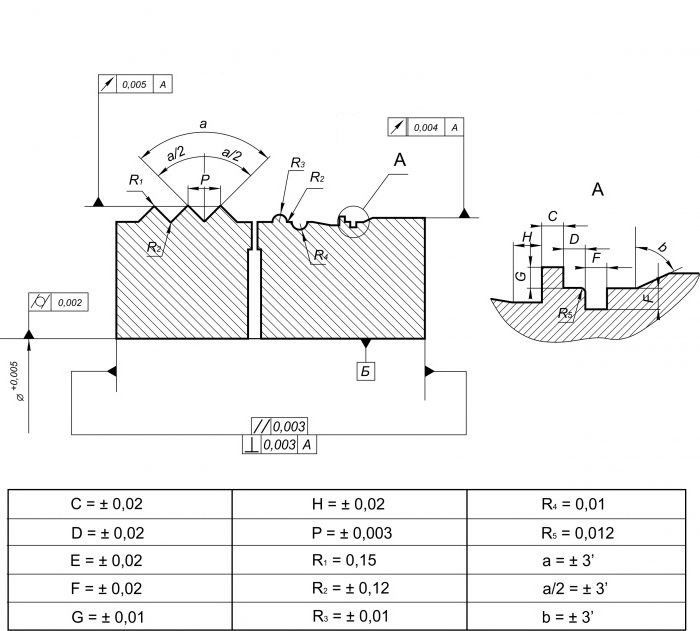

Diamond profile dressing rollers are an integral part of modern grinding technology and are mainly used in serial and mass production. Diamond rollers are used for dressing of abrasive wheels.With the help of diamond rollers, a copy of the profile of the required part is created on the surface of the working abrasive wheel. Then the abrasive wheel transfers this profile to the workpiece. At the same time, diamond rollers allow to combine several processing transitions at once, including turning, milling and preliminary grinding.

Advantages of using diamond profile dressing rollers:

Designed to form the surface of the abrasive wheel in the shortest possible time

Profiling the surface of an abrasive wheel in one operation

Provides high accuracy even when forming very complex profiles

The production program of CHINA SAISU DIAMOND TOOLS includes the production of diamond rollers which are used for:- crankshaft processing;

– processing of ball pins;

– grinding of piston rings;

– valve handling;

– screw tap/Drill bit grinding;

– Guide rail slide grinding;

– Ball screw grinding;

– manufacturing of turbine blades;

– manufacturing of cogwheels;

– manufacturing of threaded connections;

– manufacturing of details of the bearing industry.

Each dressing roller is accompanied by a measurement protocol according to the customer’s requirements,

as well as a control sample of the roller profile.

Hot Searches