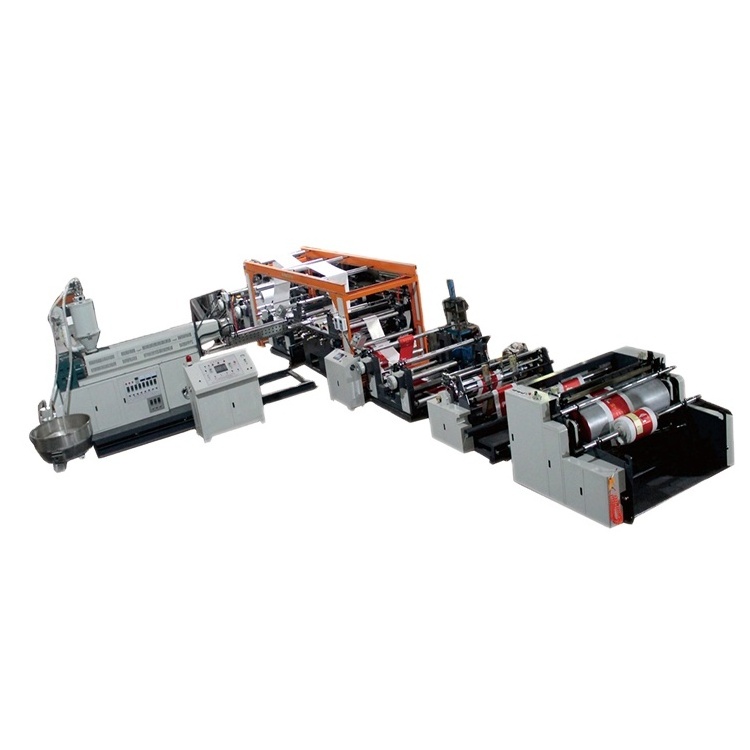

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

13800*6000*2600

-

Weight:

-

4500 KG

-

Product name:

-

Coating lamination machine

-

Function:

-

Bag making

-

Usage:

-

Film mulching

-

Keywords:

-

Coating

-

After Warranty Service 1:

-

Video technical support

-

After Warranty Service 2:

-

Online support

-

After Warranty Service 3:

-

Spare parts

-

After Warranty Service 4:

-

Field maintenance and repair service

-

Local Service Location:

-

None

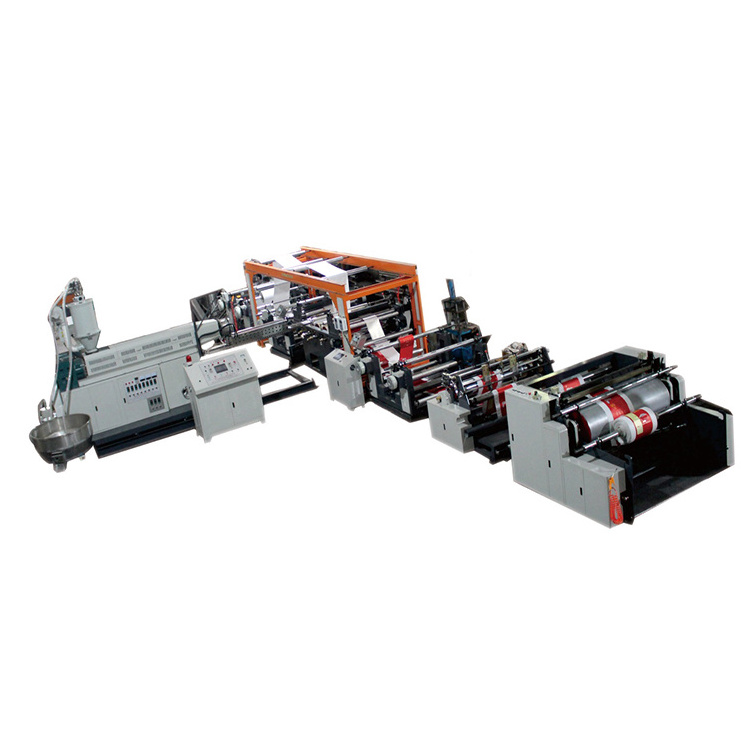

Quick Details

-

Voltage:

-

220/380/440

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

zhuding

-

Dimension(L*W*H):

-

13800*6000*2600

-

Weight:

-

4500 KG

-

Product name:

-

Coating lamination machine

-

Function:

-

Bag making

-

Usage:

-

Film mulching

-

Keywords:

-

Coating

-

After Warranty Service 1:

-

Video technical support

-

After Warranty Service 2:

-

Online support

-

After Warranty Service 3:

-

Spare parts

-

After Warranty Service 4:

-

Field maintenance and repair service

-

Local Service Location:

-

None

Banner

Product Description

Performance and Characteristics

(1)This Non woven fabric laminating machinemaking use of the good adhesive property ofpolypropylene & polyethylene at

meltingstatusachine adheres and aminat espaper or color-printed OPP &CPP fiim to Nonwoven fabric, The extruder with helical gearreducersteel adoptsautomat ic temperature-control system to ad justmelting temperature, the screw and cylinderare made of 38CRMOAIA alloy steel and donetreatment of nitrogenation.

(2)The double-die cando single or double-face coating, width ofcoating &laminating can be regulated, ancontrol coating thickned laminatingspeed, autom t ica I I y Autom a t ic edgcutting, edge-blowing, cutting-off and windingdevices are applied.

(3)This machine has the functions of fully automatic material receiving and refuelling, PLC control system, fully automatic weight control system, man-machine operation interface, and it is a high-quality supply in the same industry.

meltingstatusachine adheres and aminat espaper or color-printed OPP &CPP fiim to Nonwoven fabric, The extruder with helical gearreducersteel adoptsautomat ic temperature-control system to ad justmelting temperature, the screw and cylinderare made of 38CRMOAIA alloy steel and donetreatment of nitrogenation.

(2)The double-die cando single or double-face coating, width ofcoating &laminating can be regulated, ancontrol coating thickned laminatingspeed, autom t ica I I y Autom a t ic edgcutting, edge-blowing, cutting-off and windingdevices are applied.

(3)This machine has the functions of fully automatic material receiving and refuelling, PLC control system, fully automatic weight control system, man-machine operation interface, and it is a high-quality supply in the same industry.

|

Type/Item

|

Diameter of extruder screw

|

L/D ratio of screw

|

Number of Die

|

Width of Die

|

Total power(kw)

|

Power of extruder motor(kw)

|

Weight

|

|

ZD-FMF 105 / 1000B

|

105

|

28:1

|

2

|

1000

|

58

|

18.5

|

5500kg

|

|

ZD-FMF 105 / 1200B

|

105

|

28:1

|

2

|

1200

|

70

|

18.5

|

6000kg

|

Hot Searches