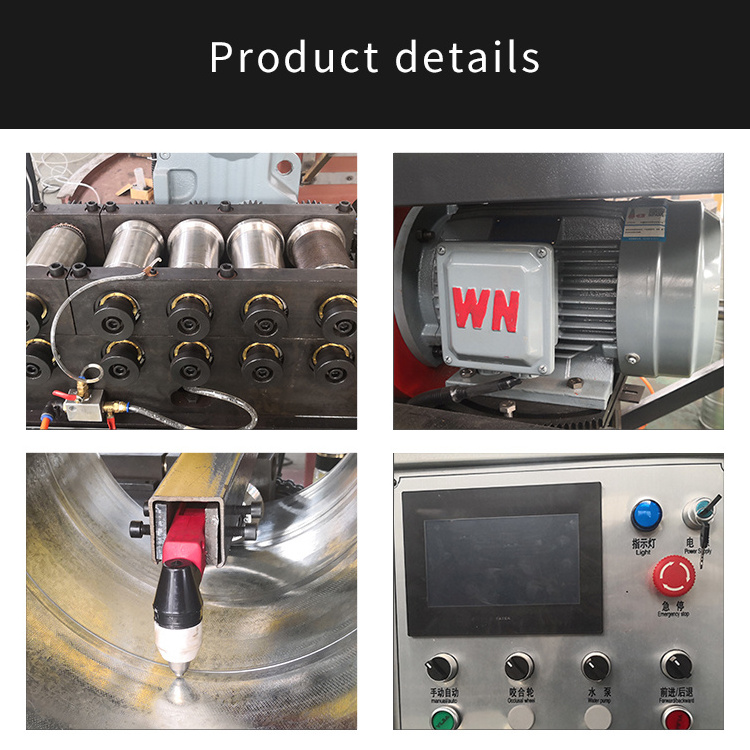

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

3250x1900x1830mm

-

Sheet Thickness (mm):

-

1.2mm

-

Production Capacity:

-

1-38m/min

-

Pipe Material:

-

Carbon Steel

-

Voltage:

-

Customized

-

Model:

-

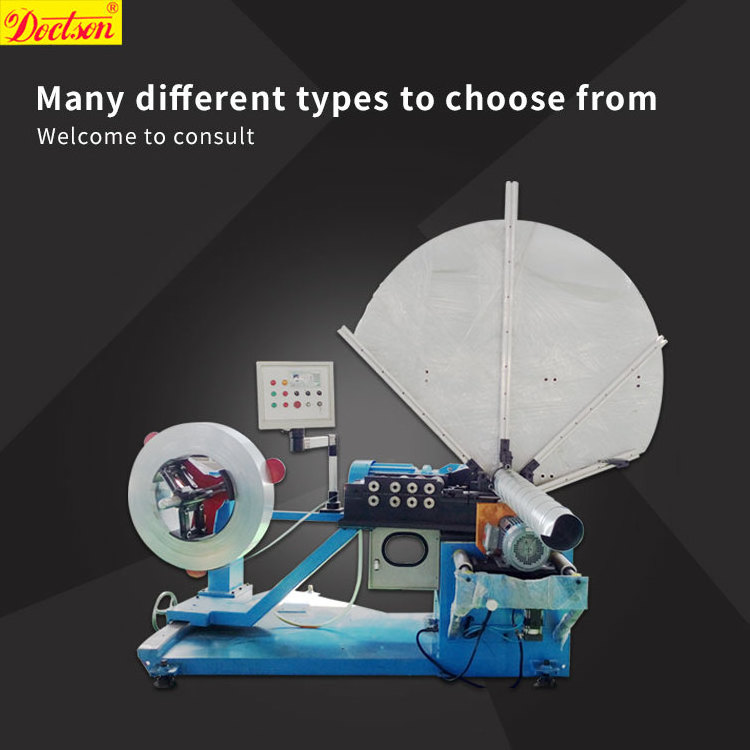

MYTF-1500 HVAC duct making machine / spiral duct making machine

-

Width:

-

Standard 137mm

-

Lock seam:

-

Outside tube,one the inside on request

-

Cutting system:

-

Saw blade cutting / Plasma cutter optional

Quick Details

-

Brand Name:

-

Doctson

-

Condition:

-

New

-

Weight:

-

2280 kg

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

3250x1900x1830mm

-

Sheet Thickness (mm):

-

1.2mm

-

Production Capacity:

-

1-38m/min

-

Pipe Material:

-

Carbon Steel

-

Voltage:

-

Customized

-

Model:

-

MYTF-1500 HVAC duct making machine / spiral duct making machine

-

Width:

-

Standard 137mm

-

Lock seam:

-

Outside tube,one the inside on request

-

Cutting system:

-

Saw blade cutting / Plasma cutter optional

Specification

|

Diameter range

|

Φ80-Φ1500mm

|

|

Tube Length

|

100-8000mm

|

|

Thickness of Strip

|

0.4-1.2mm

|

|

Width of Strip

|

137mm

|

|

Strip Speed

|

1-38/min

|

|

Dimension (L x W x H):

|

3250*1900*1830mm

|

|

Lock seam

|

Outside tube, on the inside on request

|

|

Weight

|

2280kg

|

|

Control System

|

PLC automatic control

|

|

Compressed air power

|

0.4-0.8kmp

|

|

Electrical

|

380V/3PH/50HZ(According to customer’s request)

|

|

Main Motor Power

|

5.5kw

|

|

The power of cutting motor

|

4kw

|

|

Suitable Material

|

Aluminum, Stainless steel, Galvanized steel

|

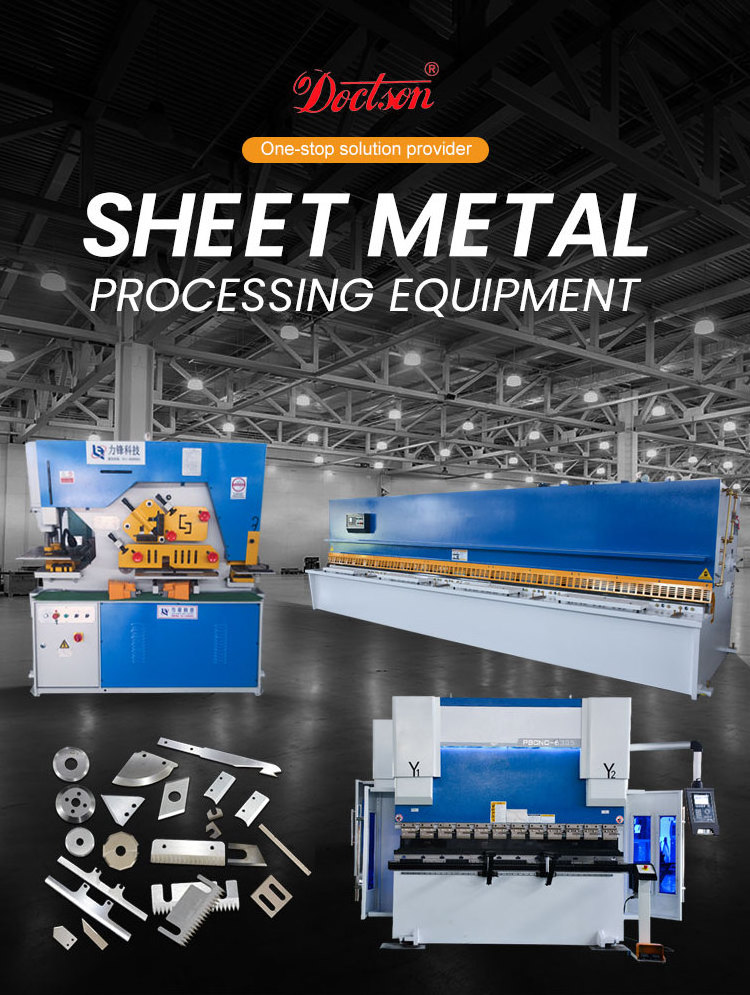

Main Feature:

Spiral duct making machine can be directly on the material spiral duct making machine can be directly on do flange bending machine, sheet of same board using flange is essential used do flange bending machine process of practical equipment, but also can be used as a general ruffled machine used as a general ruffled machine use.

Spiral tube coil is made of spiral seam of thin walled tube, metal belt round, no welding, no leakage, no Water Leakage, used for air and bulk transport, instead of the traditional tin pipe (i.e. manual seam pipe). A wind pipe, the straight pipe without manual mechanism on the main purposes are as follows:

1.air, including ventilation, such as air supply and exhaust, the range is very wide, such as factory workshop, the production site needs to be discharged due to outdoor air, harmful gas, and need to be transported to the indoor outdoor air. Then it is necessary to use large flow and low pressure air delivery pipe, spiral duct is the most suitable, use galvanized iron pipe in general, corrosive and wet places stainless steel tube.

2. to send cold air. The most common is the central air-conditioning pipe, this pipe need to add heat preservation material.

3. Hood Hotel, restaurant, hotel kitchen has a lot of fume, need to discharge, using circular duct is fume chimney. Here, the spiral duct is called the fume pipe.

4.dust removal. There are many factories in the production workshop a lot of dust, the need for specialized dust removal device, in which the air flow is larger, can be used in a spiral duct.

5.bulk material transport. In some factories, the production process, need to transport loose particles, in particular, the proportion of small, such as foam plastic particles, such as the use of a low cost, good effect.

●lock seam can be inner or outer lock for option.

●PLC control system with button operation

●Fast change steel duct mould system.

●Cutting system can be plasma and roller shear for different thickness

Product Picture

Hot Searches