- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1500*2100*3000mm

-

Power (kW):

-

40 kW

-

Weight (KG):

-

7000 KG

-

history:

-

more than 30 years history

-

quality:

-

best quality in china

-

Power(W):

-

75KW

-

Weight:

-

22T

-

Operation:

-

2-4 Workers

-

Electric part:

-

CHNT

-

Heating:

-

Electric Heating

-

Adapt tire:

-

CAR/TRUCK TIRE

-

Final product:

-

NEW TIRE

-

Capacity:

-

1000-1500 Tires/month

-

Certification:

-

CE/ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GY

-

Voltage:

-

220v/380v/as customers requirement

-

Dimension(L*W*H):

-

1500*2100*3000mm

-

Power (kW):

-

40 kW

-

Weight (KG):

-

7000 KG

-

history:

-

more than 30 years history

-

quality:

-

best quality in china

-

Power(W):

-

75KW

-

Weight:

-

22T

-

Operation:

-

2-4 Workers

-

Electric part:

-

CHNT

-

Heating:

-

Electric Heating

-

Adapt tire:

-

CAR/TRUCK TIRE

-

Final product:

-

NEW TIRE

-

Capacity:

-

1000-1500 Tires/month

-

Certification:

-

CE/ISO

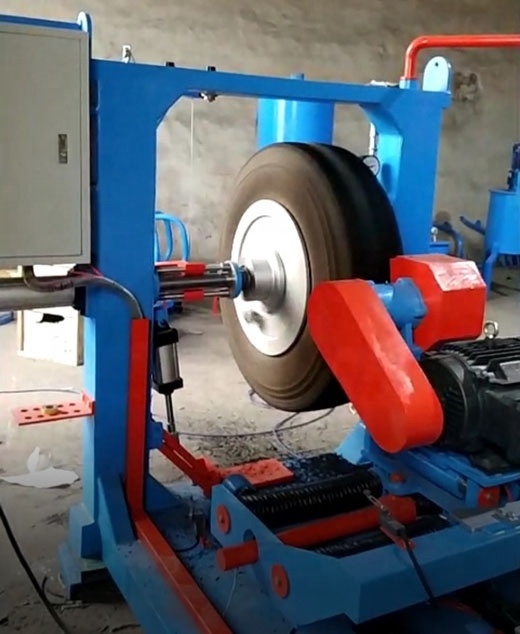

truck tire tread building machine / Waste tyre retreading machine

1. whole line

2.Function Description

a.Suitable for double-envelope curing, rim&tube curing and envelope-sealing ring curing

b.Display the curing parameters and the working state of kay components

c.Alarm when fault happens also has fault analysis

d.Adopt isolation transformer to keep PLC work smoothly

e.Heating tube heat alternately when start curing,maintain temperature balance

d.Optional Tire size:5"-15", 15"-22.5", 22.5"-25", 25"-33".

Can be designed according to your output.

3.The process as follow

tyre clean firstly dry tyre → inspecting tyre → buffing tyre → buffing outer wound of tyre → buffing inner wound of tyre → secondly inspecting tyre → repair inner wound → brushing adhesive on roof of tyre → secondly drying tyre → repair outer wound → affix middle rubber piece → tread building →assemble envelop → assemble inner tyre → assemble curing rim → inspecting inner tyre and curing rim → curing→ disassemble curing rim→ disassemble inner tyre → disassemble envelop → inspect end product → embellish tyre→ store tyre.

4, Equipment List:

the tyre retreading production line contains the following equipment:

* standard (necessery)

1. vulcanizing tank

2. inflatable tyre grinding machine

3. rubber powder collecting tank

4. inflatable tread pressing machine

5. rim disassembling machine

6. envolop disassembly machine

7. buffer strip extruder

8. rubber cement mixing tank

9. multifunctional tire repairing machine

10. circular gulding rail frame

11. hanging hook

* Optional Equipment

1. expansion tire for testing machine

2. tyre repair and cutting machine

3. tyre repair frame

5. Technical parameters

Specification 16 pcs Curing Chamber for Truck Tyre

Range of Tyre Size Within Size of 12.00-24 Truck and Passage Bus Tyre

Operating Worker No Min. 4Staff(6 staff better)

Workshop Area Min. 350m2

Curing Time 220Minutes/per shift(Timing at 112℃)

Max Daily Work Shift 4ps/day

Max Daily Output 64 pcs/day for within ruled max size tyre

Min Required Power 380V,50HZ.,80KW

Min Required Air Supply 0.8Mpa

Min Air Compressor 1pcs(Air Displacement:1.5m3/min;

Work Prssure:1.20Mpa;Auto Power:11KW

Min Required Air Storage 1pc(Storage Volume:1M3;

Work Prssure:1.25Mpa;Temperature:100℃)

5.1. Introduction for curing chamber

1. Vulcanizing boiler design and manufacture in strict accordance with the national standard of "" steel pressure vessel, and according to the country" pressure vessel safety design review project "the relevant requirement of inspection.

2. According to the heating mode can be divided into steam pressure, electrical heating and heat conduction oil heating three forms.

3. According to different division control circuit for PLC control and PLC control add touch screen display two kinds.

5.2. Equipment features

1. Use anti-oxidation electric heating tube, useful life extend one time.

2. Equipment with cycle water cooling system, ensure seal high run, avoid damage.

3. The operating system can be devided into semi-automatic control and automatic control.

4. Adopt high –capacity draught fan ensure the temperature and the wind speed evenly.

5. According to the customers requirement to machining and process.

5.3. Technical parameter

|

Classification/model |

RT-1500 |

RT-2000 |

RT-2200 |

RT-2500 |

RT-3000 |

|

1 |

2 |

3 |

4 |

5 |

|

|

Diameter (mm) |

1500 |

2000 |

2200 |

2500 |

3000 |

|

Effective length (mm) |

3000-20000 |

3000-20000 |

3000-20000 |

3000-30000 |

3000-30000 |

|

Material |

16MnR/Q235B |

||||

|

Design temperature |

180°C |

||||

|

Experiment pressure |

1.0Mpa |

||||

6.Picture

The combination of three-dimension CAD system and Internet guarantees the synchronization with international advanced technology. The combination of three-dimension CAD and CNC numeral process center realizes the transit from traditional manufacture to modern three-dimension manufacture. At the same time, our company keeps good contact with several universities and research institutes.

Our company takes "To live by quality, To develop by reputation, To innovate by science and technology, To keep improving all the time" as management idea, and insists on the principle of "Quality is the first, Reputation is first, Client is the first". We will provide you with the best service.