- Product Details

- {{item.text}}

Quick Details

-

Fiber Diameter:

-

3-5 um

-

Thermal Conductivity:

-

0.11w/m.k(1000C)

-

Density (kg/m³ ):

-

160

-

Place of Origin:

-

Henan, China

-

Width:

-

610,1220 mm

-

Length:

-

10,000-60,000 mm

-

Shrinkage (1800℉, 3h):

-

3.0(24hours)

-

Brand Name:

-

RongSheng, RongSheng

-

Model Number:

-

Ceramic Fiber Paper

-

Product Name:

-

Ceramic Fiber Paper

-

Certificate:

-

ISO9001 CE

-

Keyword:

-

Ceramic Fiber Paper

-

Feature:

-

Thermal Insulation

-

SiO2 %:

-

>40

-

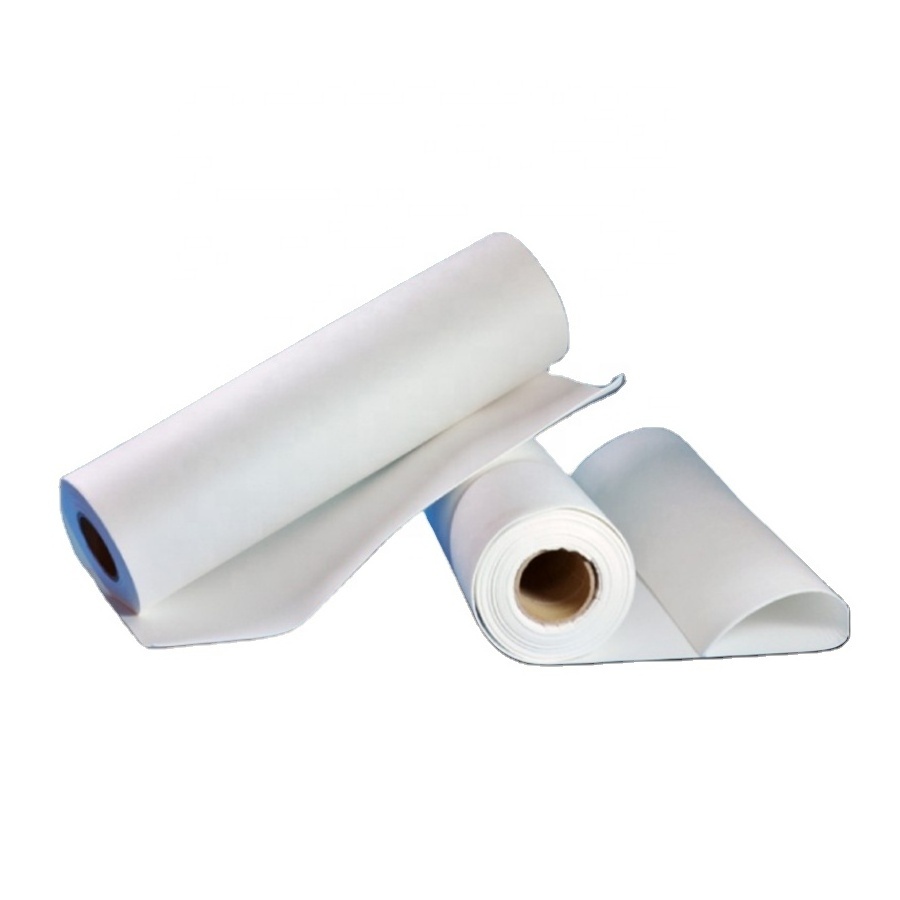

Color:

-

White

Quick Details

-

Chemical Composition:

-

Al2O3+SiO2, Al2O3,Sio2

-

Ultimate Strength (≥ MPa):

-

0.3

-

Working Temperature:

-

1000-1300, 1000-1350

-

Fiber Diameter:

-

3-5 um

-

Thermal Conductivity:

-

0.11w/m.k(1000C)

-

Density (kg/m³ ):

-

160

-

Place of Origin:

-

Henan, China

-

Width:

-

610,1220 mm

-

Length:

-

10,000-60,000 mm

-

Shrinkage (1800℉, 3h):

-

3.0(24hours)

-

Brand Name:

-

RongSheng, RongSheng

-

Model Number:

-

Ceramic Fiber Paper

-

Product Name:

-

Ceramic Fiber Paper

-

Certificate:

-

ISO9001 CE

-

Keyword:

-

Ceramic Fiber Paper

-

Feature:

-

Thermal Insulation

-

SiO2 %:

-

>40

-

Color:

-

White

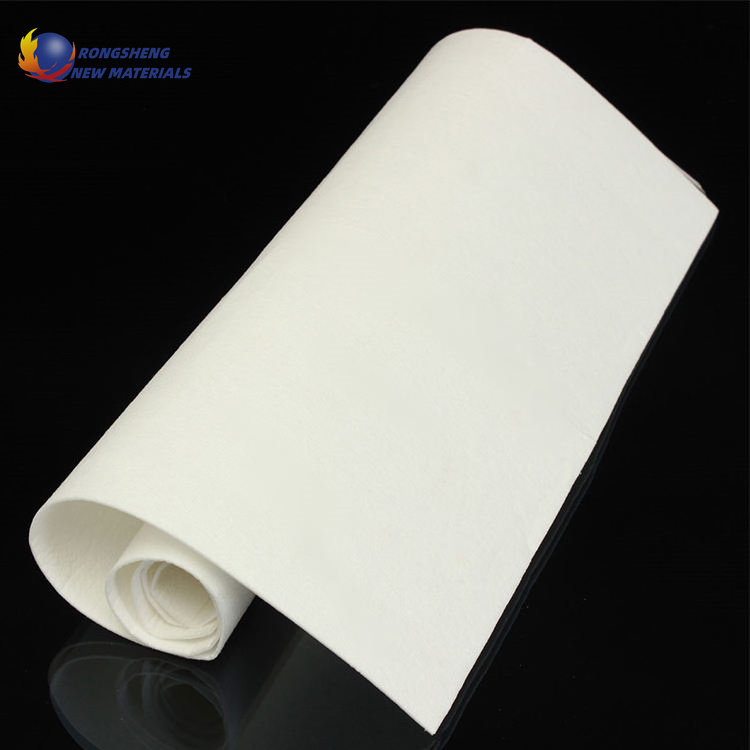

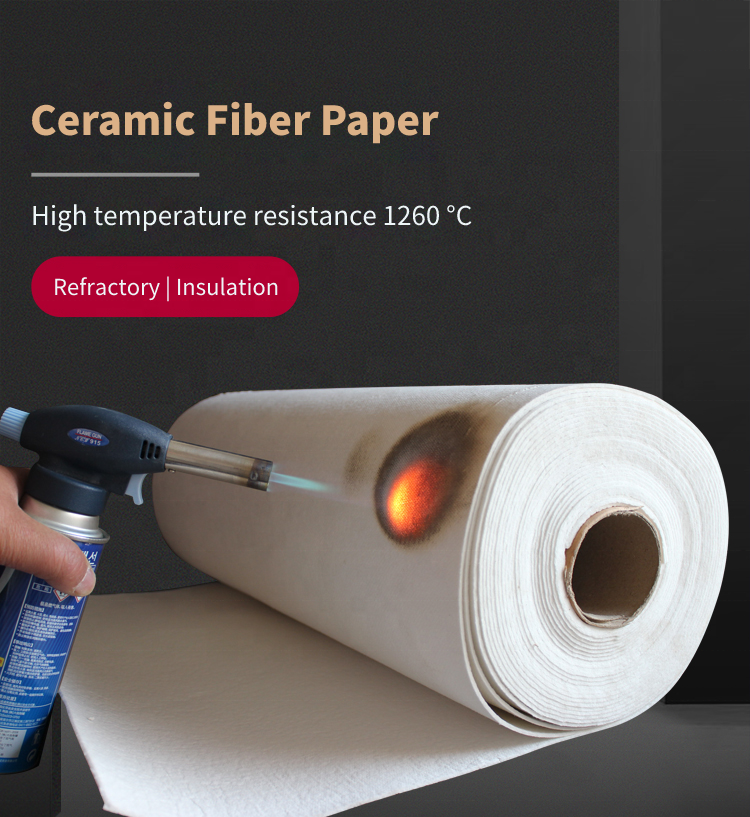

Ceramic Fiber Paper

Ceramic fiber paper is made of refractory fiber cotton as the main raw material, has a uniform structure and soft paper-like material produced by a conventional paper making process. In the production of refractory ceramic fiber paper, refractory cotton with different classification temperatures is used as the main raw materials, such as ordinary refractory cotton, high purity refractory cotton, high aluminum refractory cotton, zirconium containing refractory cotton as the main raw materials. There are have high quality ceramic fiber paper for sale in RongSheng factory and application for the sealing, gasketing, insulation, sound absorption and filtration at high temperatures furnaces.

|

Ceramic Fiber Paper

|

|

|

|

|

|

|

||||||

|

|

|

XWZ1000

|

XWZ1260

|

XWZ1430

|

XWZ1500

|

XWZ1600

|

||||||

|

Classification Temperature ℃

|

|

1000

|

1260

|

1430

|

1500

|

1600

|

||||||

|

Volume Density(kg/m3)

|

|

210

|

210

|

210

|

160

|

180

|

||||||

|

Rate of Linear %

℃×24h |

|

3.5(850)

|

3.0(1100)

|

3.2(1200)

|

3.6(1400)

|

3.4(1500)

|

||||||

|

Tensile Strength MPa

|

|

0.5

|

0.65

|

0.7

|

0.6

|

0.6

|

||||||

|

Organic Content %

|

|

10

|

8

|

6

|

7

|

7

|

||||||

|

Thermal Conductivity W/(m·K)

|

600℃

|

0.08

|

0.09

|

0.08

|

0.08

|

0.07

|

||||||

|

|

800℃

|

0.14

|

0.13

|

0.12

|

0.12

|

0.11

|

||||||

|

Al2O3 %

|

|

42

|

46

|

35

|

40

|

70

|

||||||

|

SiO2 %

|

|

54

|

50

|

44

|

58.1

|

28

|

||||||

|

ZrO2 %

|

|

-

|

-

|

15.5

|

-

|

-

|

||||||

|

Cr2O3 %

|

|

|

-

|

|

2.5

|

-

|

||||||

Excellent Raw Materials

1.

Ceramic fiber insulation paper has less residue, insulating ceramic fiber paper has good electrical insulation, and refractory ceramic fiber paper is a uniform, thin refractory fiber paper.

2.

Low thermal conductivity, excellent wind erosion resistance, and good electrical insulation. Refractory ceramic fiber paper has good flexibility and can be wound and punched

.

3.

Easy to cut and install, can meet requirements at will, precise control of size. The construction is convenient, no material is wasted, and the leftover materials can be used as caulking materials.

Continuous production

4.

The fibers are evenly distributed, the performance is stable, and the service life is long. The adsorption time is precisely controlled, vacuum dehydration is performed, and the packaging is tight.

1.Insulation material for home application.

2.Crystallite glass and hot melt (curved)glass stripping.

3.Door and sealing expansion joints of industrial furnaces.

4.Exhaust pipe insulation, isolation anti-sintering materials.

5.Sound adsorption and thermal insulation materials of mobile mufflers.

6.Electric insulation and thermal insulation materials of industrial furnaces.

7.Thermal insulation material of industrial furnaces,steel ladles, and foundry ladles.

2.Crystallite glass and hot melt (curved)glass stripping.

3.Door and sealing expansion joints of industrial furnaces.

4.Exhaust pipe insulation, isolation anti-sintering materials.

5.Sound adsorption and thermal insulation materials of mobile mufflers.

6.Electric insulation and thermal insulation materials of industrial furnaces.

7.Thermal insulation material of industrial furnaces,steel ladles, and foundry ladles.

Customer Photos

Exhibition

Hot Searches