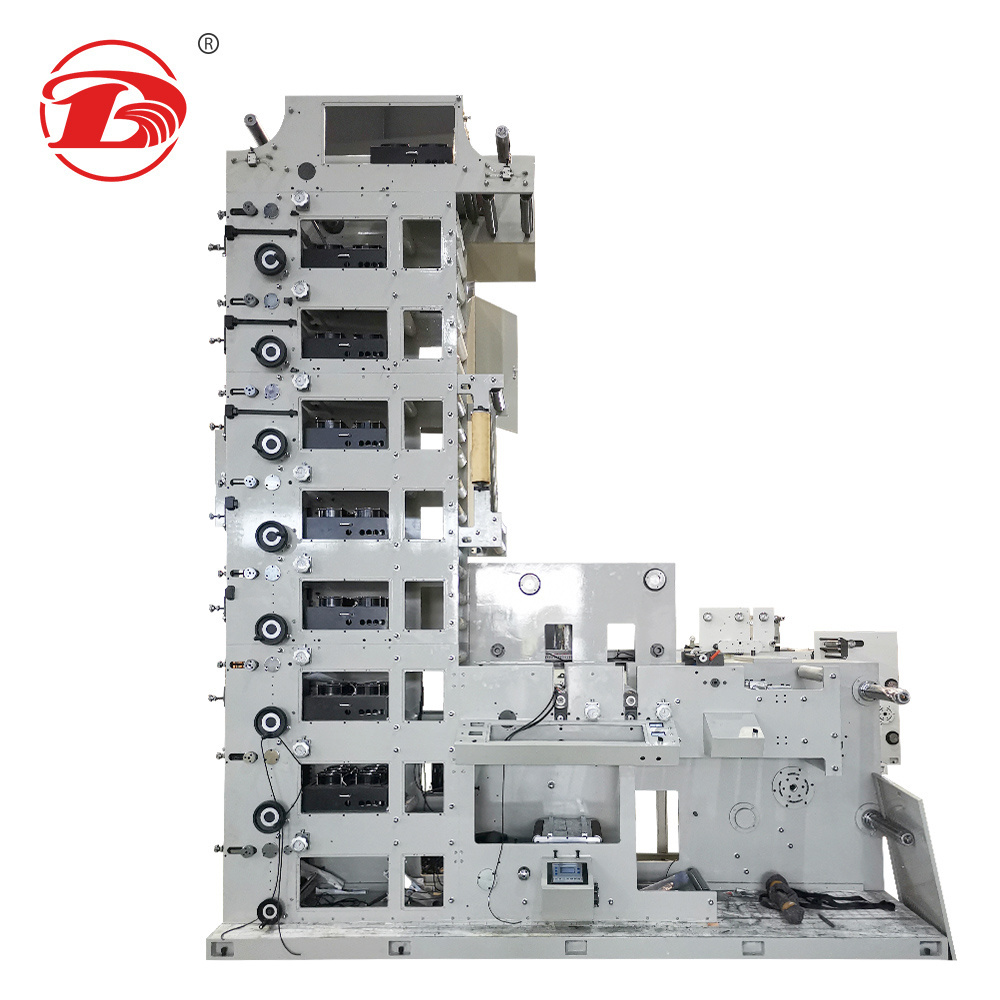

- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

4200*2160*3150mm

-

Weight:

-

5000 KG

-

Printing material:

-

Paper,Film,Adhesive Paper

-

Application:

-

Flexible Label Printing

-

Printing color:

-

1-10 Colors

-

Printing type:

-

Flexo Press

-

Suitable material:

-

Roller Paper

-

Printing length:

-

191-1200mm

-

After-sales service:

-

Service Machinery Overseas

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DaBa

-

Voltage:

-

380V

-

Dimensions(L*W*H):

-

4200*2160*3150mm

-

Weight:

-

5000 KG

-

Printing material:

-

Paper,Film,Adhesive Paper

-

Application:

-

Flexible Label Printing

-

Printing color:

-

1-10 Colors

-

Printing type:

-

Flexo Press

-

Suitable material:

-

Roller Paper

-

Printing length:

-

191-1200mm

-

After-sales service:

-

Service Machinery Overseas

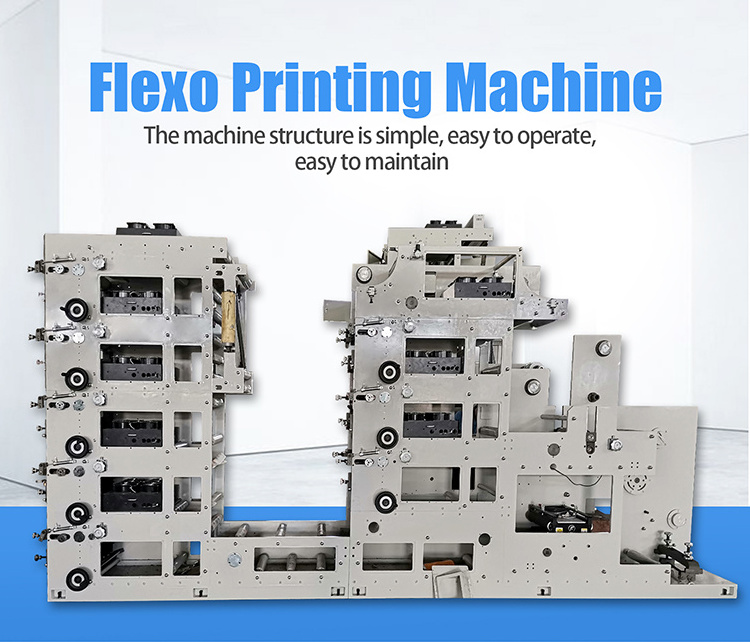

Product Description

Main Features

* 1. Main motor adopts imported frequency step-less speed regulator.

* 2. Unwinding,traction and rewinding are controlled by magnetic powder arrester,clutch and tension inspector. Tension controller is automatic type.

* 3. Machine adopts ceramic anilox roller, which is characterized by wearable,rust-resistant and long using life, etc.It can

improve the printing efficiency.

* 4. Printing unit adopt plate register function,each veins roller can print independently,without effecting others when leave it alone.

* 5. Each printing unit collocated with IR dryer, the UV dryer is optional.

* 6. The ink roller can break away automatically when machine stops,and it still run in a low speed avoid the ink dry or

asymmetric.

* 7. Unwinding and rewinding shaft adopt air shaft,it's convenient to change load and unload the material.

* 8. From material-feeding, printing, drying, glazing, laminating, molding, die-cutting, rewinding to waste-collecting can be done in the same machine, the machine is known for machine characteristics such as wide printing range, environmental ink, fast printing speed, convenient operation, high economic benefit and so on. It's the best choice for note, paperboard and label printing factories.

* 2. Unwinding,traction and rewinding are controlled by magnetic powder arrester,clutch and tension inspector. Tension controller is automatic type.

* 3. Machine adopts ceramic anilox roller, which is characterized by wearable,rust-resistant and long using life, etc.It can

improve the printing efficiency.

* 4. Printing unit adopt plate register function,each veins roller can print independently,without effecting others when leave it alone.

* 5. Each printing unit collocated with IR dryer, the UV dryer is optional.

* 6. The ink roller can break away automatically when machine stops,and it still run in a low speed avoid the ink dry or

asymmetric.

* 7. Unwinding and rewinding shaft adopt air shaft,it's convenient to change load and unload the material.

* 8. From material-feeding, printing, drying, glazing, laminating, molding, die-cutting, rewinding to waste-collecting can be done in the same machine, the machine is known for machine characteristics such as wide printing range, environmental ink, fast printing speed, convenient operation, high economic benefit and so on. It's the best choice for note, paperboard and label printing factories.

|

Machine Parameter

|

|

|

|

|

|

|

|

|

||||||||

|

Model

|

DBRY320

-1C |

DBRY320

-2C |

DBRY320

-3C |

DBRY320

-4C |

DBRY320

-5C |

DBRY320

-6C |

DBRY320

-7C |

DBRY320

-8C |

||||||||

|

Printing speed

|

70m/min

|

|

|

|

|

60-80m/min

|

|

|

||||||||

|

Printing color quantity

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

||||||||

|

Max. unwinding width

|

350mm

|

|

|

|

|

|

|

|

||||||||

|

Max. Printing width

|

320mm

|

|

|

|

|

|

|

|

||||||||

|

Min. Printing width

|

60mm

|

|

|

|

|

|

|

|

||||||||

|

Max. unwinding diameter

|

600mm

|

|

|

|

|

|

|

|

||||||||

|

Max. rewinding diameter

|

600mm

|

|

|

|

|

|

|

|

||||||||

|

Precision of chromatography

|

±0.10mm

|

|

|

|

|

|

|

|

||||||||

|

Machine weight

|

1800KG

|

2100KG

|

2400KG

|

2700KG

|

3000KG

|

3300KG

|

3600KG

|

3900KG

|

||||||||

Samples show

Applicable Material:

* Self-adhesive paper,Self-adhesive thermal paper,thermal paper ATM etc.

* Self-adhesive film:Self-adhesive PE film,Self-adhesive PET film,Self-adhesive PVC film,etc.

* plastic film:Cpp film,PET film,PVC film,PE film,etc.

* Laminating Film.

* Paper material:kraft paper,paper cup paper,etc.

* Self-adhesive film:Self-adhesive PE film,Self-adhesive PET film,Self-adhesive PVC film,etc.

* plastic film:Cpp film,PET film,PVC film,PE film,etc.

* Laminating Film.

* Paper material:kraft paper,paper cup paper,etc.

Application Industry:

* Food product label, Anti-counterfeit label, Daily chemical products label, Medicines label, Chemical label, Paper cup paper,Blank label,etc.

Details Images

Unwinding Unit

1.1 Unwinding

Auto tension control–No roll-followers or external sensors to be adjusted or maintained. Support a stable unwinding tension

1.2Corona treatment(Optional)

Web guide system

EPC system to ensure the printing material the lateral position before feeding to the printing station. Ultrasonic Web Guide System,transparent products can be easily detected. The precision is ±0.1mm.

Flexo Printing Unit

Printing driven by 3 kw motor. It could by controlled at the control panel independently.

Printing station consist with :Measuring roller(Rub roller) ,Ceramic anilox roller, printing roller, scrapper 360°degree printing adjustment.

Splice Table

Turn Bar Horizontal Adjuster

quick change air shaft. Feeding by motor.

Turn Bar Vertical Adjuster

quick change air shaft. Feeding by motor.

Waste Matrix Remove Unit

Laminating Unit

A driven capstan roller with adjustable tension control ensures reliable matrix stripping, enabling high speed running even if the matrix rewind becomes unstable.

Die Cutting Unit

With 8 pcs rotary knives Automatic magnetic powder tension control Special blades can be customized according to the product

Rwinding Unit

Auto tension control ensure the rewinding tension is tight and rewinding edge is clean.

Cold Stamping Unit

Need use UV glue with UV oven. Cold stamping can be placed at any position.

Cross cutting unit

Slitting System

Camera

Die Hoist

UV Dryer

Delarm&Relarm Unit

Electric Register System

In Factory Photo

Our Service

1.Purchase Service

DABA COMPANY have a specialize and efficiency working team.If you are new onthe printing and packing area Some samples of your

products could be shew to uswill be appreicate we will give you specialized suggestion of whole work

2.Shipping Service

DABA COMPANY have a spcialized and independent department which just for

shipping the buyer's goods.The workers are knowing T/T,L/C Items well.All Exporteddocuments could be made perfectly

DABA COMPNAY cooperate with the most famous shipping company in China also.

They could provide the best and economic shipping ways to the buyer's port.

3.Installation Services

Installation Services are available with all DABA Company machines.DABA Comapnywill dispatch technician to The Buyer's factory to

installation and preoperation ofmachines But the buyer need to surpply the round trip tickets food hotel cost.

4.Clients Training Services

DABA Company advise The buyer could send own technican come to DABA factoryto learn how to operate machines.DABA Company

technician will teach and train thelerners hand by hand till he can operate machine by himself.

Obviouslly,Traning within Installation period is acceptable.

5.After Sales Service

DABA Company machines guarantee time is one year.

Many easy broken spare parts will be prepared in the tool box together with

machines.Any parts broken Just a pictures or a videos.The new free parts will reachwithin 3-7 Express working days.

DABA COMPANY have a specialize and efficiency working team.If you are new onthe printing and packing area Some samples of your

products could be shew to uswill be appreicate we will give you specialized suggestion of whole work

2.Shipping Service

DABA COMPANY have a spcialized and independent department which just for

shipping the buyer's goods.The workers are knowing T/T,L/C Items well.All Exporteddocuments could be made perfectly

DABA COMPNAY cooperate with the most famous shipping company in China also.

They could provide the best and economic shipping ways to the buyer's port.

3.Installation Services

Installation Services are available with all DABA Company machines.DABA Comapnywill dispatch technician to The Buyer's factory to

installation and preoperation ofmachines But the buyer need to surpply the round trip tickets food hotel cost.

4.Clients Training Services

DABA Company advise The buyer could send own technican come to DABA factoryto learn how to operate machines.DABA Company

technician will teach and train thelerners hand by hand till he can operate machine by himself.

Obviouslly,Traning within Installation period is acceptable.

5.After Sales Service

DABA Company machines guarantee time is one year.

Many easy broken spare parts will be prepared in the tool box together with

machines.Any parts broken Just a pictures or a videos.The new free parts will reachwithin 3-7 Express working days.

Packing & Delivery

Hot Searches