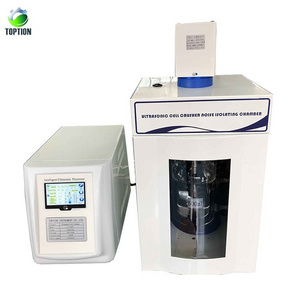

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HAainertec

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

35*40*20

-

Power (kW):

-

0.3 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Product name:

-

Homogenizing Emusifying Machine

-

Material:

-

Stainless Steel 304 / SUS316L

-

Function:

-

Mixer Blender

-

Usage:

-

Liquid Treatment

-

Certification:

-

ISO

Quick Details

-

Barrel Volume (L):

-

2 L

-

Max. Loading Volume (L):

-

1 L

-

Weight (KG):

-

5 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HAainertec

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

35*40*20

-

Power (kW):

-

0.3 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Product name:

-

Homogenizing Emusifying Machine

-

Material:

-

Stainless Steel 304 / SUS316L

-

Function:

-

Mixer Blender

-

Usage:

-

Liquid Treatment

-

Certification:

-

ISO

Products Description

The miniature size of power iltrasonic transducer also could use in insturments and apparatus, for example, precise cleaning of sampling needles, test-tubes, small glasswares, solution degassing, mixing and catalysis, drug guidance, cell-wall disruption, crushing, extraction, homogenization and separation of biological cell drugs, online anti-scaling and catalysis of liquid pipelines, powder screening and suspension of vibrating materials, etc. The industry requires small enough size, low input power and drive voltage. Based on the market demand, our company has developed the transducers for most of the above- mentioned.

When the high frequency vibration of power ultrasonic acts into water, it will produce different power densities of acoustic cavitation. The value of power density generated by traditional industrial ultrasonic cleaning technology is less than 0.7W/cm

². The application of high efficiency ultrasonic cleaning, plant extraction, chemical catalysis, cell disruption, biological treatment, sludge dewatering, oil-water separation, sludge treatment, oil water separation from cuede oil, tailings extraction need the high power density ultrasonic vibration, which the energy-gathering ultraonic technology is used in.

The vibration energy of energy-gathering ultrasonic transducer is locally concentrated, the models are as follws:

·Technology of multimodal plate ultrasonic transducer:

Ultrasonic vibration in multi direction with the power density of 2.0W/cm

²

.

·Technology of multimodal mutil-knot ultrasonic transdcer:

Ultrasonic vibration in axial and external dadial direction with the power density of 3W/cm

²

.

·Technology of multimodal hollow ultrasonic transdcuer:

Ultrasonic vibration in axial and internal and external radial direction with power density of 5W/cm

²

.

·Ultrasonic processing technology of axial fouusing pipeline:

Realizing the energy focusing of cross section inside the pipeline with the power density of 8W/cm

²

.

·Ultrasonic processing technology of axial working face:

Realizing the energy focusing in local small area with the max power density of 200W/cm

²

.

|

Model

|

Frequency

|

Capacitance ( nf )

|

Impedance

|

Power ( W )

|

Resistance

|

|

HSD-4020-SP

|

40±0.5

|

3000±10%

|

≤40Ω

|

20

|

100MΩ

|

|

HSD-2050-SP

|

20±0.5

|

2700±10%

|

≤30Ω

|

50

|

100MΩ

|

|

HSD-20100-SP

|

20±0.5

|

3650±10%

|

≤25Ω

|

100

|

100MΩ

|

|

HSD-30300-SP

|

30±0.5

|

7500±10%

|

≤20Ω

|

300

|

100MΩ

|

|

HSD-35200-SP

|

35±0.5

|

4500±10%

|

≤25Ω

|

200

|

100MΩ

|

|

HSD-40200-SP

|

40±0.5

|

4000±10%

|

≤25Ω

|

200

|

100MΩ

|

|

HSD-50200-SP

|

50±0.5

|

4500±10%

|

≤25Ω

|

200

|

100MΩ

|

|

HSD-20350-SP

|

20±0.5

|

9500±10%

|

≤25Ω

|

350

|

100MΩ

|

|

HSD-20500-SP

|

20±0.5

|

13800±10%

|

≤18Ω

|

500

|

100MΩ

|

|

HSD-20600-SP

|

20±0.5

|

12000±10%

|

≤22Ω

|

600

|

100MΩ

|

|

HSD-20800-SP

|

20±0.5

|

18000±10%

|

≤18Ω

|

800

|

100MΩ

|

|

HSD-301000-SP

|

30±0.5

|

9600±10%

|

≤15Ω

|

1000

|

100MΩ

|

|

HSD-201000-SP

|

20±0.4

|

9000±10%

|

≤15Ω

|

1000

|

100MΩ

|

Noter:

With high power sweep frequency circuit to rea;oze working face vibration.

We accept design and custom production.

This is siutble for small capacity and static or low velocity water processing in breakers or test tubes.

Corollary Equipment

Hot Searches