- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel, Villa, Apartment, Office Building, Hospital

-

Weight:

-

10kg

-

Chemical Composition:

-

steel

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

xingtong

-

Model Number:

-

xt

-

Material:

-

Steel

-

Process 1:

-

Material stock,Pressure weldind,cuting ,welding ends of bar

-

Process 2:

-

hot dip galvanizing, QC,packaging shipping

-

Offer Free Sample:

-

yes

-

Grating Size:

-

3'x20', 3'x24', 3'x30', 1000x1000 or can be customized

-

Company Type:

-

professional manufacture

-

Surface treatment:

-

Hot Galvanized

-

Shape:

-

serrated or pain

-

Product name:

-

galvanized steel grating

Quick Details

-

Warranty:

-

Lifetime

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design

-

Application:

-

Hotel, Villa, Apartment, Office Building, Hospital

-

Weight:

-

10kg

-

Chemical Composition:

-

steel

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

xingtong

-

Model Number:

-

xt

-

Material:

-

Steel

-

Process 1:

-

Material stock,Pressure weldind,cuting ,welding ends of bar

-

Process 2:

-

hot dip galvanizing, QC,packaging shipping

-

Offer Free Sample:

-

yes

-

Grating Size:

-

3'x20', 3'x24', 3'x30', 1000x1000 or can be customized

-

Company Type:

-

professional manufacture

-

Surface treatment:

-

Hot Galvanized

-

Shape:

-

serrated or pain

-

Product name:

-

galvanized steel grating

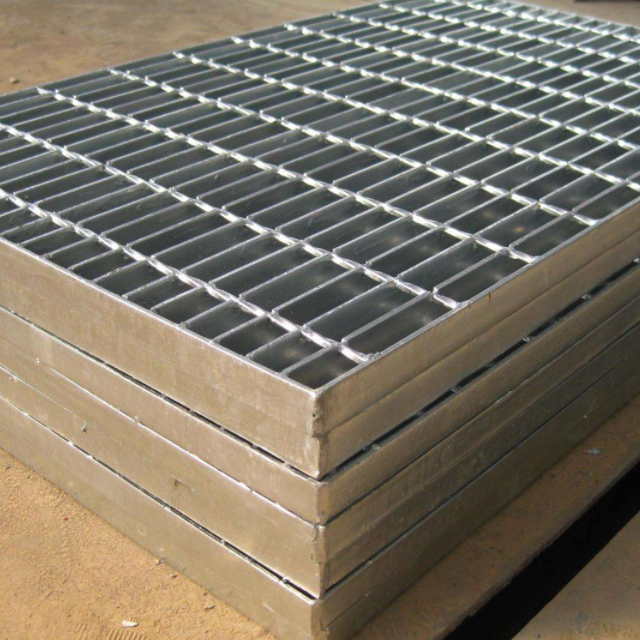

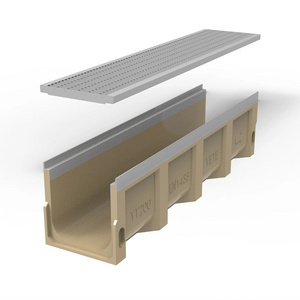

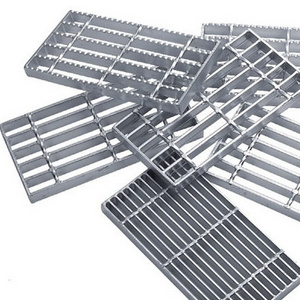

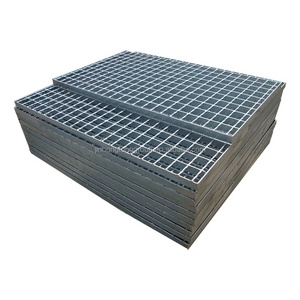

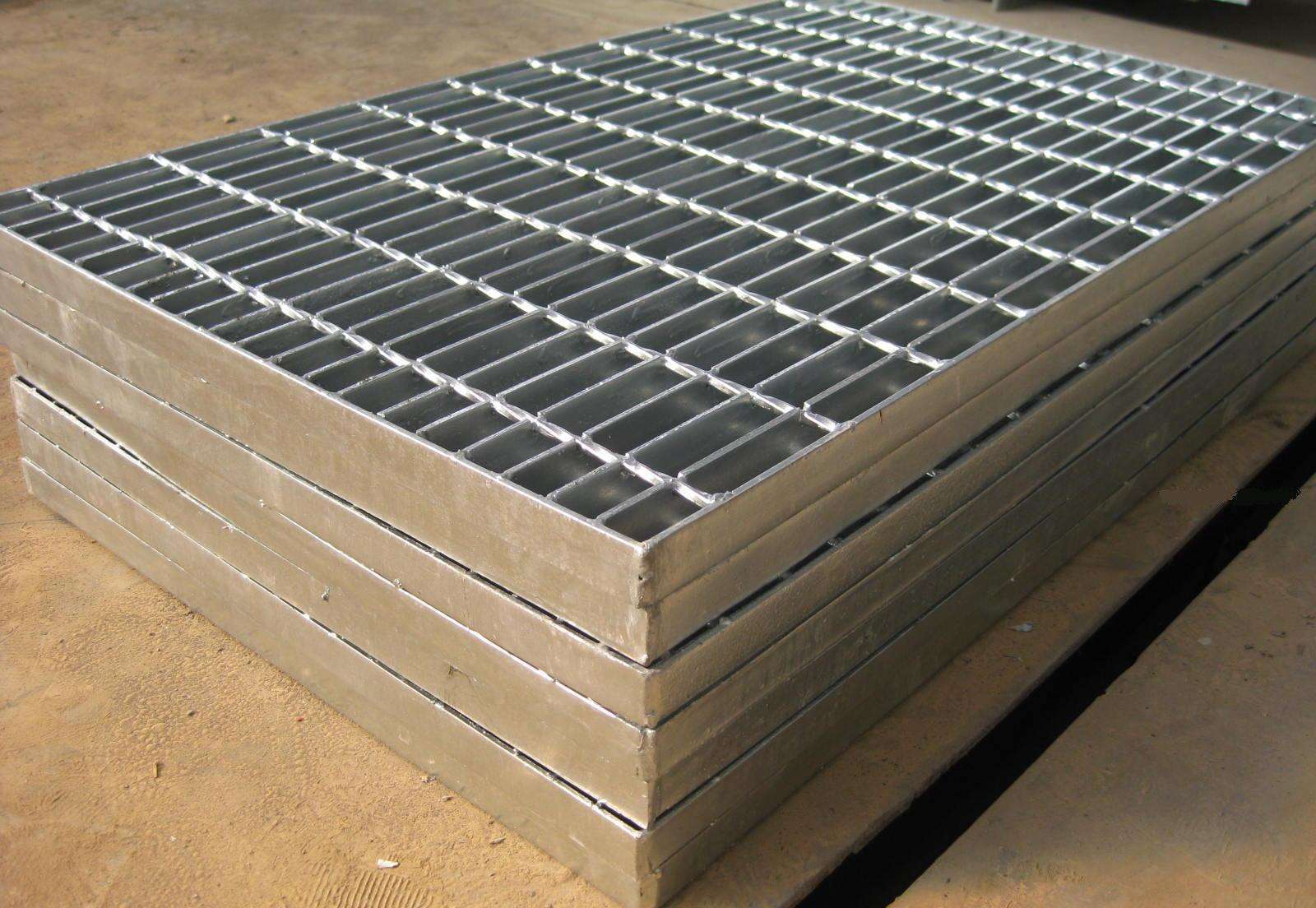

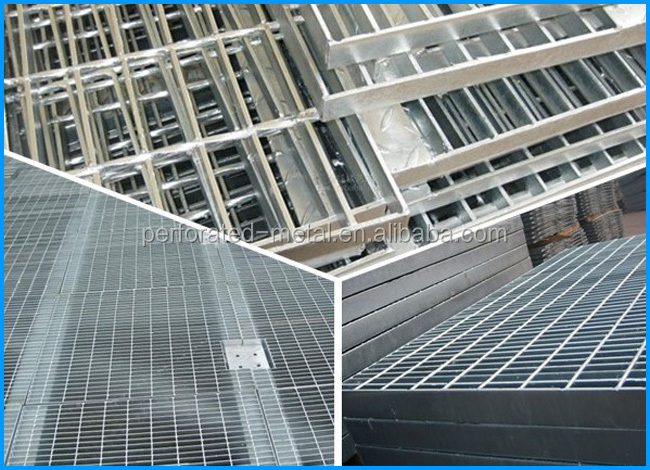

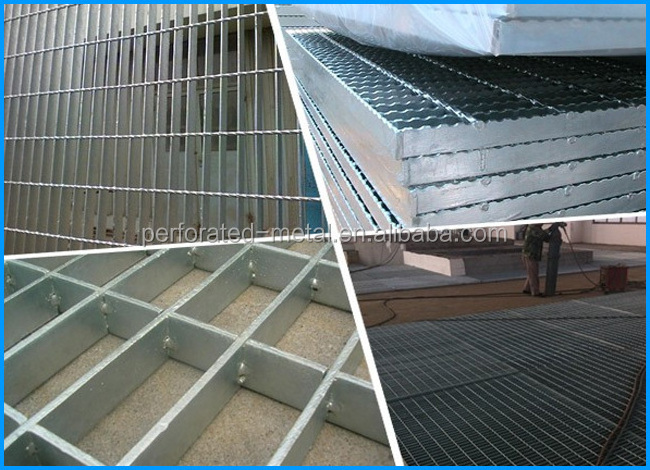

High quality hot dip galvanized steel grating, trench grating,steel bar grating

1.Introduction of hot dip galvanized steel grating

1>material: carbon steel or stainless steel

2>cross bar pitches: maybe 24-200mm,of which 50mm,76mm and 100mm are recommended.

3>Steel grating is made by the world first-class equipment,which can arrange the bearing bar and cross bar in longitude and latitude order to certain distance.cross bar is pressed into the bearing bar by high tension resistance weldingring which is controlled by computer.so we can produce high quality gratings with firm welding,smooth surface and high strength.

4>Surface process of steel grating : Types:hot-dipped galvanized,electro-galvanized ,spraying brushing. 95% people choose hot-galvanized because its anti-acid and alkali corrosion capacity range is from PH6 to PH12.5,a stable protective film will be formed on the zinc surface.it has good anti-corrosive property.

5>Attractive appearance: Simple outline.silver colour and modern.

6>Optimum water draining: Water leakage area reaches 83.3%,which is more than two times larger than that of cast iron.

7>Hot-dip galvanizing: Good antirust performance,maintenance free and replacement free.

8>Design of preventing theft: The cover is connected with the frame by gemel,which ensures protection against theft,safety and convenient opening.

|

Steel grating |

|

|

Place of Origin |

Hebei China (Mainland) |

|

Brand Name |

FD |

|

Model Number |

FD PT140609 |

|

Bearing bar |

30mm(height)x3mm(thickness) |

|

Bearing bar pitch |

30 |

|

Cross bar |

6x6 |

|

Cross bar pitch |

50mm,100mm |

|

Surface treatment |

Hot dip galvanized |

|

Flat bar type |

Plain |

|

Material standard |

Low carbon steel |

|

Galvanizing standard |

US: ASTM (A123) |

|

Steel grating standards |

USA: ANSI/NAAMM (MBG 531-88) |

|

Certification |

CE,SGS,ISO90001. |

|

Usage & Performance |

Industrial platform, flooring and walkway, traffic, steel structure |

|

Main market |

USA, Australia, Japan, etc. |

|

Packing |

1.Pallet in containers.

|

|

MOQ |

2/Tons |

|

Supply Ability |

500 Tons/month |

|

Payment Terms |

T/T,L/C |

|

Delivery Time |

within 15 days after your deposit or L/C at sight |

|

P ort of delivery |

FOB Tianjin |

|

Sample time |

7 days |

2.Surface Treatment of hot dip galvanized steel grating

- hot dipped galvanized

- Untreated

- Painting

- 95% people choose hot dipped galvanized because its anti-acid and alkali corrosion capacity range is from PH6 to PH12.5,a stable protective film will be formed on the zinc surface.it has good anti-corrosive property.

3.Process of hot dip galvanized steel grating

- We have our own factory and facility.

- Excellent hot-dip galvanizing process to achieve great anti-acid and alkali corrosion.

- We can manufacturer any kinds of specification as your demand.

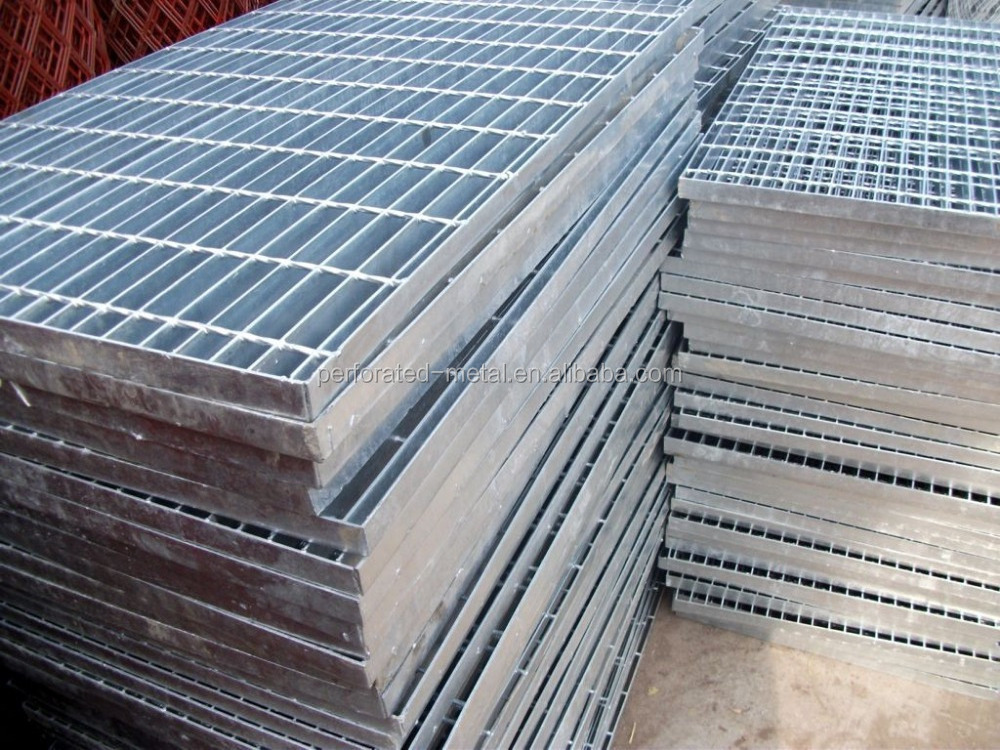

4.Packing and loading of hot dip galvanized steel grating

Normally packed in pilling up ways with two pieces of square wood on both upperand bottom sides.

there are four or six pieces of M10 long bolt penetrading the gratings and screwing together.

it is suitable for loading and unloading by fork-lift and crane.

5.Installation of hot dip galvanized steel grating

1>The shape of bearing bar: Plain type (may be omitted in the symbol of steel grating), Serrated type and I-Shape type.

2>Bearing bar pitches:

12.5, 15, 20, 30, 30.16, 32.5, 34.3, 40, 60mm, of which 30mm & 40mmare recommended.

3>Cross bar pitches:

38, 50, 60,100mm, of which 50mm & 100mm are recommended.