a) all rotating disk with stainless steel SUS304 welded together.

b) using this company original tilting bottles, bottle clamp stuck bottleneck, avoid the traditional bottle on rubber clip to block the bottle threaded parts may be caused by the pollution. Bottle holder is made of stainless steel SUS304 manufacturing, health, and durable.

c) by high spray nozzle, blunt bottle of water jet angles, flush to the bottle of any part of the inner wall, rinse with water thoroughly and save flush bottle.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

5ML

-

Voltage:

-

110V~480V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AK-MACHINE

-

Dimension(L*W*H):

-

2300*1800*2350MM

-

Weight:

-

3500 KG

-

Bottle type:

-

PET Plastic Bottle

-

Control:

-

PLC+ Touch Screen

-

Machine material:

-

Stainless Steel SUS 304/316L

-

Processing Types:

-

Automatic Bottle Filling Sealing Machine

-

Product name:

-

Automatic Bottle Washing Filling Capping Machine

-

Keywords:

-

bottle filling machine

-

Function:

-

Bottle Washing Filling Capping

-

Usage:

-

Beverage Filling Packaging

-

Filling material:

-

liquid water

-

Name:

-

beer making machine

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal, Glass, Other

-

Filling Material:

-

Beer, Milk, Water, Juice

-

Filling Accuracy:

-

5ML

-

Voltage:

-

110V~480V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AK-MACHINE

-

Dimension(L*W*H):

-

2300*1800*2350MM

-

Weight:

-

3500 KG

-

Bottle type:

-

PET Plastic Bottle

-

Control:

-

PLC+ Touch Screen

-

Machine material:

-

Stainless Steel SUS 304/316L

-

Processing Types:

-

Automatic Bottle Filling Sealing Machine

-

Product name:

-

Automatic Bottle Washing Filling Capping Machine

-

Keywords:

-

bottle filling machine

-

Function:

-

Bottle Washing Filling Capping

-

Usage:

-

Beverage Filling Packaging

-

Filling material:

-

liquid water

-

Name:

-

beer making machine

Product Description

High Quality can filling machine for carbonated beverage / carbonated filling machine / semi-automatic carbonated water machine

|

Model

|

CGF24-24-8

|

|

Station number

|

Washing24,Filling24,Capping 8

|

|

Capacity

|

Max 6000BPH

|

|

Way of filling

|

Isobaric filling

|

|

Air

|

0.8M3/min

|

|

Dimensions(mm)

|

2850×2150×2650

|

|

Weight (kg)

|

4000

|

DGF series carbonated Water Filling Machine apply to the production of carbonated drinks,carbonated beverage,carbonated water and low alcoholic drinks, etc.

Carbonated Water Filling Machine/ Filling Machine The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted. There the output and benefit of the machine is higher than the machinery of the same specifications.

The advanced OMRON programmed controller (PLC) is adopted to control the machine to run automatically while a transducer is used in the bottle -entering chains to adjust speeds and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably

-

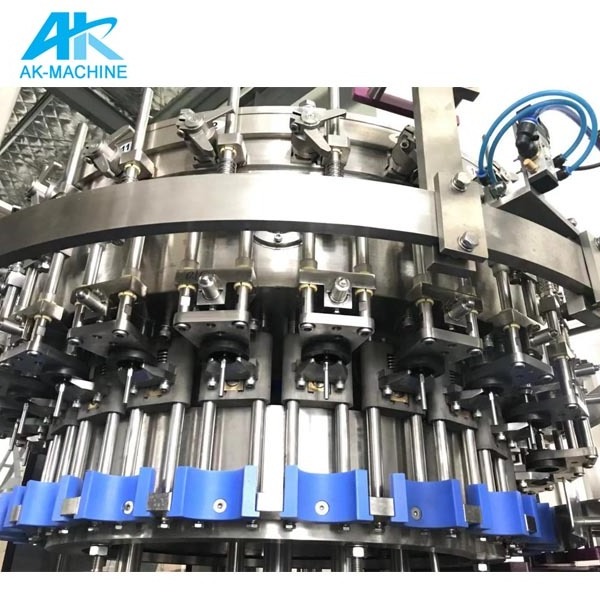

washing part

-

beer making machine

transition thumbwheel

beer pet bottle vending machine

card bottle stainless steel wheel

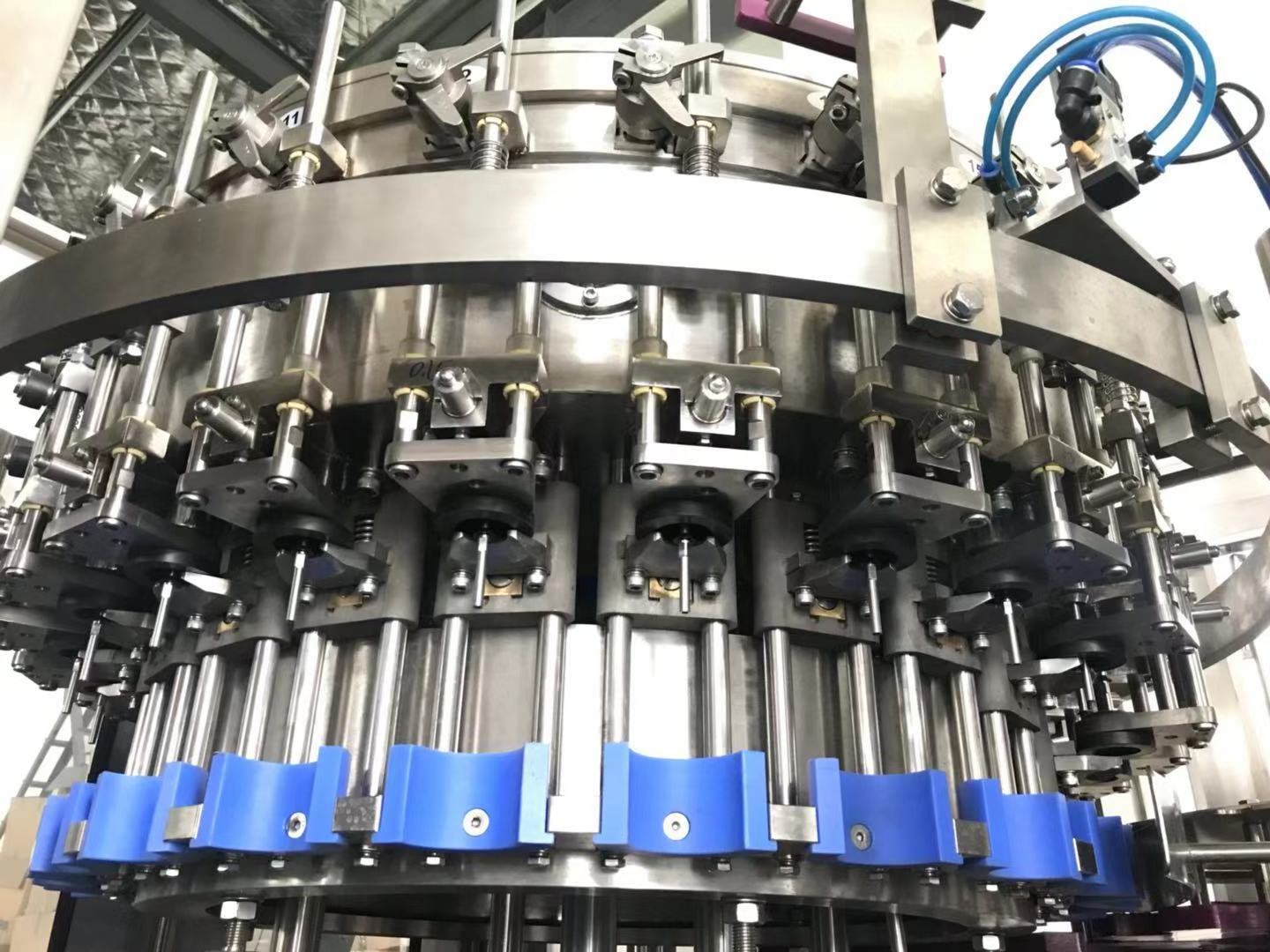

filling part

aluminium cans filling machine

a) rotate all adopt the stainless steel SUS304 manufacturing.

b) filling method for gravity filling.

c) filling valve manufactured SUS304.

d) high precision, high speed liquid filling valve, liquid level

e) with the hydraulic cylinder, hydraulic cylinder is controlled by a float liquid level.

f) using the latest double guide pillar type bottle of lifting mechanism, avoid the bottle of elevating the old products must be through the mesa caused by leakage on the edge.

cappping part

a) magnetic constant torque screw LIDS, screw cap effect is stable and reliable, block defect rate of 0.2% or less.

b) fall guy guide sets out to prevent the cover through and cover on the body, at the same time equipped with a set of photoelectric switch, automatic stop when lighted cover rail without cover machine, can effectively avoid the occurrence of open bottle.

c) high efficiency centrifugal principle, cover cover wear little.

Details Images

Related Products

Packing&Shipping

After Sales Service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 20-30 days,if complete production line it is 45-60 days.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance

Before shippment.

Partners

Hot Searches