- Product Details

- {{item.text}}

Quick Details

-

Rated Capacity:

-

2.5KVA

-

Rated Duty Cycle:

-

30%

-

Max. Welding Thickness:

-

0.3mm(Above 0.3mm, bumping is required)

-

Dimensions:

-

L119*W95*H185CM

-

Use:

-

Battery Spot Welding

-

Voltage:

-

220v, 380V, 3phase 380V±10%

-

Power (kW):

-

8000 W

-

Weight (KG):

-

400 KG

-

Product name:

-

Battery Pack Spot Welding Machine

-

Welding Machine Version:

-

Computer or Touch Screen(Optional)

-

Welder Type:

-

DC welding machine 5000A or 8000A(Optional)

-

Welding Current:

-

5000A/8000A

Quick Details

-

Marketing Type:

-

New Items 2024

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SPTX

-

Rated Capacity:

-

2.5KVA

-

Rated Duty Cycle:

-

30%

-

Max. Welding Thickness:

-

0.3mm(Above 0.3mm, bumping is required)

-

Dimensions:

-

L119*W95*H185CM

-

Use:

-

Battery Spot Welding

-

Voltage:

-

220v, 380V, 3phase 380V±10%

-

Power (kW):

-

8000 W

-

Weight (KG):

-

400 KG

-

Product name:

-

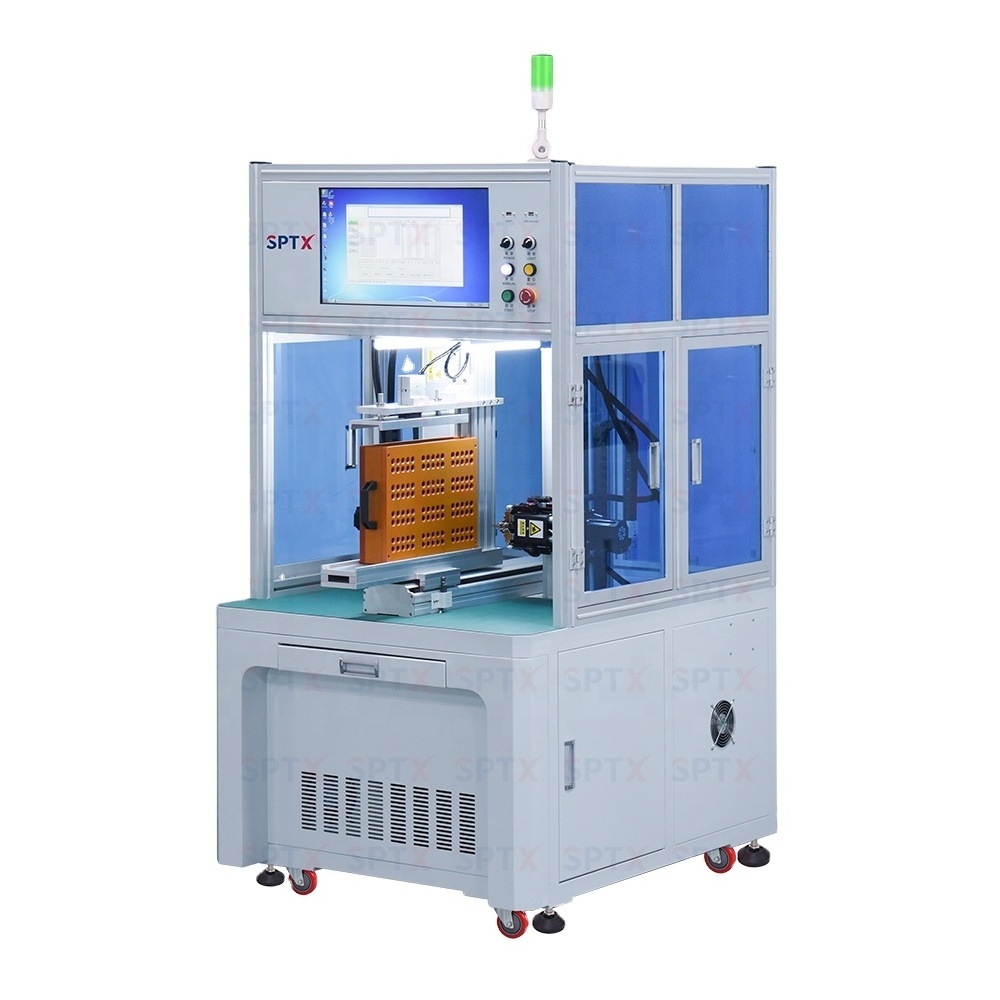

Battery Pack Spot Welding Machine

-

Welding Machine Version:

-

Computer or Touch Screen(Optional)

-

Welder Type:

-

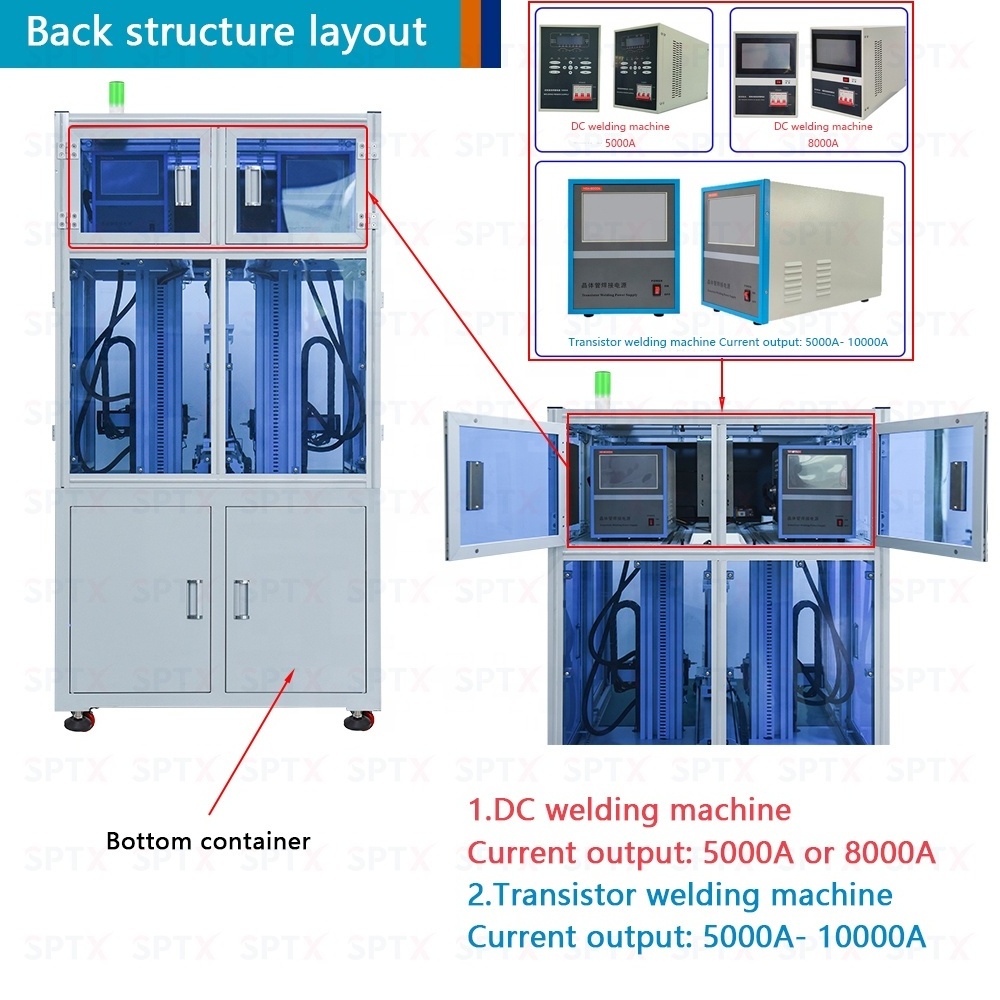

DC welding machine 5000A or 8000A(Optional)

-

Welding Current:

-

5000A/8000A

Contact US freely

Recommend More Products

Other options of battery spot welding machine

Double Side Automatic Battery Pack Spot Welding Machine for Cylindrical

Double Side Automatic Battery Pack Spot Welding Machine is a general platform of automatic processing technology based on microcomputer, suitable battery pack spot welding and assembly in the factory.

The electrical control part of the spot welding machine adopts modular design, with high integration, good versatility and easy maintenance; it mainly performs the traveling mechanism is controlled by servo motor, which has high precision and good reliability; the electrical circuit of the equipment adopts domestic and foreign standards.Control components and devices are easy to maintain and replace. Supports Autocad data import, array and manual methods, which significantly improves spot welding efficiency and ensures the standardization and reliability of spot welding station production in the Pack assembly line.

Details of the Spot Welding Machine

Specifications

|

No |

Item |

Parameter |

|

1 |

Welding power supply |

5000A/8000A Double spot welding power supply(optional) |

|

2 |

Y axis travel |

500MM(customizable) |

|

3 |

Z axis travel |

400MM(customizable) |

|

4 |

Suitable cell type |

18650, 21700, 32650... all types of cylinderial cells |

|

5 |

Cell capacity |

300-600 pcs |

|

6 |

Welding speed |

Max 0.35s/spot, 4500 pcs/h |

|

7 |

Maximum speed of motor transmission |

500mm/s |

|

8 |

Welding material |

Nickel, Nickel-Plated Steel |

|

9 |

Maximum load of cells (18650) |

Y direction:24PCS*Z direction:16PCS |

|

10 |

Welding thickness |

0.1mm-0.5mm,0.2MM or above requires slits and bumps |

|

11 |

Maximum number of stored files |

1000 groups |

|

12 |

Operation system |

Microcomputer and touch screen user interface |

|

13 |

Driver mode |

Motor and precision guide rail |

|

14 |

Cooling |

By air or water (optional) |

|

15 |

Air pressure |

0.4-0.6 Mpa |

|

16 |

Repeatability |

±0.02mm |

|

17 |

Power supply |

Single phase 220V/Three phase 380V |

|

18 |

Power |

8000 W |

|

19 |

Size |

1150L*900W*1750H |

|

20 |

Weight |

400kg |

Structural Analysis Diagram

Product Feature

1.Paired with embedded system, operation is simple. Equipped with solder joint tracking, explosion fire, false welding, leakage welding monitoring records, etc.

2.The welding machine can optionally be equipped with a welding current monitoring system, which can monitor the welding current and has cold solder joint and sealing off alarm.Real-time welding effect monitoring, warning for NG welding spot.

3.Welding needle abrasion alarm, with welding needle usage record, alarm and clearing functions programming interface operation Simple, supports CAD map, array and manual methods. Can store any group of programming files.

4.Rotating and lightweight of the welding head.

5.The pressure of the two welding needle can be adjusted independently.

6.The welding head can be optionally equipped with water-cooling or air-cooling circulation heat dissipation, which can effectively reduce the loss of welding needle and improve the welding effect.

7.It has origin reset and break point continued welding functions, that is, if the machine is shut down due to abnormal problems during the spot welding process, it is optional.Choose to return to the origin or continue welding from the break point.

8.Supports single-point, double-point, and three-point welding modes, and the distance between double-point and three-point is adjustable.

9. The welding specifications can be freely switched according to the welding characteristics of the positive and negative electrodes of the battery to match different energy welding needs.

Machine Dimensions