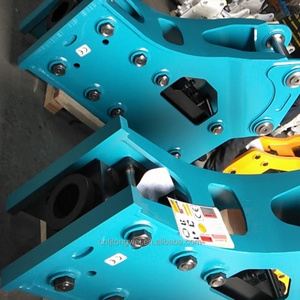

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1800 kg

-

Suitable Excavator(ton):

-

19~26

-

Length:

-

1700mm

-

Core Components:

-

Breaker Hammer

-

Part name:

-

Excavator Hydraulic Breaker Hammer

-

Case:

-

Ultra-wear-resistant steel welded

-

Breaker Hammer Body:

-

Material 42CrMn

-

Shuttle Valve Accumulator etc.:

-

Greatly advance 20%~30% efficiency and reduce counter-acting force

-

Quality:

-

High Quality, Durable, Stable, Safety

-

Packing:

-

Wooden Cases/Wooden Pallet

-

Delivery time:

-

within 3~7 days

-

Certification:

-

CE ISO

-

Application:

-

Construction mining demolition tunnel etc.

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CH

-

Applicable Industries:

-

Excavator

-

Weight:

-

1800 kg

-

Suitable Excavator(ton):

-

19~26

-

Length:

-

1700mm

-

Core Components:

-

Breaker Hammer

-

Part name:

-

Excavator Hydraulic Breaker Hammer

-

Case:

-

Ultra-wear-resistant steel welded

-

Breaker Hammer Body:

-

Material 42CrMn

-

Shuttle Valve Accumulator etc.:

-

Greatly advance 20%~30% efficiency and reduce counter-acting force

-

Quality:

-

High Quality, Durable, Stable, Safety

-

Packing:

-

Wooden Cases/Wooden Pallet

-

Delivery time:

-

within 3~7 days

-

Certification:

-

CE ISO

-

Application:

-

Construction mining demolition tunnel etc.

Details Images

Products Description

Hydraulic Breaker Hammer

-Warranty 12 months

Hydraulic Breaker Hammer for 1~50 Ton Excavator

Q: Are you sure your hydraulic breakers will fit my excavator?

A: Yes, we sure. We have more than 20 years experience in manufacturing hydraulic breakers. Our hydraulic breakers are suitable for excavators of JohnDeere,VOLVO, Hitachi,Komatsu,Doosan, Susitomo,SANY, Cat,KOBELCO,XCMG etc. Show us your excavator model, we confirm the solution.

Q: How about your products warranty?

A:12 months warranty for hydraulic breaker, Free replacement will provide once the failure confirmed caused by our product quality. Beyond the warranty period,Our sales team and Technical Support will response for your question within 24 hours (Holidays Excluded).

A: Yes, we sure. We have more than 20 years experience in manufacturing hydraulic breakers. Our hydraulic breakers are suitable for excavators of JohnDeere,VOLVO, Hitachi,Komatsu,Doosan, Susitomo,SANY, Cat,KOBELCO,XCMG etc. Show us your excavator model, we confirm the solution.

Q: How about your products warranty?

A:12 months warranty for hydraulic breaker, Free replacement will provide once the failure confirmed caused by our product quality. Beyond the warranty period,Our sales team and Technical Support will response for your question within 24 hours (Holidays Excluded).

|

Model

|

UNIT

|

HWX45

|

HWX53

|

HWX68

|

HWX75

|

HWX85

|

HWX100

|

|

Weight

|

Kg

|

130

|

170

|

300

|

400

|

500

|

800

|

|

Length

|

mm

|

1000

|

1070

|

1100

|

1300

|

1400

|

1500

|

|

Working Pressure

|

kg/cm²

|

110-140

|

110-140

|

110-160

|

110-160

|

120-170

|

150-170

|

|

Oil Flow

|

L/min

|

25-40

|

25-45

|

30-45

|

35-65

|

45-85

|

80-120

|

|

Impact Rate

|

bpm

|

550-1000

|

500-900

|

500-800

|

500-700

|

400-700

|

400-700

|

|

Oil hose dia.

|

inch

|

1/2

|

1/2

|

1/2

|

1/2

|

3/4

|

3/4

|

|

Chisel Dia.

|

mm

|

45

|

53

|

68

|

75

|

85

|

100

|

|

Excavator

|

ton

|

1.5-2.5

|

3.0-5.5

|

3.0-7.0

|

6.0-8.0

|

7.0-14

|

11-16

|

|

Model

|

UNIT

|

HWX1350

|

HWX1400

|

HWX1500

|

HWX1550

|

HWX1650

|

HWX1750

|

|

Weight

|

Kg

|

1700

|

1800

|

2400

|

2600

|

3100

|

4100

|

|

Length

|

mm

|

1600

|

1700

|

2800

|

3300

|

3500

|

3800

|

|

Working Pressure

|

kg/cm²

|

180-200

|

180-200

|

180-200

|

180-200

|

200-220

|

200-220

|

|

Oil Flow

|

L/min

|

120-160

|

130-170

|

150-190

|

170-220

|

120-160

|

120-160

|

|

Impact Rate

|

bpm

|

400-700

|

400-600

|

350-500

|

250-400

|

150-300

|

130-200

|

|

Oil hose dia.

|

inch

|

1

|

1

|

1

|

1

|

1 1/4

|

1 1/4

|

|

Chisel Dia.

|

mm

|

135

|

140

|

150

|

155

|

165

|

175

|

|

Excavator

|

ton

|

19-26

|

19-26

|

27-38

|

28-40

|

30-45

|

30-45

|

Why Choose Us

Cylinder

Material

Choose the best Material 20 CrMo 40 CrMo 42Crmo

,

The material of the middle cylinder is made of 20crmo, and is processed by a high-precision CNC center; after the processing is completed,

the cylinder undergoes our leading heat treatment technology. We have our own heat treatment workshop.;

the matching tolerance of the piston and the middle cylinder is within 5-7 wires, and each middle cylinder Both the piston and the piston are cold treated with liquid nitrogen to prevent the cylinder from expanding due to excessive oil temperature and cannot be used normally.

Oil Seal Kits

The oil seal adopts Japanese NOK oil seal

, which is resistant to high temperature and belongs to the best quality oil seal. To

ensure the normal operation period and prolong the service life of the hydraulic breaker, it is necessary to ensure the quality of

the oil seal of the breaker.

ensure the normal operation period and prolong the service life of the hydraulic breaker, it is necessary to ensure the quality of

the oil seal of the breaker.

High quality hammer shell and splint

The material used for the hammer shell and splint is wear-resistant, manganese steel material, to ensure that it will not crack.

We use high-precision product matching, and the matching tolerance is within 1-5 wire, which fully guarantees the hammer's striking strength.

The material of the whole body bolt and splint bolt is 42crmo, and each one is heat-treated to prevent each bolt from being elongated and deformed.

Application

Hot Searches