- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

300

-

Voltage:

-

Suitable for local standard

-

Current:

-

Depends on weld machine

-

Rated Capacity:

-

Depends on weld machine

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

Confirm with us

-

Use:

-

Tank Vessel Pipe automatic welding

-

Equipment:

-

3x6 Column & Booms Welding Manipulator

-

Structure:

-

Column revolve & travel on the rail

-

Reachability:

-

Elevate stroke 3m & stretch stroke 6m

-

Boom end payload:

-

SWL 300KG

-

Weld method:

-

SAW

-

Configuration:

-

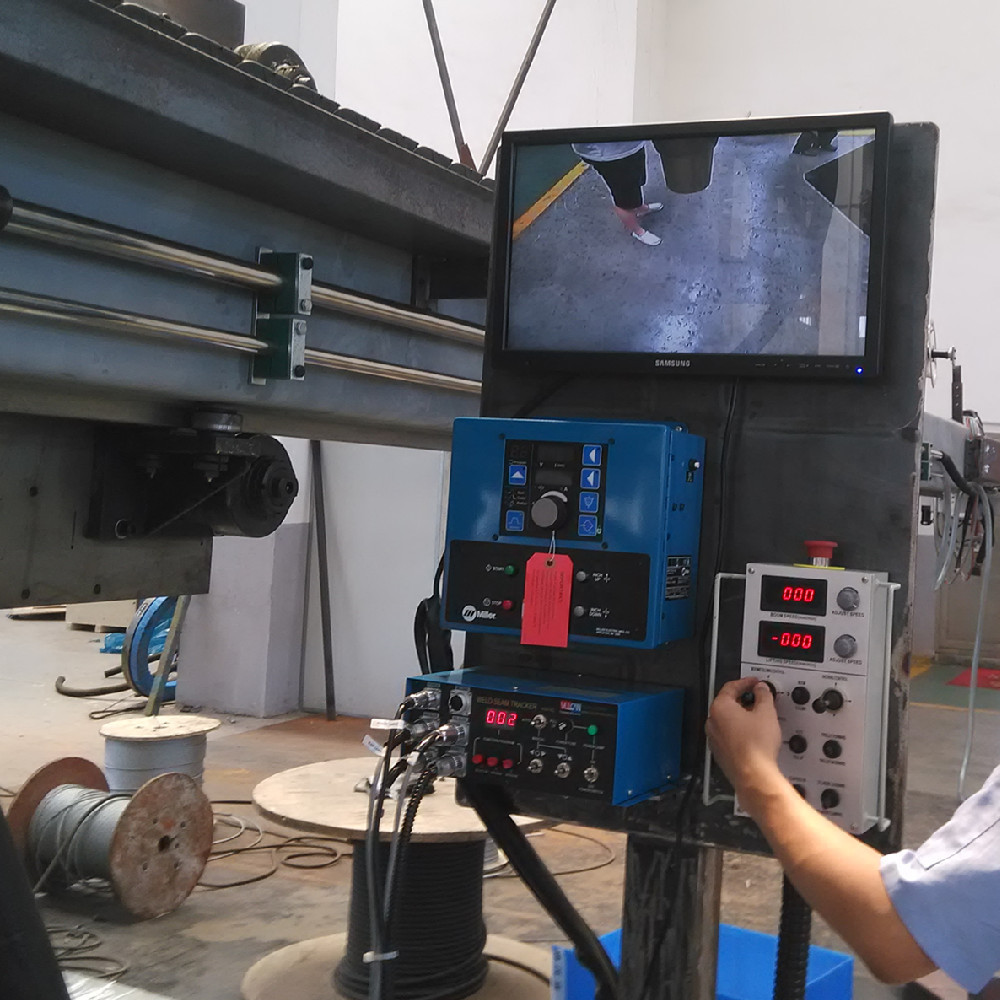

Seam tracker+video surviellance

-

Operation:

-

Central operation on ground

-

Flux recovery system:

-

Included

-

Certification:

-

ISO&CE

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Ronniewell

-

Warranty:

-

13 months

-

Weight (KG):

-

300

-

Voltage:

-

Suitable for local standard

-

Current:

-

Depends on weld machine

-

Rated Capacity:

-

Depends on weld machine

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

Confirm with us

-

Use:

-

Tank Vessel Pipe automatic welding

-

Equipment:

-

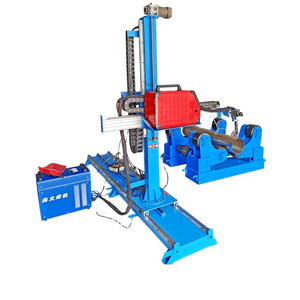

3x6 Column & Booms Welding Manipulator

-

Structure:

-

Column revolve & travel on the rail

-

Reachability:

-

Elevate stroke 3m & stretch stroke 6m

-

Boom end payload:

-

SWL 300KG

-

Weld method:

-

SAW

-

Configuration:

-

Seam tracker+video surviellance

-

Operation:

-

Central operation on ground

-

Flux recovery system:

-

Included

-

Certification:

-

ISO&CE

Seam Tracker Central Operate Tank Tower SAW Column & Booms Auto Welding Manipulator

Brief introduction:

Column & booms welding manipulator with stretch 6m & elevate 3m valid stroke for tank/tower/vessel/pipe heavy duty fabrication;

Equipped with auto seam tracker & video surviellance system, central operation console on the ground;

Feature:

1. Professional auxiliary equipment for welding.

2. Can fitted with various welding power.

3. Boom adopts AC frequency converter stepless speed control and run with steady speed to keep welding quality.

4. Boom head equipped with electric cross slides, can adjust to exact position for welding .

5. Pawl device in boom to guarantee safety once the chain failed and boom dropped down .

6. Customized c olumn & booms are accepted.

7. Column & booms welding manipulator can fitted automatic flux feeding, recovering devices, wire feeder device, working platform and chair.

Technical parameter list:

| Model | LH5060 |

| Structure: |

Travel & Rotation |

| Boom horizontal stroke | 5000mm |

| Boom vertical stroke | 6000mm |

|

Boom horizontal speed :mm/min |

150-1500 |

|

Boom vertical speed : mm/min |

1000 |

|

Boom horizontal motor power :kW |

0.55 |

|

Boom vertical motor power :kW |

2.2 |

| Column rotating angle | ±180° |

|

Column rotating speed - Optional :rpm |

0.75 |

| Column rotating motor-Optional : kW | 0.75 |

|

Column rotating locking method |

By manual |

| Boom end max. loading | 300kg |

| Trolley traveling speed-Optional:mm/min | 3000n |

| Rail inner span(mm)-Optional:mm | G-G2500 |

Description

1. The c olumn & booms welding manipulator is researched, designed and manufactured absorbing domestic and international advanced equipment.

2. Mainly used for big pipe, containers, boilers, pressure vessels, oil tank, wind tower and other cylinders assembly welding.

3. Column & booms welding manipulator can assort all kinds of auto welding or manual welding, improving welding quality, reducing the labor and improving productivity.

4. It can be used together with welding rotator or welding positionerto do inner and outer longitudinal seam and circumferential seam jobs.

O ptional machine:

1. Tandem-twin Submerged Arc Welding machine;

2. Narrow Submerged Arc Welding machine;

3. Arc Tracing unit;

4. Welding oscillator;

5. Flux recovery & convery machine;

6. Lincoln welding power or chinese welding power;

Application

1. Pressure vessels welding

2. Pipe manufacturing industries

3. Wind power fabrication

4. Chemical & fuel storage tank fabrication

5. Any heavy cylindrical welding job