- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

EP

-

Color:

-

as request

-

Module:

-

0.4-8

-

Teeth Type:

-

Spur teeth or Helical teeth

-

Service:

-

Reply in 12 hours at any time

-

Application:

-

Industry Machinery

-

Tooth Profile:

-

Spur Gear Cnc Rack

-

Package:

-

Customers Specific Requirement

-

After Warranty Service:

-

Online support

Quick Details

-

Weight (KG):

-

0.2

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

gear rack

-

Brand Name:

-

EP

-

Color:

-

as request

-

Module:

-

0.4-8

-

Teeth Type:

-

Spur teeth or Helical teeth

-

Service:

-

Reply in 12 hours at any time

-

Application:

-

Industry Machinery

-

Tooth Profile:

-

Spur Gear Cnc Rack

-

Package:

-

Customers Specific Requirement

-

After Warranty Service:

-

Online support

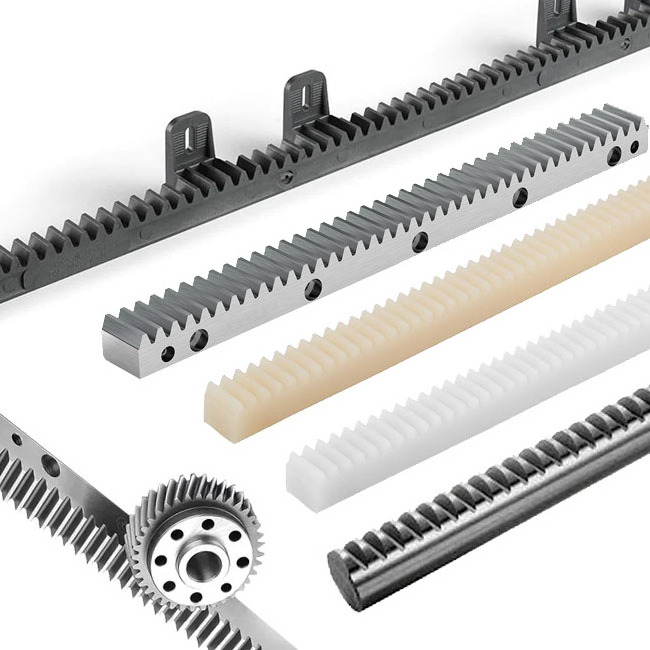

Products Description

Features

1. High precision helical rack, stable and quiet operation

2. Precision pinion can be easily installed to

Ever-power

gearbox

3. The pinion can be pre installed on the transmission

4. Rack and pinion are matched with

Ever-power

gearbox to optimize system performance

5. Accessories include: assembly tool, felt pinion for lubrication and lubrication system

6. Ever-power engineering expertise to choose the best solution for your application

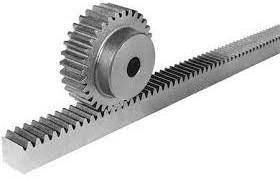

What is Rack & Pinion?

A linear actuator that converts the rotary motion of the (circular) pinion to linear motion at the (linear) rack.

Why use a Rack & Pinion System?

A rack and pinion system is the most cost-effective way for linear movements greater than 2 meters.

Why use a Ever-power Rack & Pinion System?

Ever-power matches the high quality rack and pinion with the best precision gearboxes for your application

The rack can be classified according to tooth shape, gear shape, tooth line shape, manufacturing process and other methods.

|

According to the shape of gears

|

cylindrical gears, straight teeth, helical teeth;

|

|

According to the shape of the tooth line

|

spur gear, helical gear, herringbone gear;

|

|

According to the process

|

quenching, tempering, grinding, gear milling, gear grinding, blackening treatment according to needs

|

Accuracy modulus of rack

At present, the accuracy grade refers to the German standard, with the accuracy of grade 1-13. We generally use 6-stage rack in application. Modular standard rack specifications, of which grade 8 is soft gear and grade 9 is milling gear.

The material is C45 carbon steel, which is widely used in automatic robots, gantry machining centers, laser cutting machines, aluminum profiles, woodworking centers, the seventh axis of trusses and other fields. In this way, the rack generally requires high precision, accurate positioning and stable operation

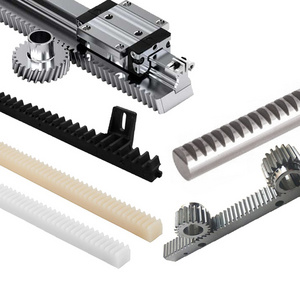

Helical Gear Racks

Straight Gear Racks

Linear Guide Gear Racks

Round Gear Racks

Plastic Gear Racks

Gear Racks for Automatic Door Opener

Application

The working principle of gear and rack is to convert the rotary motion of gear into the reciprocating linear motion of rack, or convert the reciprocating linear motion of rack into the rotary motion of gear.

Related Products

We also supply the following products. If you are interested, you can click on the picture to understand

Hot Searches