- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KSPACK

-

Dimension(L*W*H):

-

$*2*1

-

Weight:

-

5 KG

-

name:

-

corrugated cardboard carton paper box making machine

-

Machine type:

-

Single facer

-

Processing method:

-

heat electrical

-

Rod material:

-

alloy steel

-

Suitable for:

-

single facer corrugated carton making machine

-

Single facer group:

-

mill rol stand , single facer , cutter , single tile paper machine

-

Corrugateed carboard:

-

2 ply 3 ply 5 ply as customer requirement

-

Effective width:

-

1400-2200mm

-

ply:

-

3.5 .7

-

key word:

-

corrugated carton making machine

Quick Details

-

Application:

-

Food, Machinery & Hardware

-

Packaging Material:

-

Paper

-

Voltage:

-

380V or 220V

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KSPACK

-

Dimension(L*W*H):

-

$*2*1

-

Weight:

-

5 KG

-

name:

-

corrugated cardboard carton paper box making machine

-

Machine type:

-

Single facer

-

Processing method:

-

heat electrical

-

Rod material:

-

alloy steel

-

Suitable for:

-

single facer corrugated carton making machine

-

Single facer group:

-

mill rol stand , single facer , cutter , single tile paper machine

-

Corrugateed carboard:

-

2 ply 3 ply 5 ply as customer requirement

-

Effective width:

-

1400-2200mm

-

ply:

-

3.5 .7

-

key word:

-

corrugated carton making machine

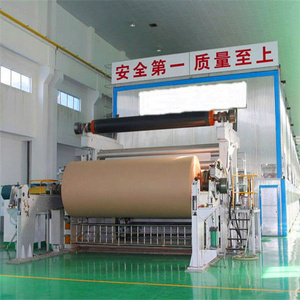

Automatic single face e flute corrugated cardboard carton paper box products making machine

The 2 layer corrugated paper machine production line is the ideal and perfect equipment for small or medium carton factories.This corrugated paper line consists of three machines. There are roll stand , single face 2 layer corrugated machine and sheet cutter .It is known as the heart of the "corrugated cardboard production line".It is the key equipment from single-layer paper to double-layer corrugated paper . The production line has rational structure design, advanced producing flow, high efficiency, strong batch adjustable, easy operation, etc. good work conditions.

Single facer groups include : mill roll stand , 2 ply single facer , cutter, single tile paper machine

1. Mill roll stand : single facer fully automatic corrugated box machine

(Also named corrugated carton making machine)

|

Structural features: symmetrical structure can be installed at the same time two bundles of paper tube, can be used for non-stop machine to change the paper electric o clamping, release, moving on the left and right brake adjustment using disc plate system. with two-stage automatic expansion of the paper clip, clamp head size 3 inch |

|

TECHNICAL PARAMETER 1. paper stand active model: Mechanical electrical 2.clamp paper scope : max 1400mm , min 100mm 3.clamp diameter : max 1400mm 4.single side max load weight : 1500kgs 5.power : 380 volt ,50hz 6.Turn over motor power : 1.5kw /set clamp motor power : 0.75kw 4 set 7.manual brake model ( option pneumatic brake model ) 8.electric brand : DELIXI CHIT 9. machine weight : 2.3T |

2. 2 ply single facer : single facer fully automatic corrugated box machine

(Also named corrugated carton making machine)

|

Characteristics 1. Cover vacuum s uction. 2. Corrugating roll is made of high qualit y alloy steel4 8CrMo, the surface is medium-frequency quenched and chrome-plated. Hardness can reach HRC55~60, which ensures good wear-resistance and long life service. 3. No gear transmission. 4. Glue roll is lifted and lowered pneumatically. 5. Independent glue clean device and electric glue-separate board to control the width of glue. 6. Manually regulate or electrically regulate the display device. 7. Lubricated by high temperature lubricate grease. 8. Surface of all dancing rolls and preheating rolls is grinded and chrome-plated. 9. Pressure roll is medium- frequency quenched and chrome-plated. 10. Width 1200mm~2000mm. 11. Preheating rolls, pressure rolls and corrugating rolls all meet the National Standard of Pressure Vessel. Working pressure is 1.1MPa. |

Technological Parameters

|

Working Width |

1200mm |

|

|

Heating method |

electrical heating |

|

|

Design speed |

80m/min |

|

|

Economical speed |

45-60 m/min |

|

|

Compress-air pressure |

0.4-0.9MPa |

|

|

Flute type |

Standard flute |

UVE Flute |

|

Standard spec. |

E |

|

|

For other type and model, we can produce as customer’s requirement. |

||

|

Corrugated roll diameter (mm) |

280 |

|

|

Wall Thickness (mm) |

130 |

|

3.Sheet cutter : single facer fully automatic corrugated box machine

(Also named corrugated carton making machine)

Rotary sheet cutter is important unit of the single facer group ,it slit the corrugated paper . adopt the Continuously Variable Transmission tech which developed technicial in china and foreign ,

And manual controlable system ,adopt the mechnical system slit the paper ,rise the products efficiency .reduced the work strength

1.From coil to 2 layer board machine series ( This machine groups introduced as shown above)

-roll stand

-single face machine

-sheet cutter

1. from 2 layer board to 3 layer or 5 layer board machine series

-laminating machine

-pasting machine

-pressing machine

-thin blade machine

2. from 3 layer or 5 layer corrugated board to corrugated flat box machine series

-carton box printing slotting die cutting machine

3. from corrugated flat box to three-dimensional box machine series

-stand shape fold glue machine

-Hook bottom machine

-4 -6 corner fold glue machine

-stitching machine

1. What is power of heating tube

There is glass tube heating, each 4KW

There are also stainless steel heating tubes, each 3KW

2.What is characteristics of heating tube

The characteristics of glass heating tube: heating block, not bend, easy to be broken in transportation

Features of stainless steel heating tube: convenient transportation, easy to bend when heating

3.What is the Electric heating machine consumption

glue adjust gap motor 0.2kw ,main motor 7.5kw , fan 7.5kw ,electrical pipe 4kw/pcs ( 16 pcs)

Total 79.2 KW

4. What is the steam heating machine consumption

fan 7.5KW , main motor 7.5KW , the pump 0.75KW

( If add electrical adjust function , need add 0.37kw )

Total 15.5 KW

5. How to calculate the consumption of working hours

The power consumption measure unit is KW/hour .

If want to know 8 hour consumption , the formula is Power*8*60% .

6.What is the consumption of sheet cutter

Light type sheet cutter: 2.2KW

Improved sheet cutter : 2.2KW or 3 KW

Heavy type sheet cutter : 4 KW

Computer type sheet cutter : 6.2 KW

Stacker power : 2.2 KW